Product taking-out device and method of vacuum die casting machine and vacuum die casting machine

A vacuum die-casting and product take-out technology, which is applied to the product take-out device of vacuum die-casting machines and the field of vacuum die-casting machines, can solve the problems of prolonging the production cycle of amorphous alloy products, affecting production efficiency, and bulky volume, so as to reduce impact and improve quality products rate, to avoid the effect of oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

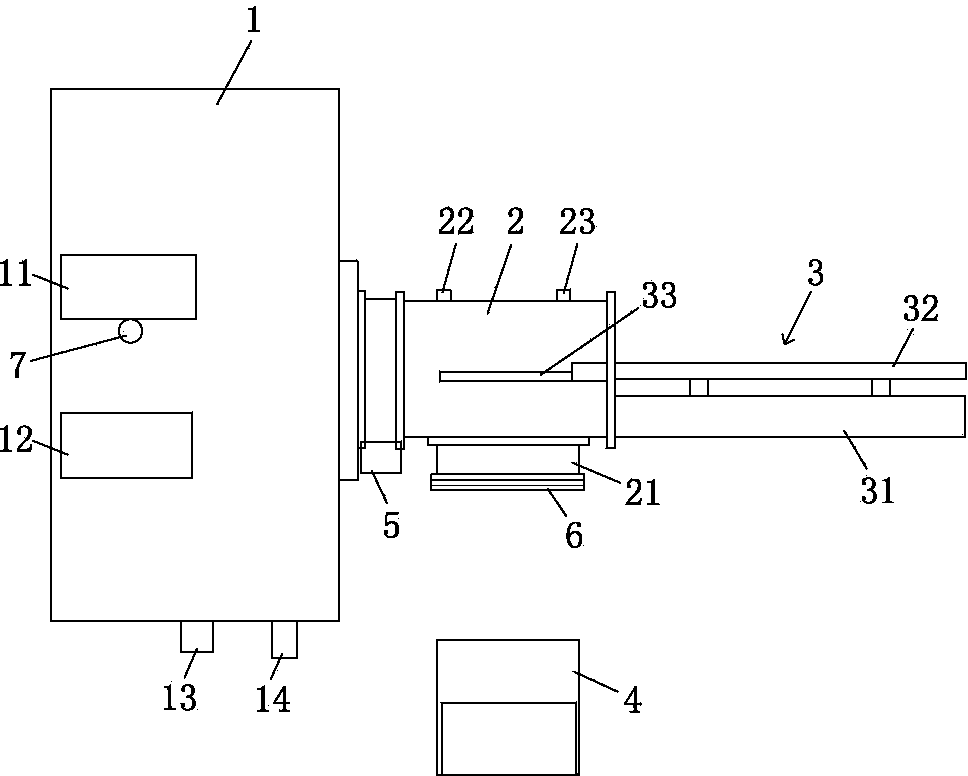

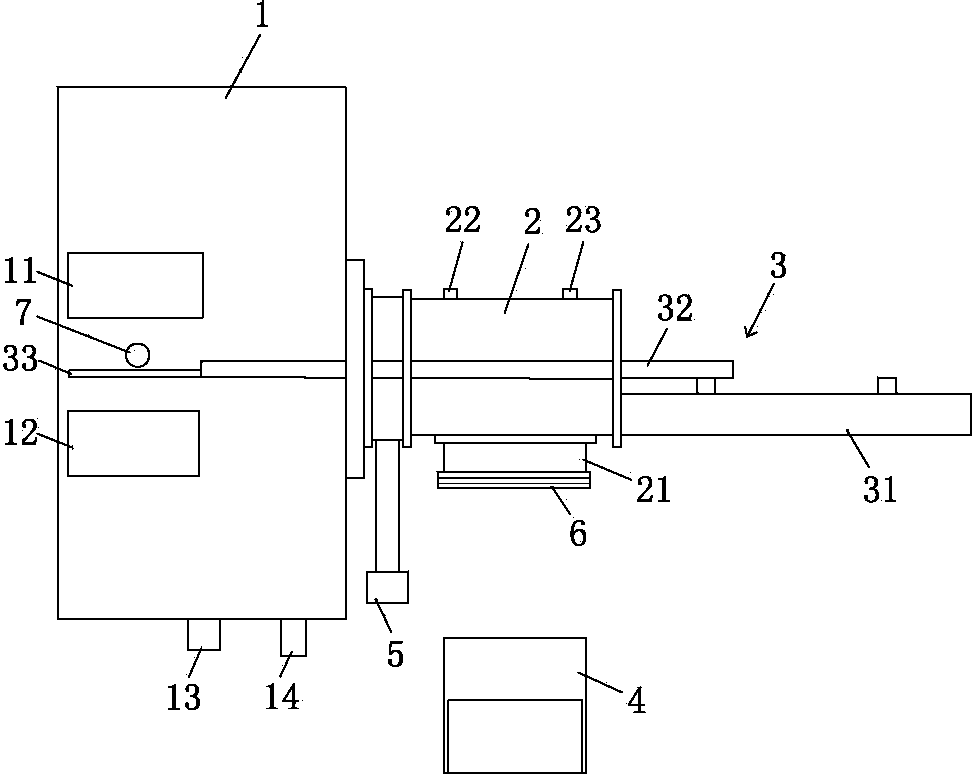

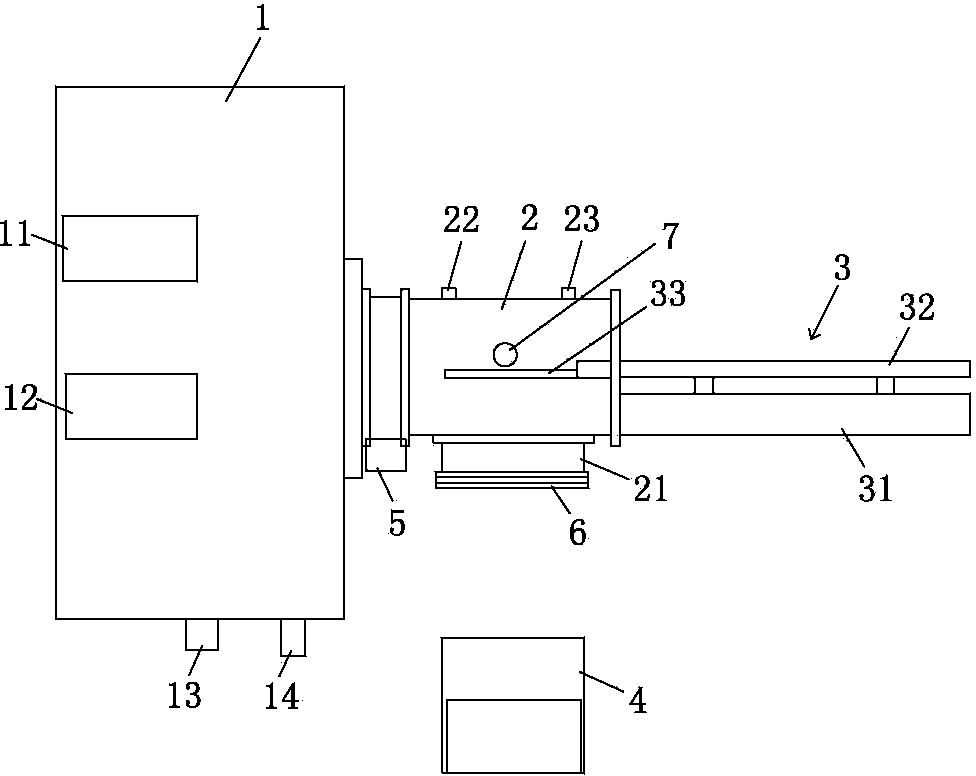

[0051] See Figure 1 to Figure 4 . The product take-out device of the vacuum die-casting machine of this embodiment includes a take-out chamber 2 communicated with the die-casting chamber 1, a take-out member 3 connected to the take-out chamber 2 and capable of moving back and forth between the die-casting chamber 1 and the take-out chamber 2, and a set The tank body below the extraction chamber 2 is filled with liquid; in this embodiment, the tank body filled with liquid is the water tank 4 . Wherein, the die-casting chamber 1 is provided with an upper mold 11 and a lower mold 12 for the die-cast product 7 .

[0052] Wherein, a first automatic door 5 is arranged between the die-casting chamber 1 and the take-out chamber 2; when the product 7 is die-cast, the first automatic door 5 is in a closed state, and when the product 7 is taken out after the die-cast product 7, the first automatic door 5 is opened , that is, the first automatic door 5 can move up and down so that it i...

Embodiment 2

