Automated die cleaning machine

A technology for cleaning machines and molds, applied in the field of cleaning machines, can solve the problems of low production efficiency, environmental pollution, time-consuming and labor-intensive, etc., and achieve the effects of reducing labor intensity, good environment, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

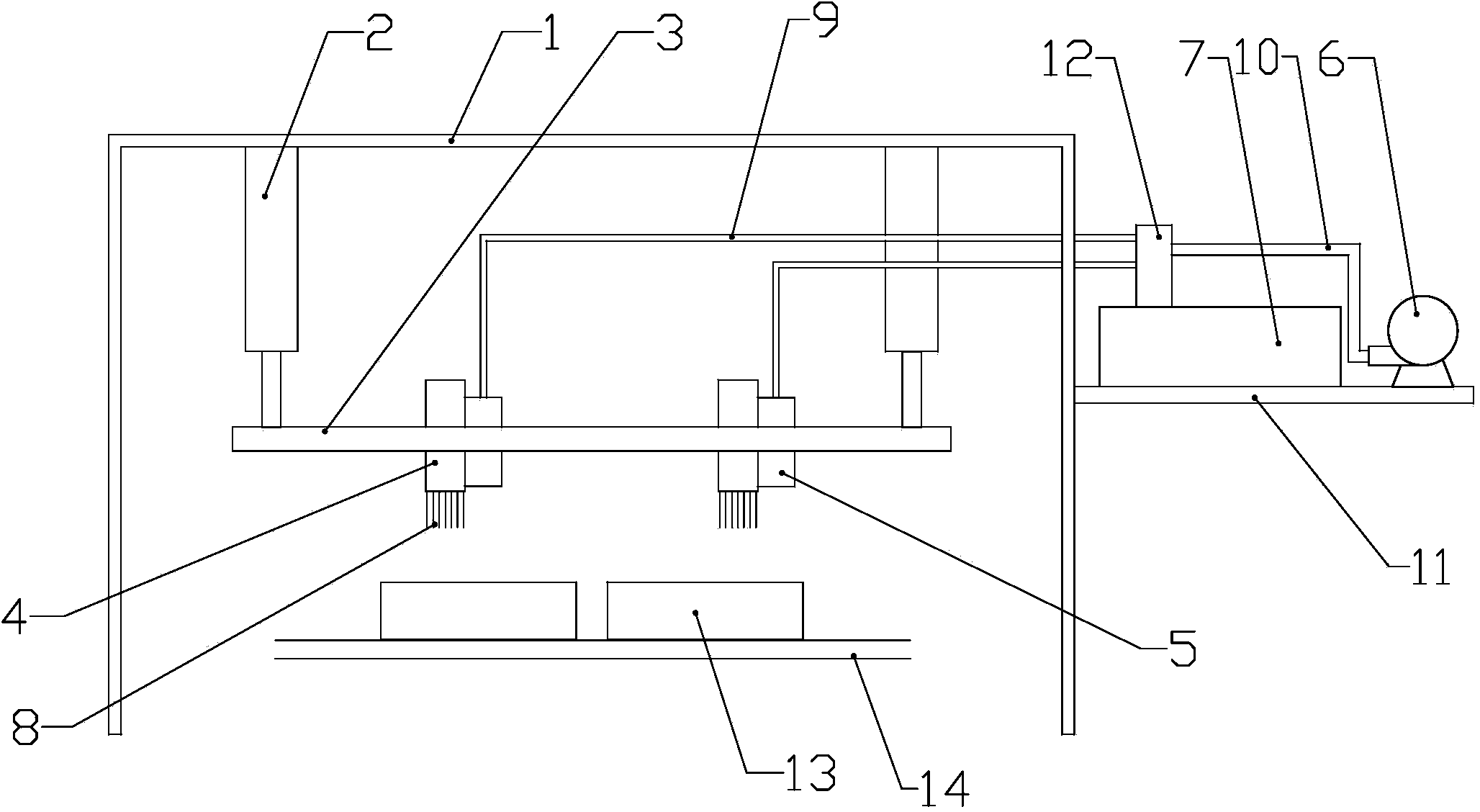

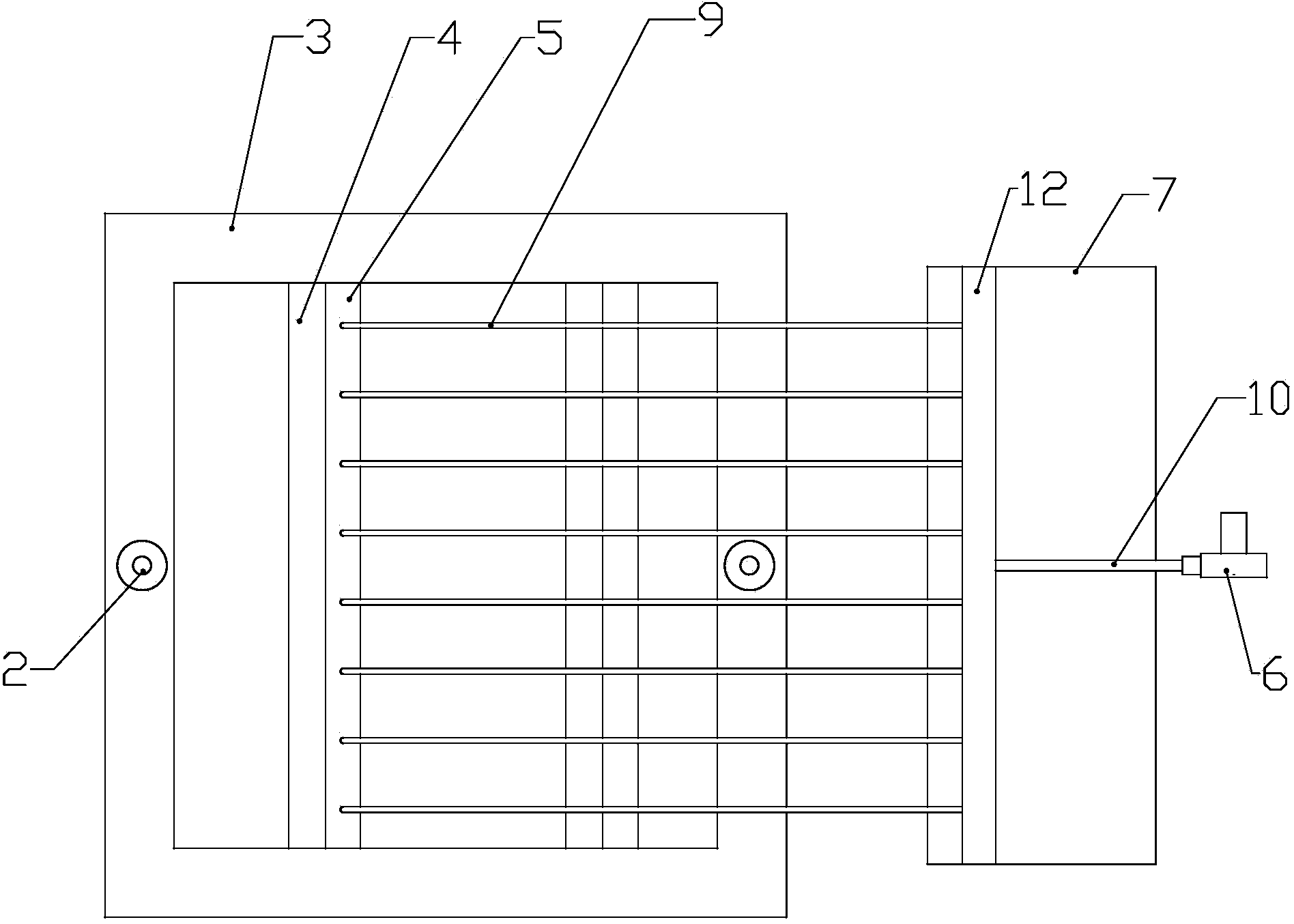

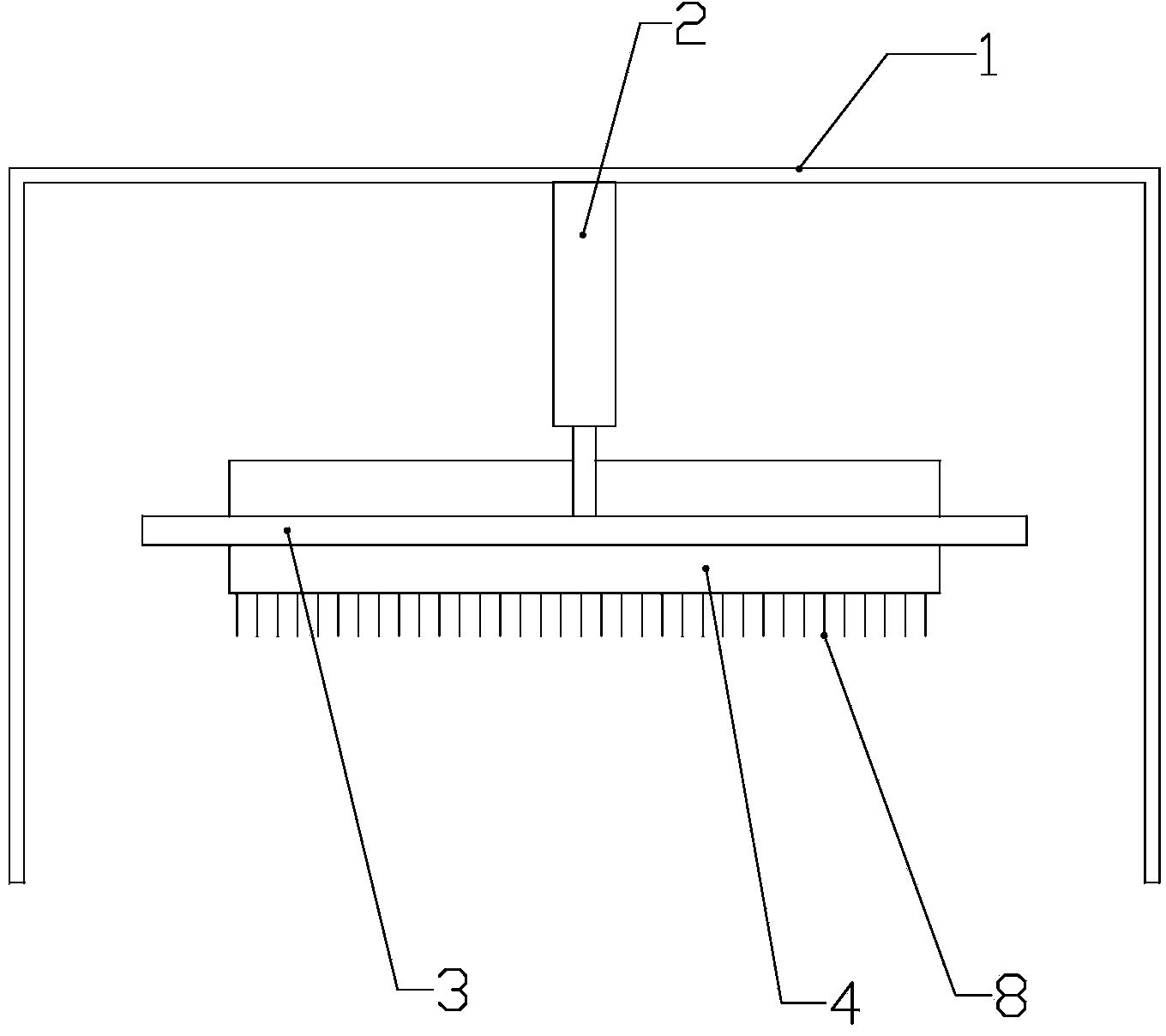

[0016] Refer to the attached figure 1 , attached figure 2 And attached image 3 The automatic mold cleaning machine of the present invention is described in detail below.

[0017] The automatic mold cleaning machine of the present invention has a structure comprising a cleaning machine support 1, a cleaning machine lifting cylinder 2, a cleaning brush fixing plate 3, a cleaning brush 4, an ash absorber 5, a blower fan 6 and a garbage collection box 7;

[0018] The lifting cylinder 2 of the cleaning machine, the cleaning brush fixing plate 3, the cleaning brush 4 and the ash absorber 5 are respectively arranged in the cleaning machine support 1, and the cleaning brush 4 is arranged on the cleaning brush fixing plate 3, and the cleaning brush The bottom of 4 is provided with bristle 8, and the top of described cleaning brush fixed plate 3 links to each other with cleaning machine support 1 top by cleaning machine lifting cylinder 2, and cleaning machine lifting cylinder 2 top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap