Integrated circuit package having a split lead frame

A technology of lead frame and lead wire, which is applied in the direction of circuits, measuring devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

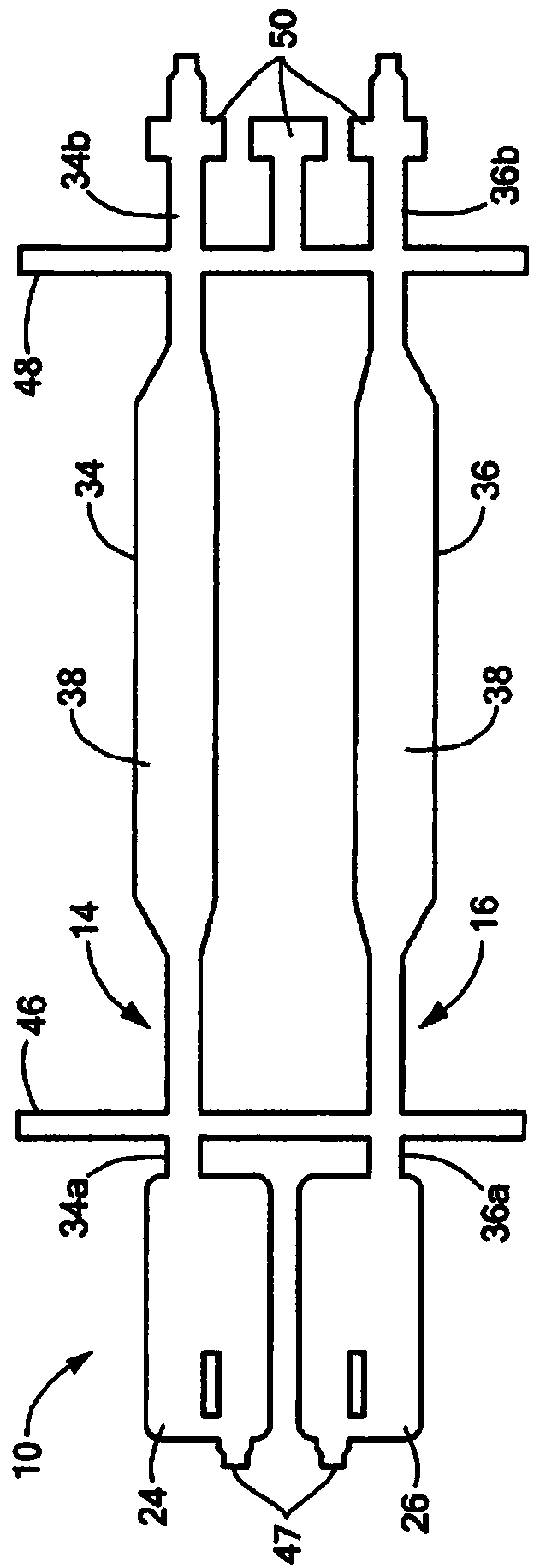

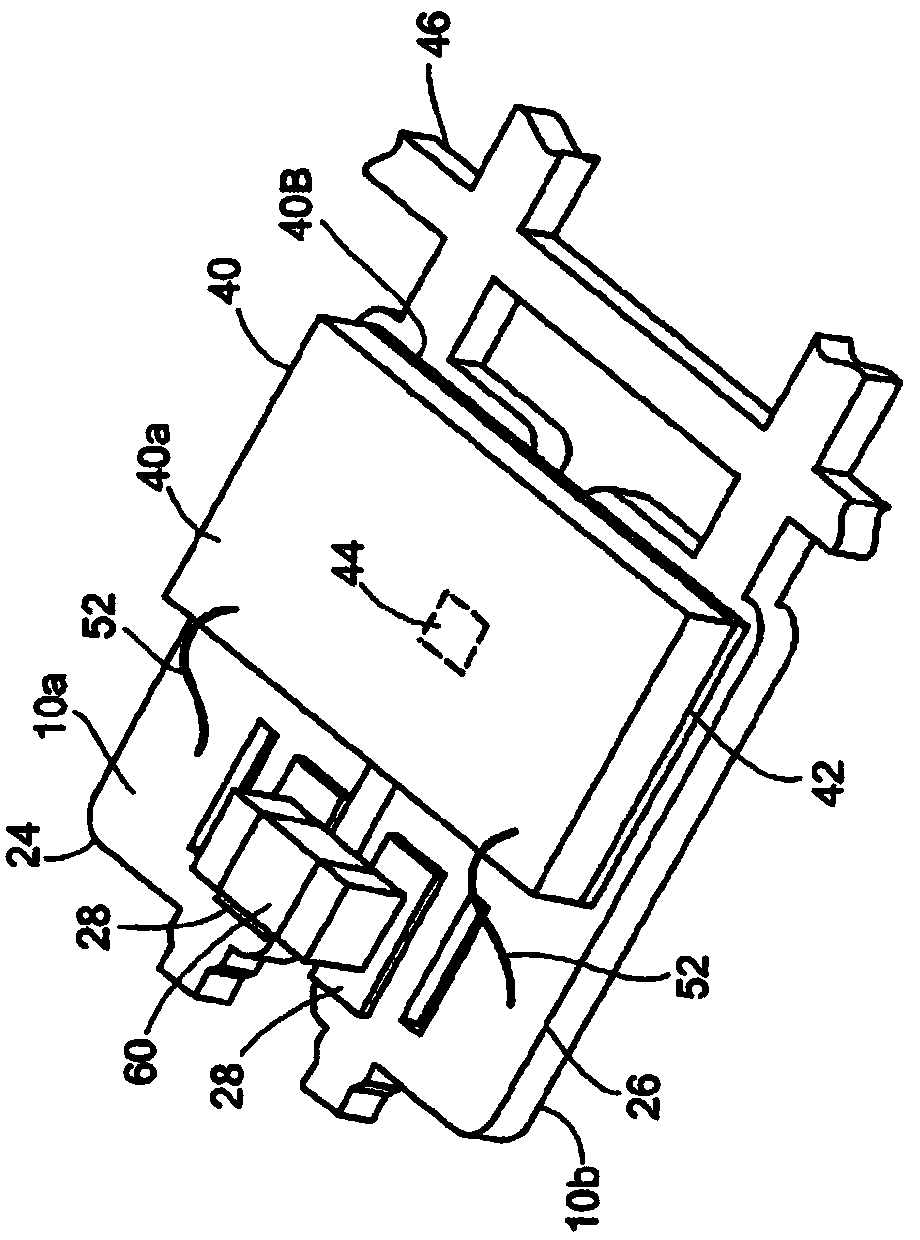

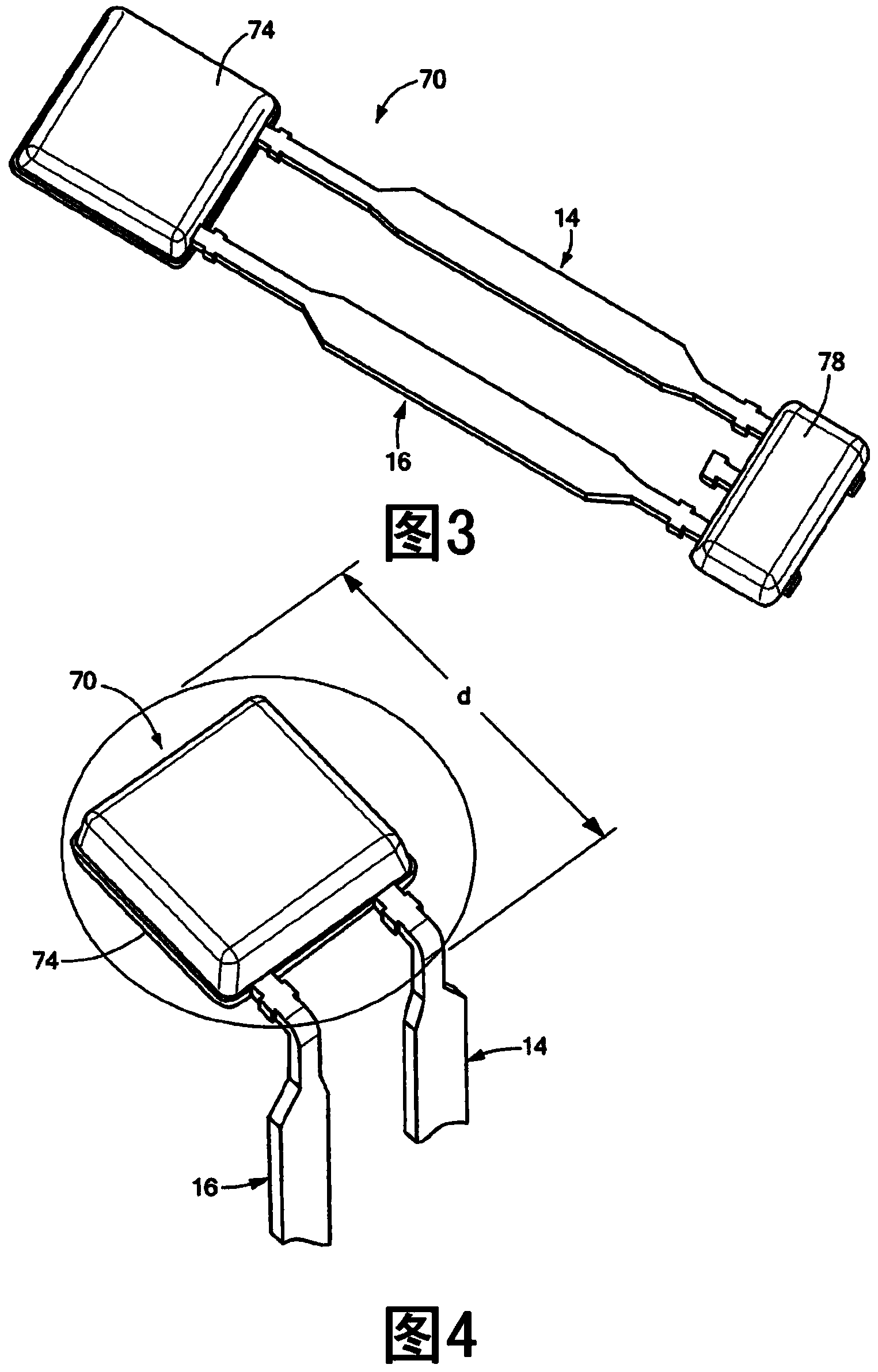

[0035] refer to figure 1 , a leadframe 10 for use in an integrated circuit includes a plurality of leads 14, 16, at least two of which (and here, the two illustrated leads comprising said plurality of leads) include respective bare The sheet attaching portions 24 , 26 and the connecting portions 34 , 36 . The lead frame 10 has a first surface 10a and an opposite second surface 10b ( figure 2 ). As will be explained, the die attach portion 24, 26 (sometimes referred to herein simply as the die portion) of each lead may have a semiconductor die ( figure 2 ).

[0036] The connection portion 34, 36 of each lead extends from a first end 34a, 36a adjacent the respective die portion 24, 26 to a second, distal end 34b, 36b remote from the die portion. Typically, the connecting portion 34, 36 of each lead is elongated and adapted to form an electrical connection to electronic systems and devices (not shown), such as a power supply or microcontroller, located outside the integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com