[0060] The product taking-out method of the vacuum die-casting machine of the present embodiment, its product taking-out method is to utilize the product taking-out device of the vacuum die-casting machine of embodiment 1 (see Figure 1 to Figure 4 ) A method for taking out the injection-molded product 7, which includes the following steps:

[0061] Step 1, after the product is injection-molded, open the first automatic door 5 set between the die-casting chamber 1 and the take-out chamber 2;

[0062] Step 2, drive the moving plate 32 of the removal part 3 to drive the receiving plate 33 to pass through the first automatic door 5 and reach the die-casting chamber 1;

[0063] Step 3, after the receiving plate 33 receives the injection-molded product 7 from the die-casting chamber 1, the receiving plate 33 is driven by the moving plate 32 to return to the take-out chamber 2;

[0064] Step 4, close the first automatic door 5;

[0065] Step 5, open the first exhaust port 23 of th...

Embodiment 3

[0073] See Figure 1 to Figure 4 . The vacuum die-casting machine of this embodiment includes a die-casting chamber 1 and a product take-out device of the vacuum die-casting machine of Embodiment 1; the die-casting chamber 1 communicates with the take-out chamber 2 of the product take-out device of the vacuum die-casting machine of Embodiment 1.

[0074] The vacuum die-casting machine of this embodiment, since the amorphous alloy product after die-casting is taken out by the product take-out device of the vacuum die-casting machine of embodiment 1, therefore, has the advantages of simple structure and small volume, not only can improve the good product rate of the product, Therefore, the production performance is improved, and the production process time can be shortened, thereby shortening the entire production cycle of the amorphous alloy product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com