A multi-station continuous processing machine tool for valve body and valve plate

A processing machine tool and multi-station technology, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long waiting time, single movement of workpieces, and many idle stations, so as to save time and labor costs, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

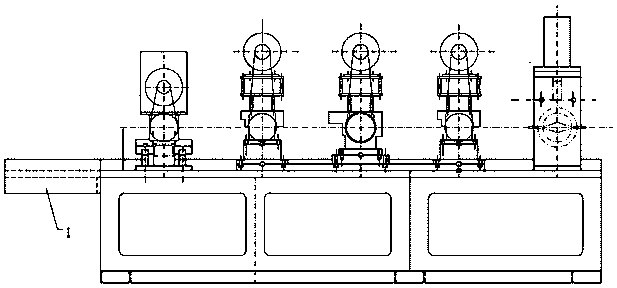

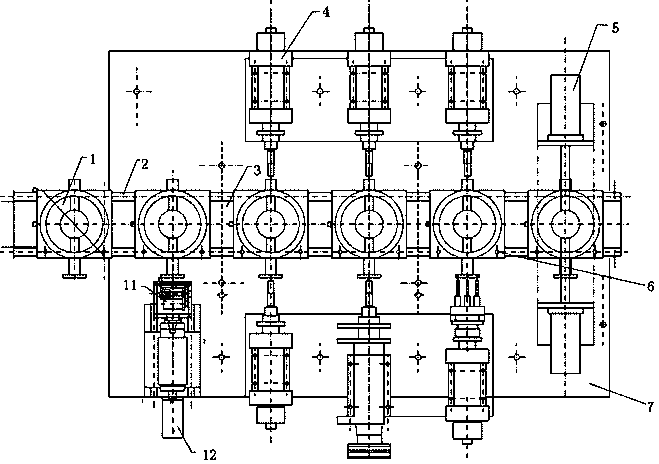

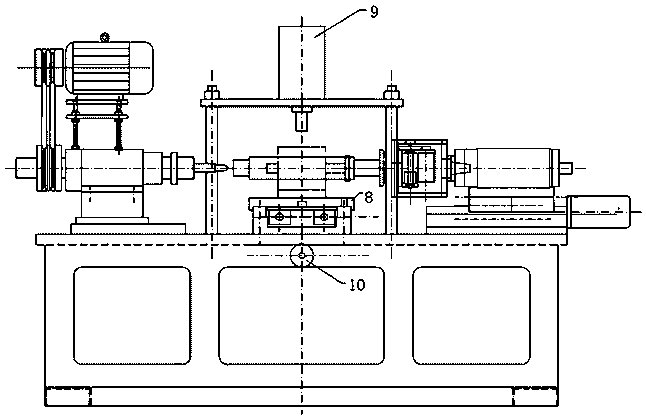

[0024] Such as Figure 1 to Figure 3 As shown, a valve body and valve plate multi-station continuous processing machine tool according to the present invention includes: guide rail 2, feeding plate 3, workbench 7 and movable tooling base 8, and 6 movable tooling bases 8 are sequentially installed on On the workbench 7 , the guide rail 2 and the feeding plate 3 are used to move the workpiece 1 between the movable tooling bases 8 . Among them, the 6 movable tooling bases are in turn: the feeding tooling base, which is used to send the workpiece 1 into the processing machine tool; the boring head boring flange end face, and the sub-mouth tooling base, which can One-time completion; two-way drilling and reaming tooling base; two-way scribing and sinking step hole tooling base, using a special compound tool for two-way scribing and sinking step holes; multi-hole drilling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com