Semi-finished product forming structure applicable to handkerchief paper packaging machine

A technology for forming structures and semi-finished products, which is applied to the types of packaging items, paper product packaging, packaging, etc. It can solve problems such as low packaging efficiency, offset patterns or patterns, and dislocation of semi-finished products, so as to improve packaging efficiency and accuracy. The effect of saving packaging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

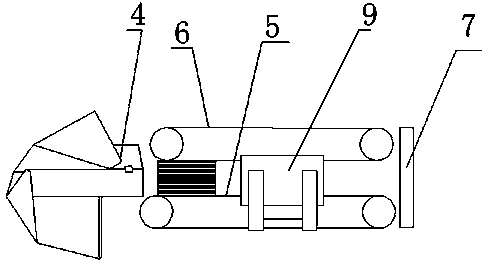

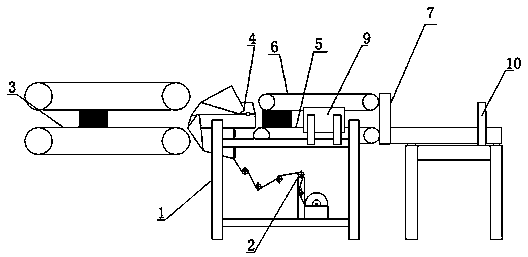

[0044] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention includes

[0045] Packaging film forming device 4: used to wrap the packaging film on the material to form a columnar packaging bag with one side open;

[0046] The first conveying mechanism 5: located at the discharge end of the packaging film forming device 4, and used to convey the columnar packaging bag;

[0047] Heat-sealing mechanism 9: installed above or on the side of the first conveying mechanism 5, for heat-sealing the side opening of the columnar packaging bag;

[0048] Cutting mechanism 7: installed at the rear end of the first conveying mechanism 5, used for cutting and dividing the heat-sealed columnar packaging bag to form a single semi-finished packaging bag with both ends open.

[0049] In the present invention, the continuously or intermittently input packaging film wraps the continuously or intermittently conveyed materials to form a c...

Embodiment 2

[0051] As another preferred embodiment of the present invention, with reference to the attached figure 1 , the present invention includes

[0052] Packaging film forming device 4: used to wrap the packaging film on the material to form a columnar packaging bag with one side open;

[0053] The first conveying mechanism 5: located at the discharge end of the packaging film forming device 4, and used to convey the columnar packaging bag;

[0054] Heat-sealing mechanism 9: installed above or on the side of the first conveying mechanism 5, for heat-sealing the side opening of the columnar packaging bag;

[0055] Cutting mechanism 7: installed at the rear end of the first conveying mechanism 5, used for cutting and dividing the heat-sealed columnar packaging bag to form a single semi-finished packaging bag with both ends open.

[0056] In the present invention, the continuously or intermittently input packaging film wraps the continuously or intermittently conveyed materials to fo...

Embodiment 3

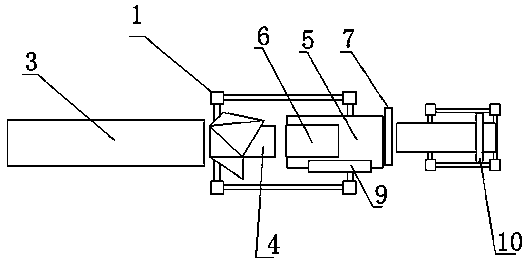

[0059] As another preferred embodiment of the present invention, with reference to the attached figure 1 , 4 and 6, the present invention includes

[0060] Packaging film forming device 4: used to wrap the packaging film on the material to form a columnar packaging bag with one side open;

[0061] The first conveying mechanism 5: located at the discharge end of the packaging film forming device 4, and used to convey the columnar packaging bag;

[0062] Heat-sealing mechanism 9: installed above or on the side of the first conveying mechanism 5, for heat-sealing the side opening of the columnar packaging bag;

[0063] Cutting mechanism 7: installed at the rear end of the first conveying mechanism 5, used for cutting and dividing the heat-sealed columnar packaging bag to form a single semi-finished packaging bag with both ends open.

[0064] In the present invention, the continuously or intermittently input packaging film wraps the continuously or intermittently conveyed mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com