LED spectrum convertible composite light diffusion plate and production method

A production method and composite light technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve inconvenient processing and production work, inconvenient surface cleaner foam removal, light effect, haze and Poor light transmittance and other problems, to achieve the effect of facilitating process production, eliminating surface foam, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

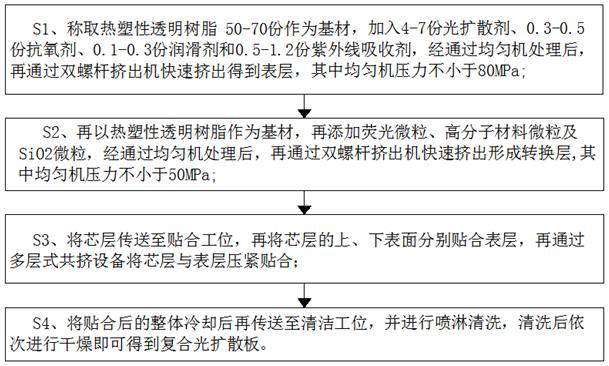

[0056] A composite light diffusion plate with switchable LED spectrum, such as figure 1 Shown, its production method comprises the following steps:

[0057] S1. Weigh 50 parts of thermoplastic transparent resin as the base material, add 5 parts of light diffusing agent, 0.4 part of antioxidant, 0.1 part of lubricant and 0.5 part of ultraviolet absorber, process it through a homogenizer, and then pass it through a twin-screw extruder Quickly extrude to obtain the surface layer, where the uniform machine pressure is not less than 80MPa;

[0058] S2. Then use thermoplastic transparent resin as the substrate, and then add fluorescent particles, polymer material particles and silicon dioxide (SiO 2 ) particles, processed by a homogenizer, and then quickly extruded through a twin-screw extruder to form a conversion layer, wherein the pressure of the homogenizer is not less than 50MPa;

[0059] S3. Transfer the core layer to the bonding station, then respectively bond the upper and...

Embodiment 2

[0064] A composite light diffusion plate with switchable LED spectrum, such as figure 1 Shown, its production method comprises the following steps:

[0065] S1. Weigh 60 parts of thermoplastic transparent resin as the base material, add 6 parts of light diffusing agent, 0.5 part of antioxidant, 0.2 part of lubricant and 0.7 part of ultraviolet absorber, process it through a homogenizer, and then pass it through a twin-screw extruder Quickly extrude to obtain the surface layer, where the uniform machine pressure is not less than 80MPa;

[0066] S2. Then use thermoplastic transparent resin as the substrate, and then add fluorescent particles, polymer material particles and silicon dioxide (SiO 2 ) particles, processed by a homogenizer, and then quickly extruded through a twin-screw extruder to form a conversion layer, wherein the pressure of the homogenizer is not less than 50MPa;

[0067] S3. Transfer the core layer to the bonding station, then respectively bond the upper and...

Embodiment 3

[0072] A composite light diffusion plate with switchable LED spectrum, such as figure 1 Shown, its production method comprises the following steps:

[0073] S1. Weigh 70 parts of thermoplastic transparent resin as the base material, add 7 parts of light diffusing agent, 0.4 part of antioxidant, 0.3 part of lubricant and 0.9 part of ultraviolet absorber, process it through a homogenizer, and then pass it through a twin-screw extruder Quickly extrude to obtain the surface layer, where the uniform machine pressure is not less than 80MPa;

[0074] S2. Then use thermoplastic transparent resin as the substrate, and then add fluorescent particles, polymer material particles and silicon dioxide (SiO 2 ) particles, processed by a homogenizer, and then quickly extruded through a twin-screw extruder to form a conversion layer, wherein the pressure of the homogenizer is not less than 50MPa;

[0075] S3. Transfer the core layer to the bonding station, then respectively bond the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com