Main and auxiliary generator overhauling process

A generator and process technology, applied in the direction of manufacturing motor generators, electrical components, electromechanical devices, etc., can solve the problems that there is no maintenance process for the main and auxiliary generators of HXN5 locomotives, and achieve the goal of improving the quality of maintenance, repairing faults, and eliminating hidden dangers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and attached Figure 2-5 It will be described in further detail, but the embodiments of the present invention are not limited thereto.

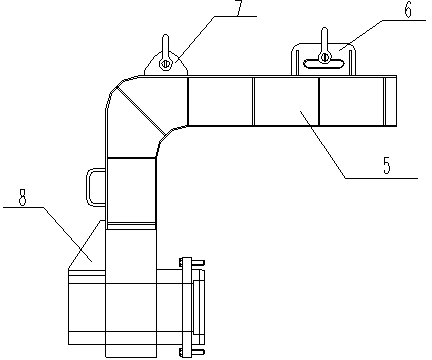

[0027] Such as figure 2 As shown, the maintenance process flow chart of the present invention, its maintenance process is: appearance inspection - removal of slip ring - motor disintegration, wherein, after the motor is disassembled, each component is subjected to separate maintenance, including: slip ring maintenance, rotor insulation treatment, rotor Screw hole inserting, end cover crack welding repair and auxiliary stator transformation, after the repair of each component, the motor assembly-insulation test is passed-out of the section.

[0028] When implementing, carry out routine visual inspection and cleaning first.

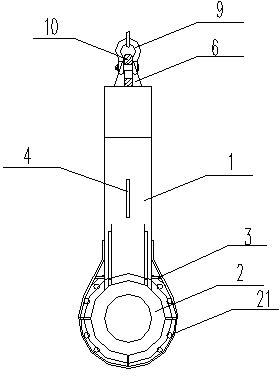

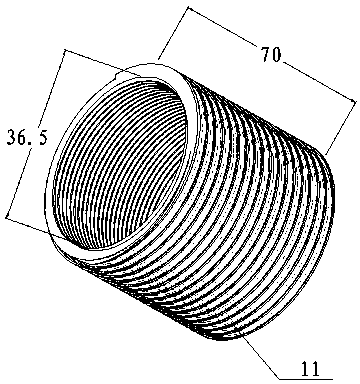

[0029]After the routine visual inspection, the slip ring is removed, and the self-made slip ring pull-out tooling is used for removal. The tooling has won the national patent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com