Food shovel disc mold striping machine

A demoulding machine and food technology, which is applied in the field of demoulding machines, can solve the problems of heavy weight, high oil content, and reduced demoulding production efficiency, so as to achieve the effects of improving work efficiency, flexible adjustment, and ensuring hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

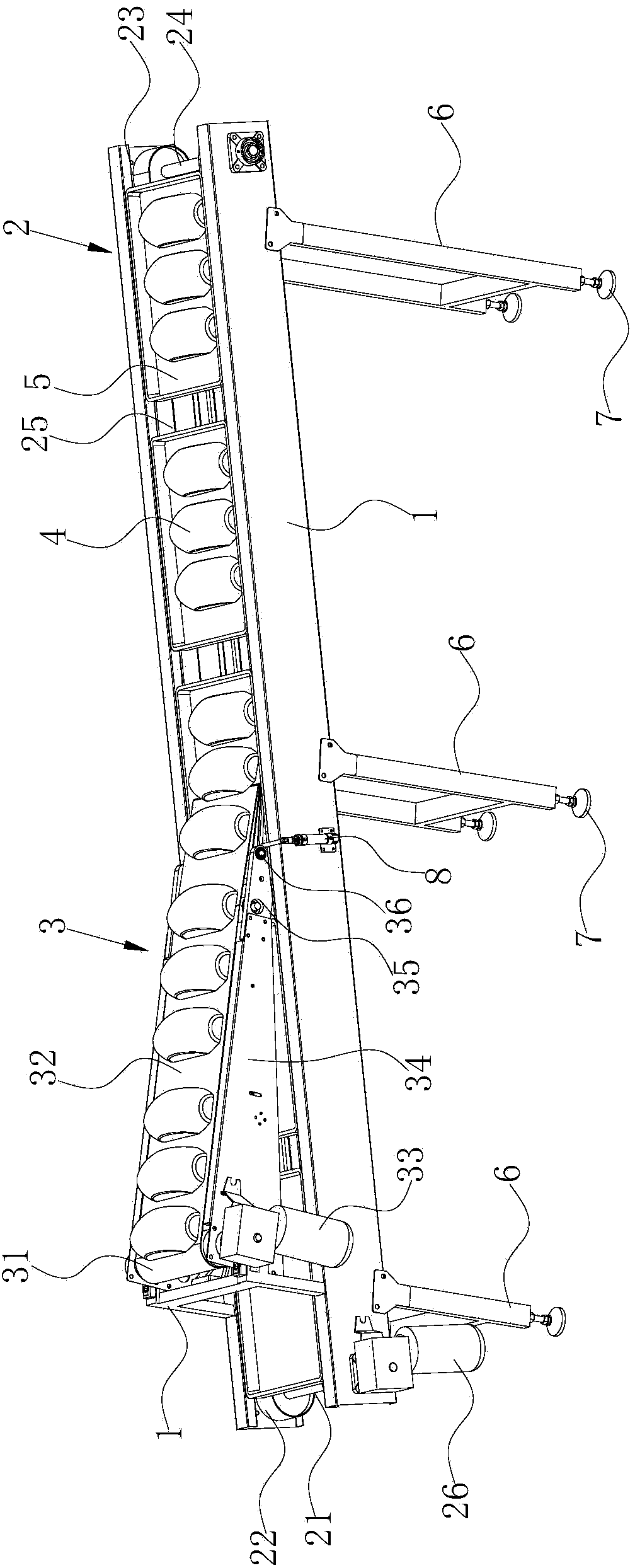

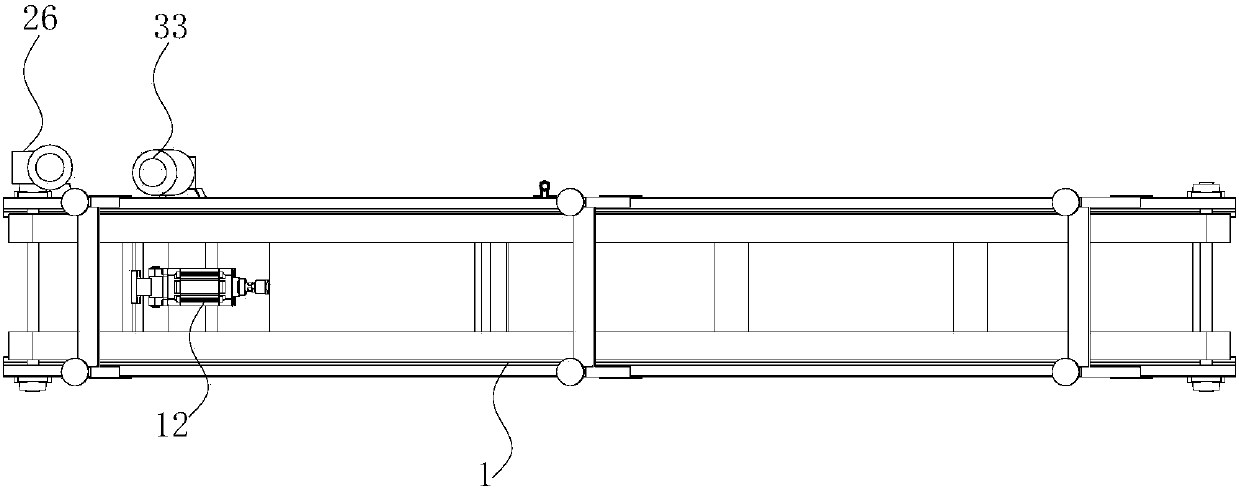

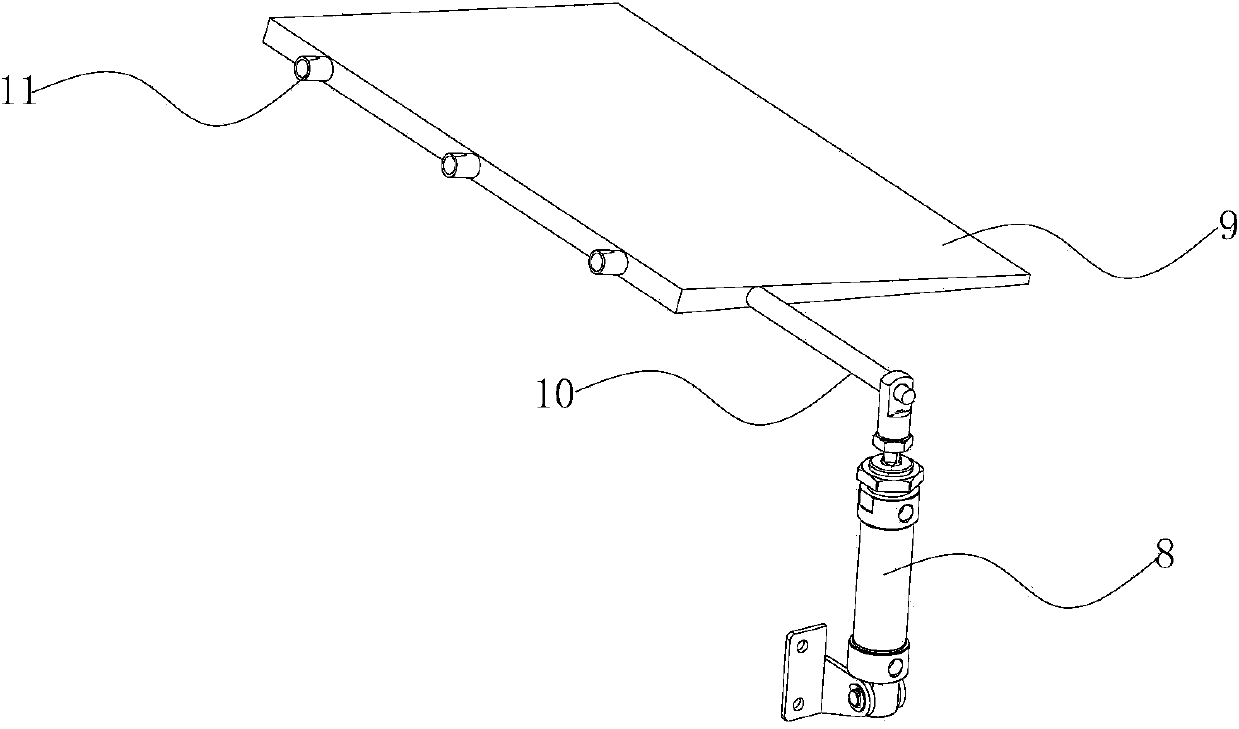

[0017] Such as Figure 1-3 As shown, it is a food shovel stripping machine of the present invention, including a baking tray 5 for carrying food 4, a frame 1, a baking tray conveying device 2 installed on the frame 1 and used to transport the baking tray 5, The first air cylinder 12, the second air cylinder 8, the food transmission device 3 for receiving food 4 from the baking pan 5 of the baking pan conveying device 2, the food transmission device 3 is pivotally connected to the frame 1 through a first pivot , the first cylinder 12 is used to drive the food transmission device 3 to rotate around the first pivot, the first pivot is located above the baking tray conveying device 2, and the food 4 receiving end of the food transmission device 3 passes through the first Two pivots 36 are pivotally connected with a food receiving plate 9, and the second cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com