Machine tool for firing multicore laser tube completely made of glass

A laser tube, all-glass technology, applied in the field of machine tools, can solve problems such as difficulty in manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

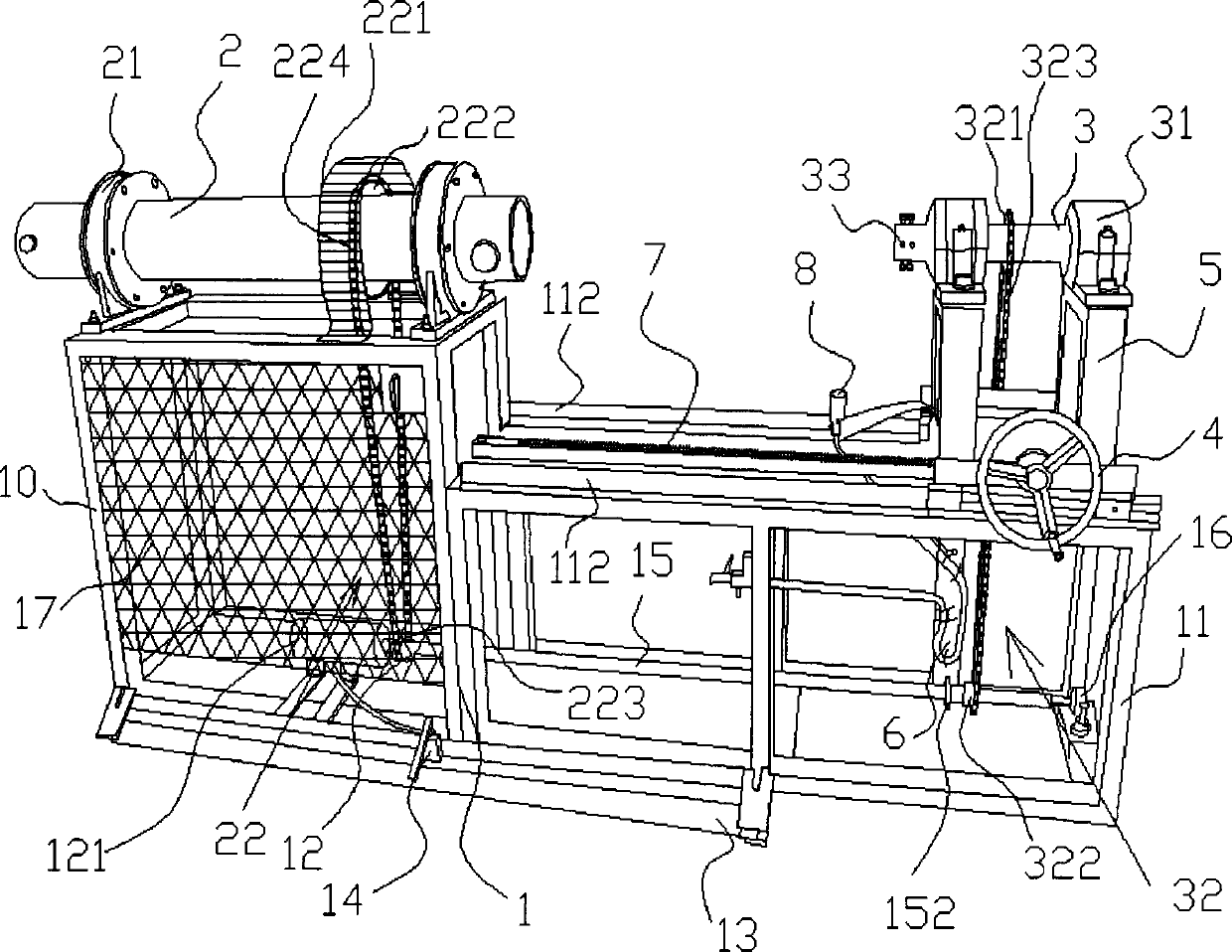

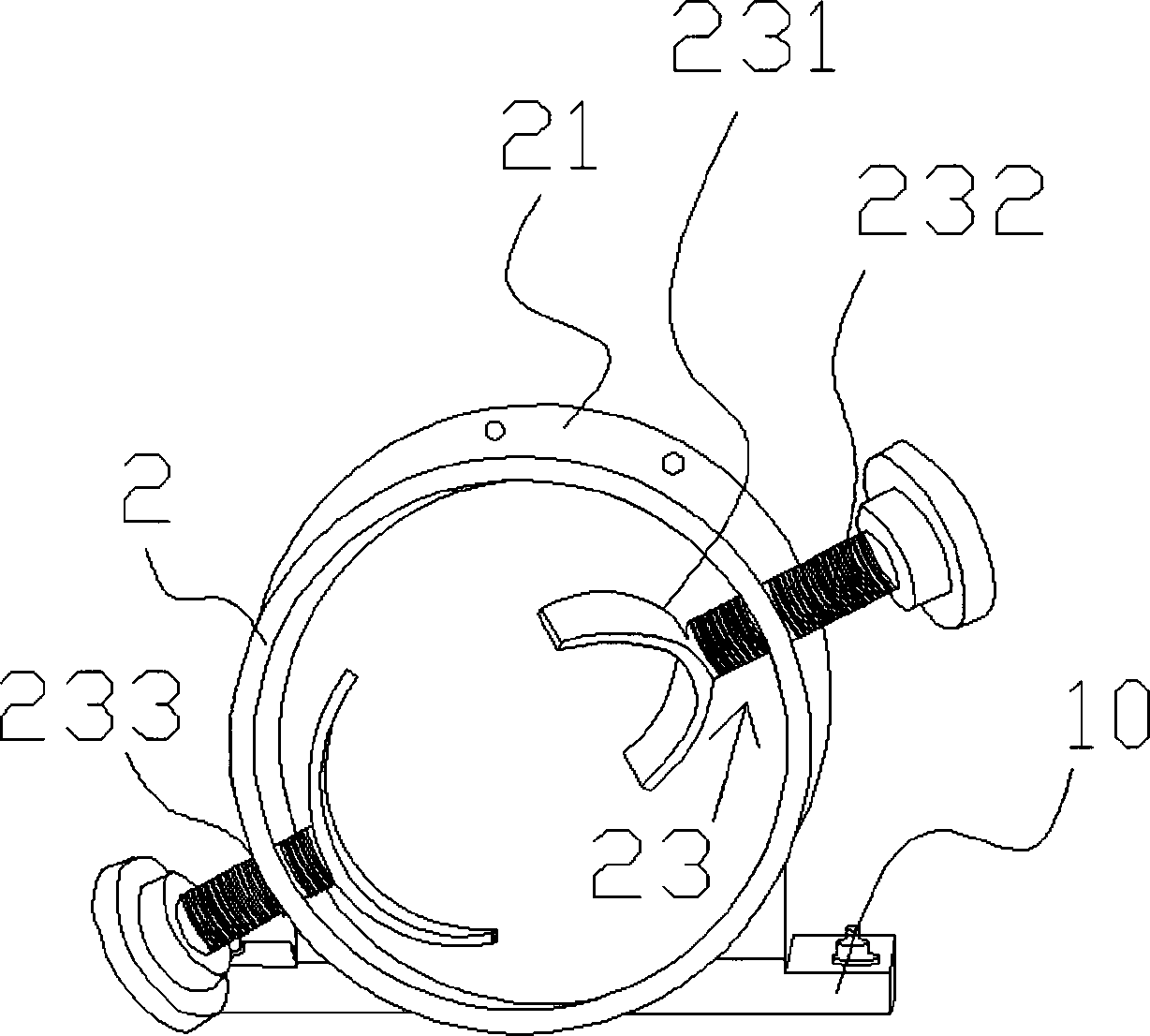

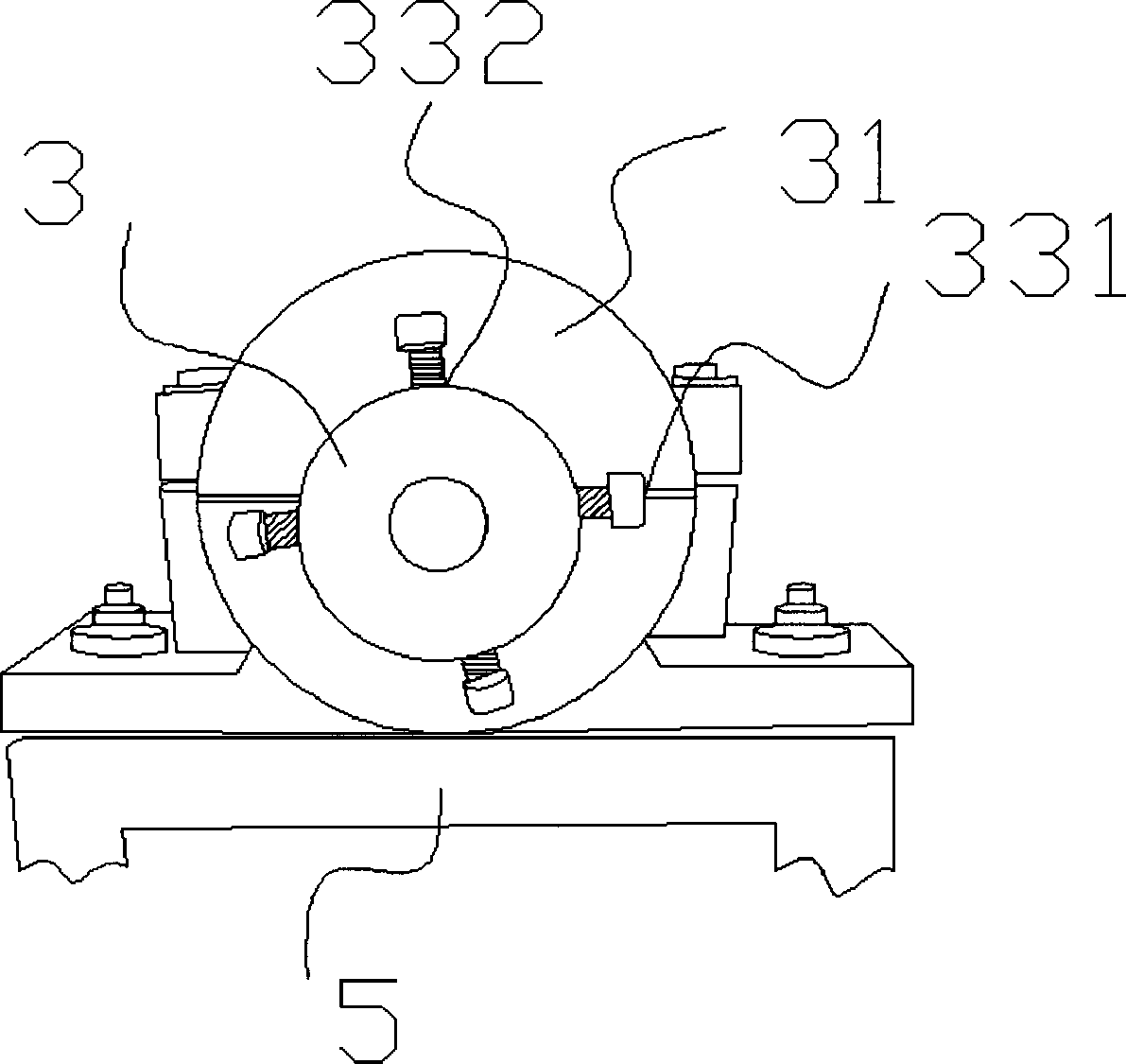

[0036] Such as figure 1 As shown, the present invention provides a kind of lathe that is used for all-glass one-tube multi-core laser tube burning, comprises base part 1, first positioner 2, second positioner 3, driving device 12, sliding track 112 and flame shower head 8;

[0037] Both the first positioner 2 and the second positioner 3 are disposed on the base part 1 . The base part 1 is used to fix the first locator 2 and the second locator 3 and play a role of supporting the first locator 2 and the second locator 3 . In this embodiment, the base part 1 may include a first base part 10 and a second base part 11, the first base part 10 is slightly higher than the second base part 11, and both the first base part 10 and the second base part 11 It is a rectangular parallelepiped frame made of a plurality of iron prisms welded to each other. The first base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com