Rotor structure of permanent magnet coreless motor

A technology with a rotor structure and no iron core, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of silicon steel sheet consumption, large starting current of motor, low efficiency, etc., and reduce shaft The effect of small size, low running noise and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

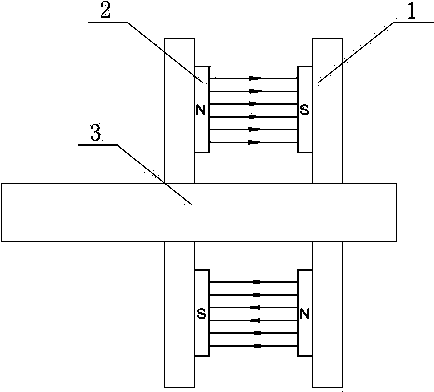

[0011] like figure 1 As shown, a rotor structure of a permanent magnet ironless motor comprises two magnetic yokes 1 on which a plurality of magnets 2 are arranged. The disk surfaces of the yokes are parallel to each other, the magnets on the two yokes are opposite to each other, the magnetic poles on the adjacent magnets 2 are opposite in polarity, an axial magnetic field is formed between the magnets 2 on the two yokes 1, and the magnets on each yoke 1 Several magnets are arranged on the magnetic yoke alternately and evenly according to N poles and S poles and surround a circle.

[0012] When using the rotor structure of the present invention to assemble the motor, the two yokes are set on the main shaft 3, and a stator with an iron-free structure is installed on the main shaft and is located between the two yokes. Since the two yokes form an axial Magnetic field, the electric wire cuts the magnetic induction line vertically in the rotor magnetic field, which can make the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com