Log processing system capable of improving efficiency and reducing staff

A technology for processing systems and logs, applied in wood processing appliances, manufacturing tools, band saws, etc., can solve the problems of time-consuming and labor-intensive, large amount of personnel, long manual transfer distance, etc., to reduce manual operation, reasonable configuration, and economical The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

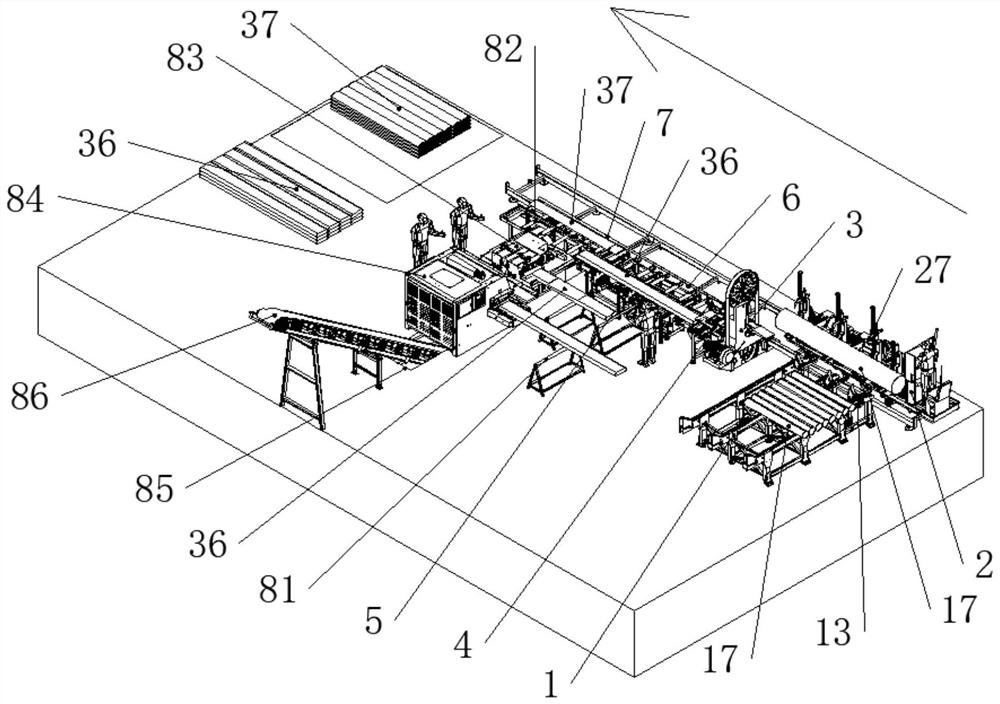

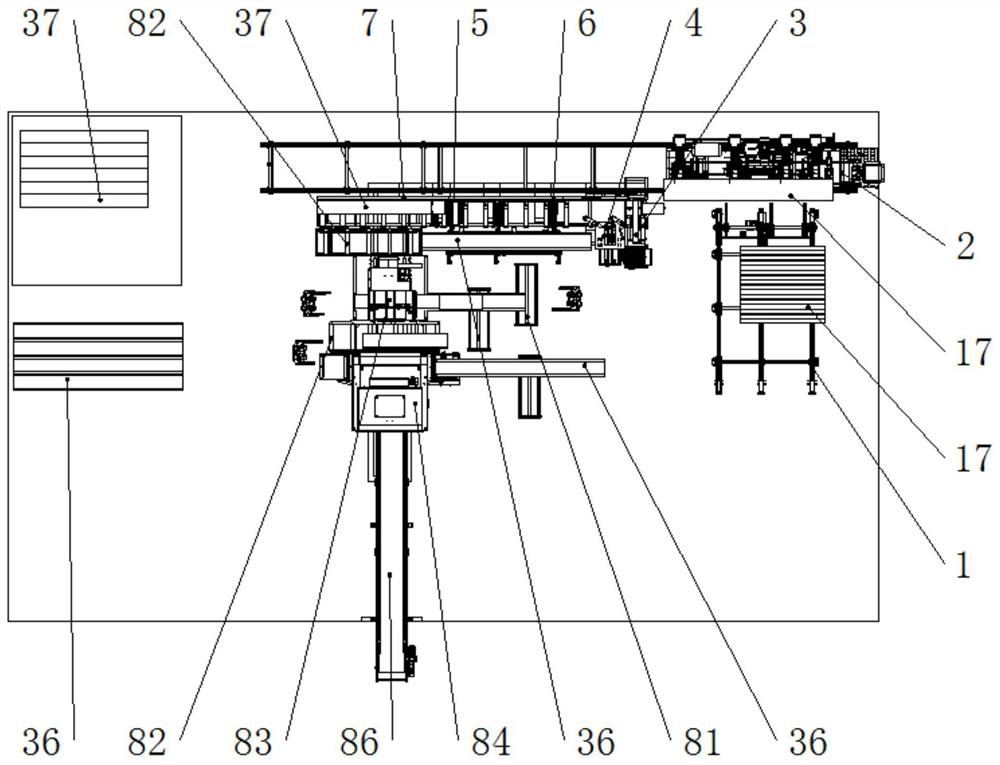

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

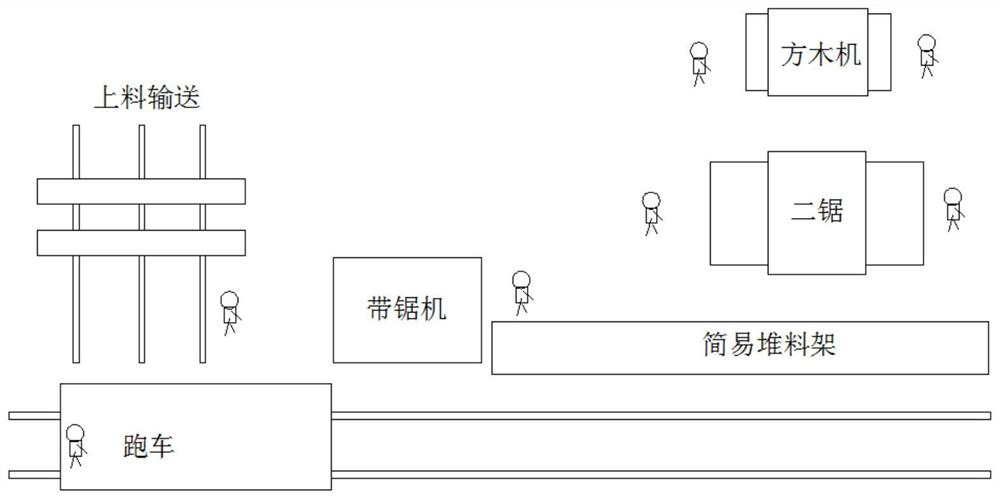

[0052] in, figure 2 The arrow direction in represents the log 17 sawing direction.

[0053] see Figure 2-24 , a log processing system that increases efficiency and reduces personnel, including a feeder 1, a sports car 2, a vertical band saw machine 3, a material holding device 4, a side shifting conveying device 5, a conveyor belt, a material board transition frame 81, and a return material Conveyor frame 82, edge cleaning and material modification integrated machine 83, square wood multi-blade sawing machine 84, pit 85 and sawdust conveyor belt 86; the feeder 1 is located on the side of the sports car 2; The band saw machine 3 and the conveyor belt are sequentially arranged behind the feeder 1; the holding device 4 is arranged above the front outer side of the conveyor belt; the side shift conveyor 5 is arranged on the conveyor belt The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com