Strawberry picking end effector and working process thereof

An end effector and strawberry technology, which is applied to picking machines, agricultural machinery and tools, and applications, can solve problems such as reducing operating efficiency, reducing mechanical tolerance capabilities, increasing time consumption of image recognition and segmentation, and achieving improved positioning. Accuracy and speed, reducing algorithm complexity and time consumption, improving the effect of picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

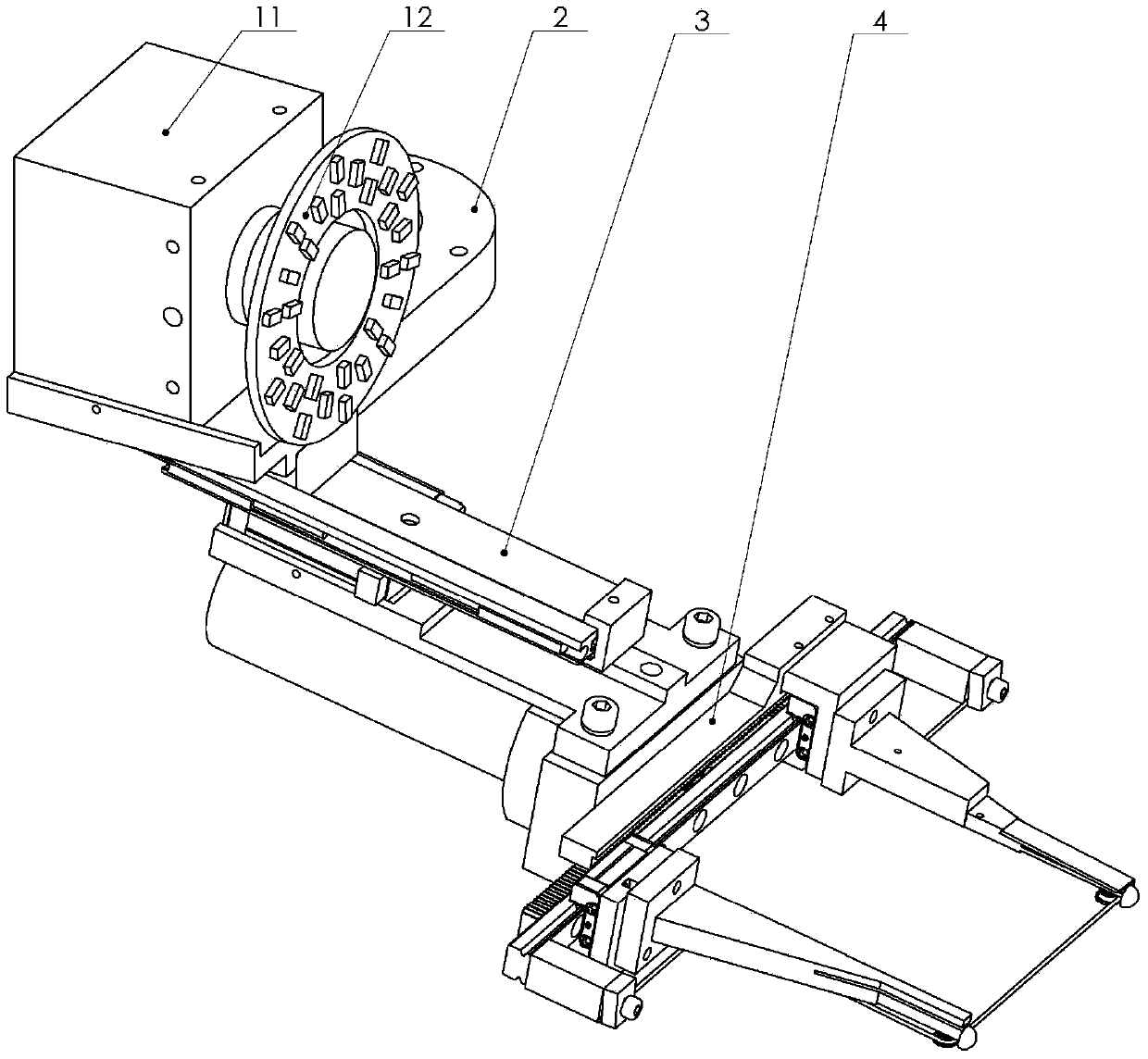

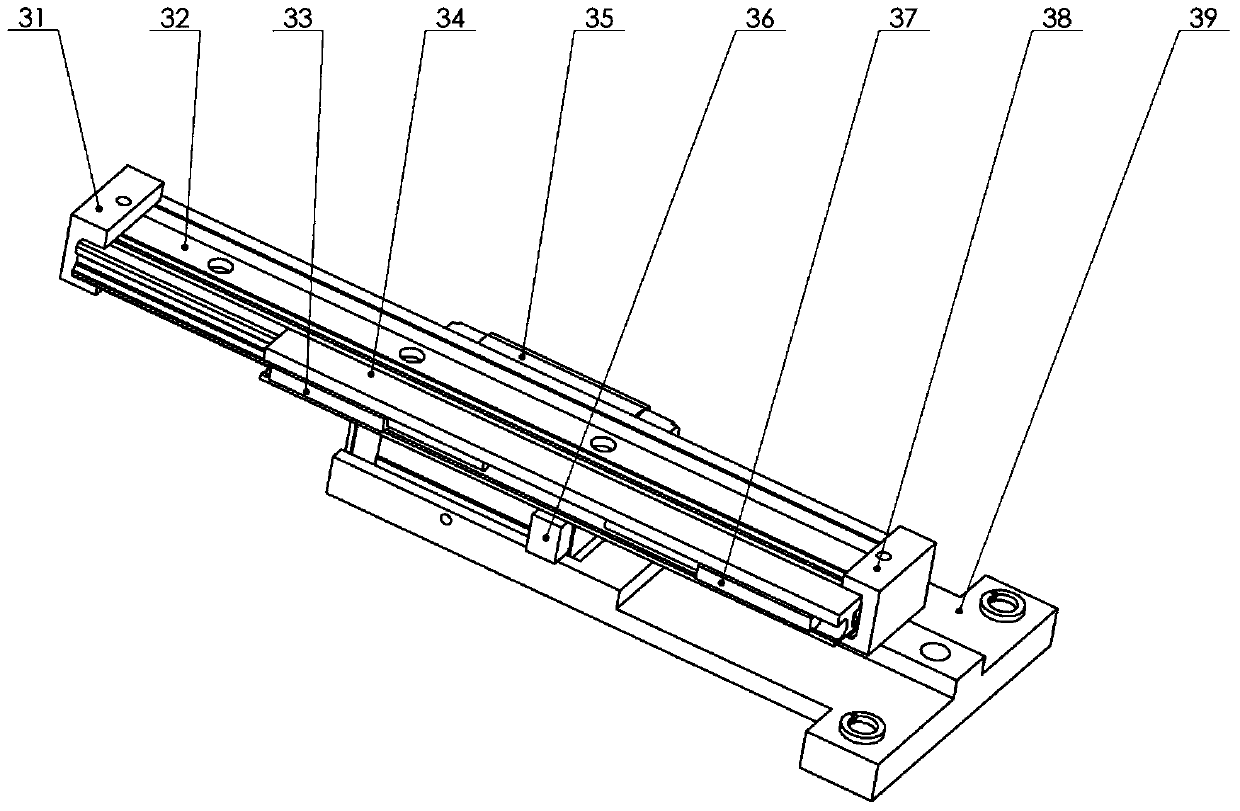

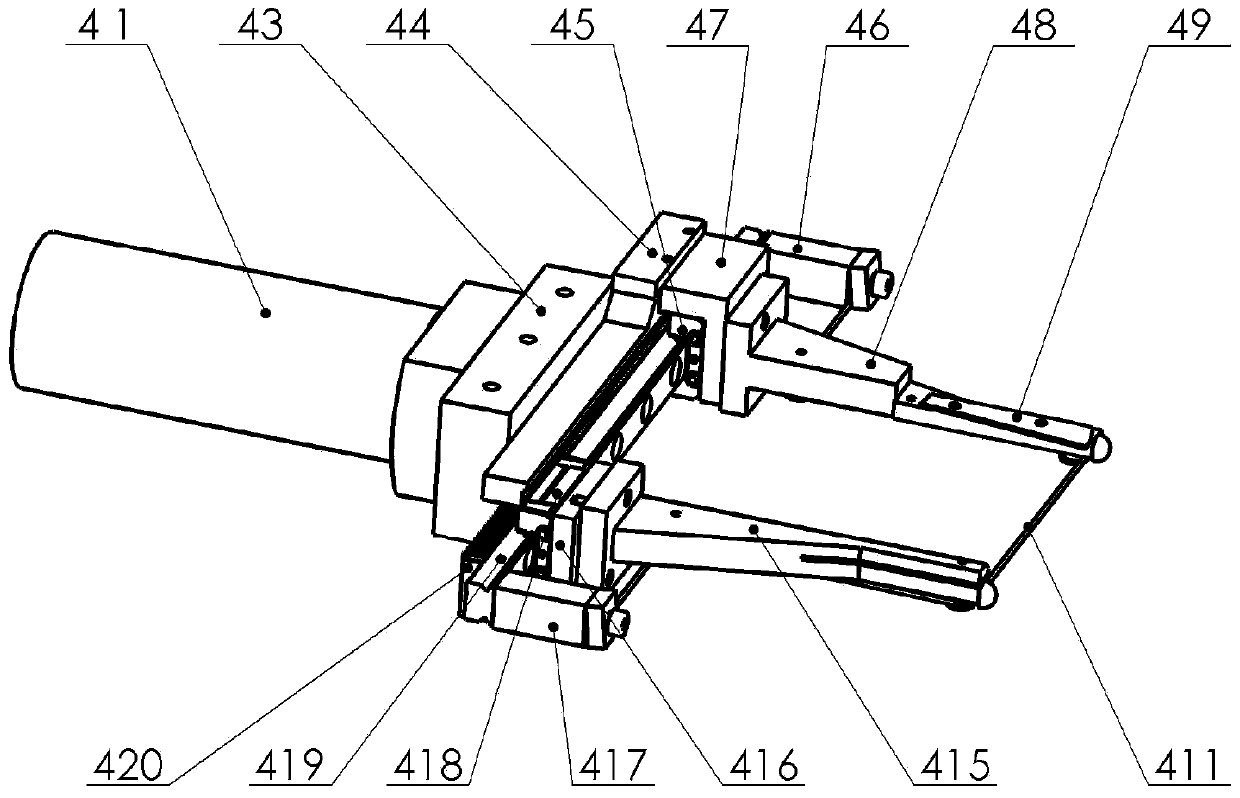

[0071] like figure 1 shown, is the overall schematic diagram of the strawberry picking end effector of the present invention, figure 2 is the schematic diagram of the ridge wall sensing unit of the present invention, image 3 is a schematic diagram of the mechanical claw of the present invention, Figure 4 is an exploded view of the mechanical claw, Figure 5 is the schematic diagram of the mechanical claw drive execution of the present invention, Image 6 This is a front view of the gripper of the present invention.

[0072] like figure 1 As shown, the end effector includes a camera unit, a mechanical claw connecting block 2, a ridge wall sensing unit 3 and a mechanical claw 4; wherein, the camera unit includes a camera 11 and a light source 12, and the camera 11 is arranged on the mechanical claw connecting block 2 The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com