Fore-and-aft movement lifting mechanism of full-automatic screw locking machine

A technology that moves back and forth and locks the screw machine. It is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of damage to the screw hole of the workpiece, screw damage, and the inability to ensure the accuracy of the screw, and achieve the effect of preventing scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be more clearly defined.

[0008] See figure 1 , The embodiment of the present invention includes:

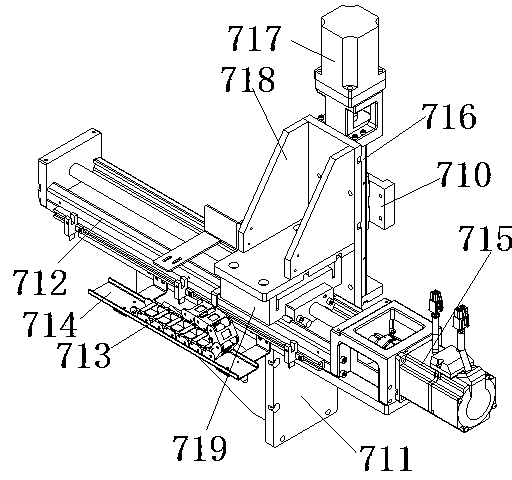

[0009] A forward and backward moving lifting mechanism of a fully automatic screw locking machine. The forward and backward moving lifting mechanism of the fully automatic screw locking machine includes a lifting slide 710, a ribbed triangular base plate 711, a front and rear single-axis servo drive slide 712, a cable drag chain 713, and a cable Drag chain slot plate 714, forward and backward moving motor 715, lifting single-axis servo-driven slide rail 716, lifting motor 717, and rib triangular connecting plate 718. The front and rear single-axis servo-driven slide rail ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap