Heat exchanger for an energy storage device

一种能量储存、热交换器的技术,应用在热交换设备、电化学发生器、照明和加热设备等方向,能够解决设置在能量储存电池之间、能量储存电池损耗热大、能量储存器体积增大等问题,达到能够设置紧密、减少零件数量、结构紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

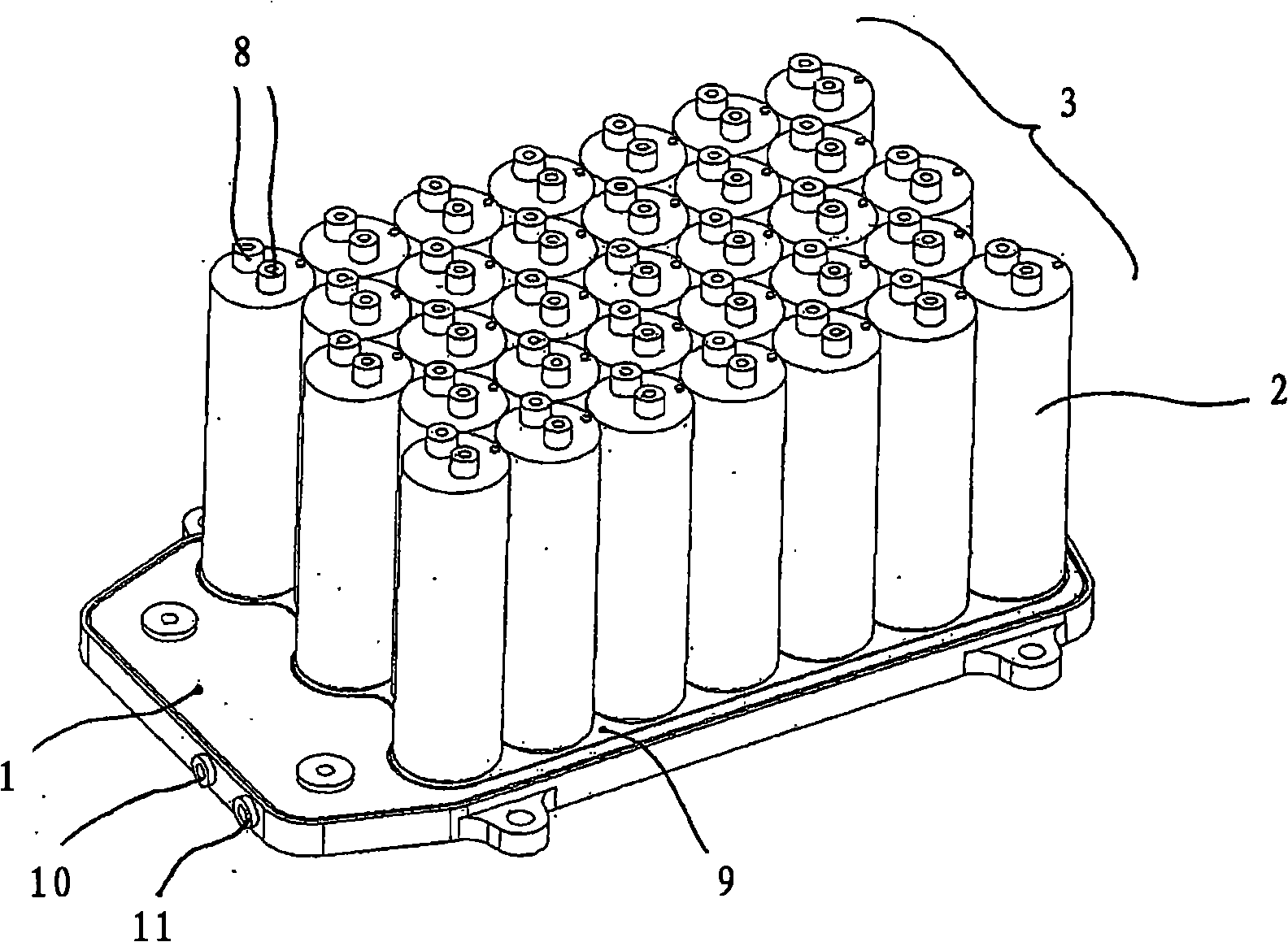

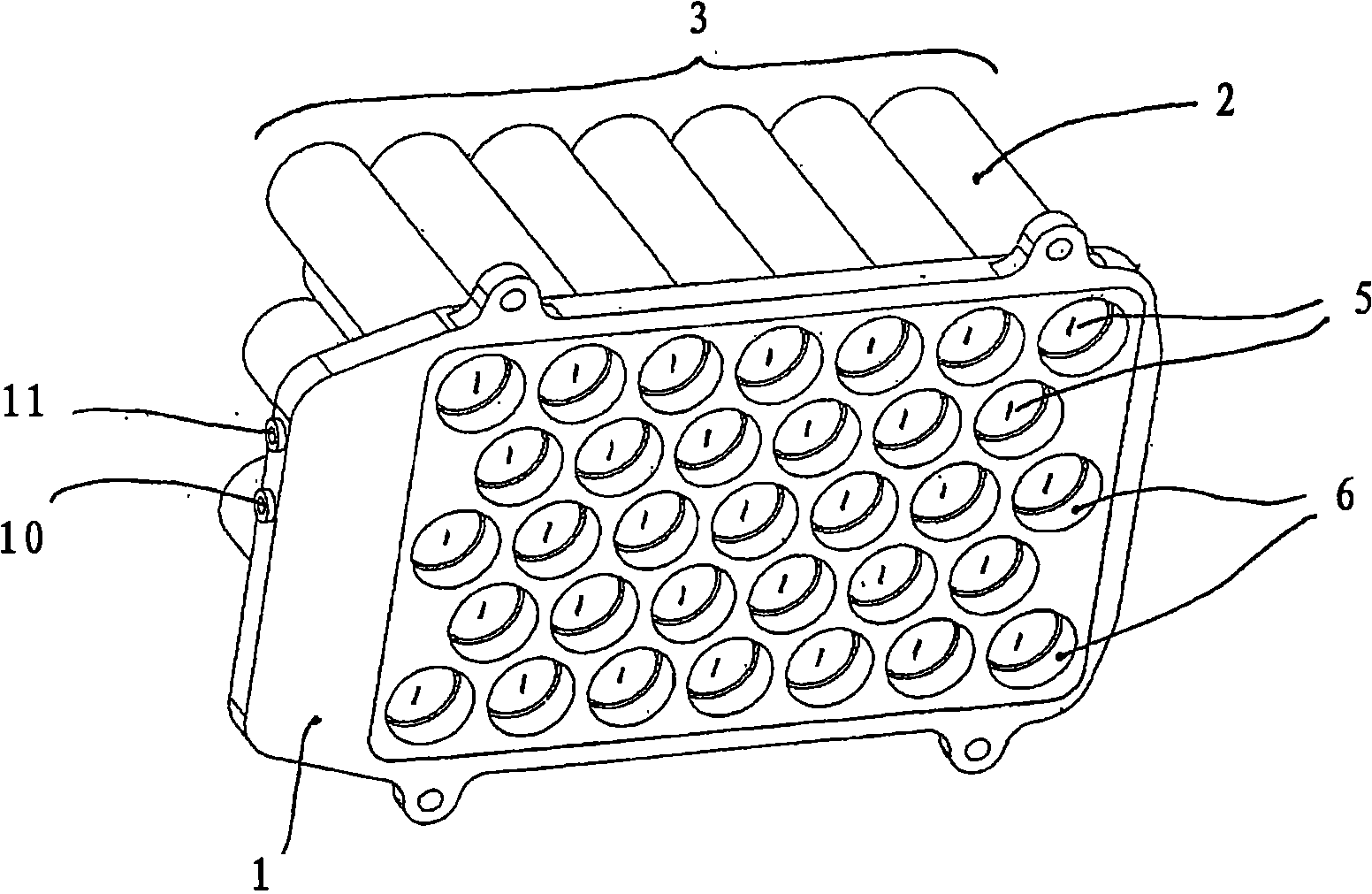

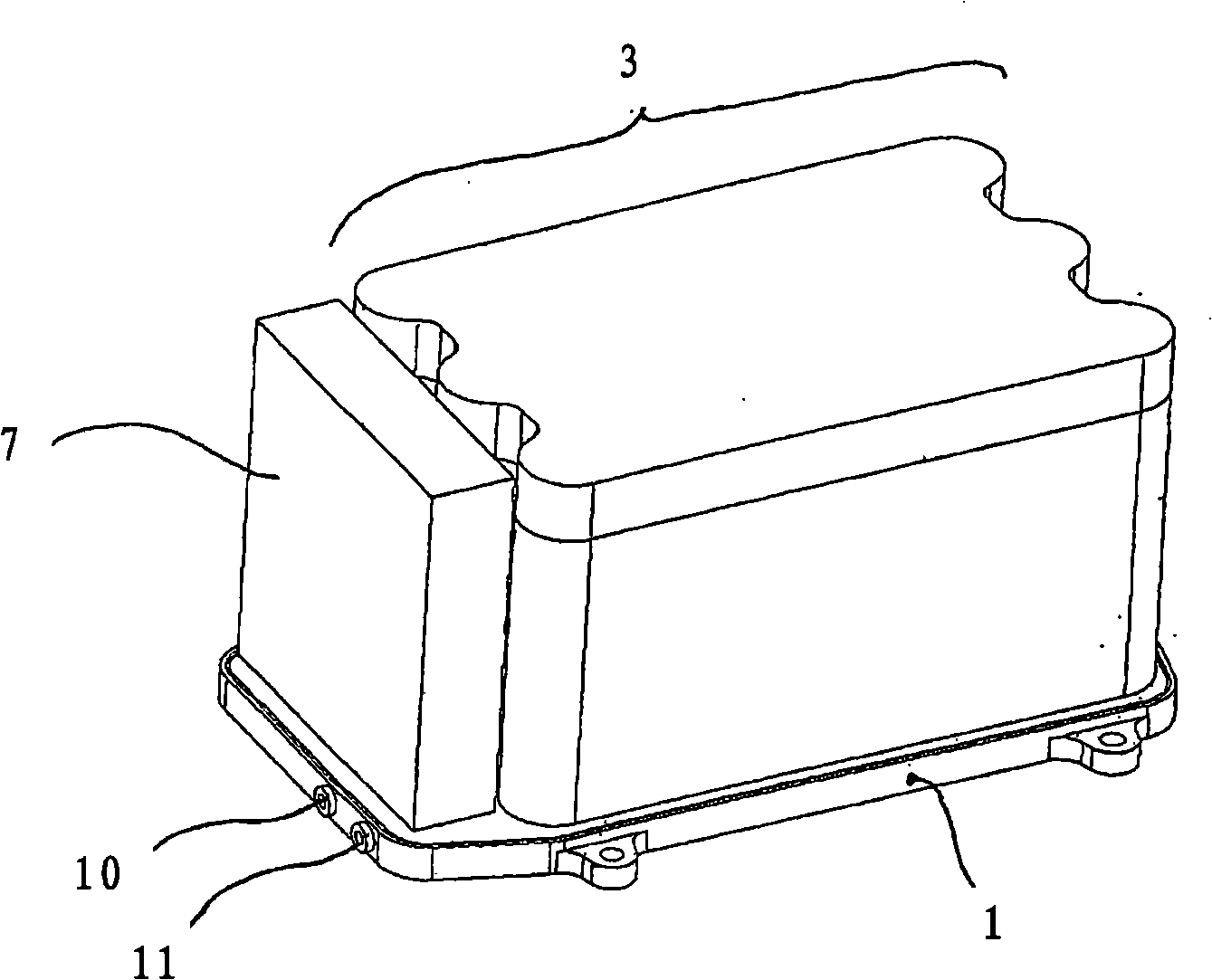

[0023] figure 1 Shown is the arrangement of an energy storage battery 2 on a heat exchanger 1 according to the invention. The energy storage battery 2 is attached to the heat exchanger 1 and is thermally connected to it. The energy storage battery is fixed on the side away from the electrode 8, and this side has a safety pressure relief hole 5 (such as figure 2 shown). To facilitate the fixing of the energy storage battery, the heat exchanger 1 may have recesses 9 into which the energy storage battery 2 may be inserted. The energy storage battery 2 can be at least partially inserted into figure 2 through holes shown. The energy storage cells 2 can be arranged very close to each other, since a heat exchanger between them can be dispensed with.

[0024] The heat exchanger 1 has an inlet opening 10 and an outlet opening 11 for the inlet and outlet of cooling fluid, which removes the heat transferred from the energy storage battery 2 into the heat exchanger 1 .

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com