Biomass cooking heating furnace

A biomass, heating stove technology, applied in the direction of household stoves/stoves, lighting and heating equipment, sustainable buildings, etc., can solve the problems of must use pellet fuel, must use fans, must be used outdoors, etc., to prolong the stay time , the effect of rapid fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings.

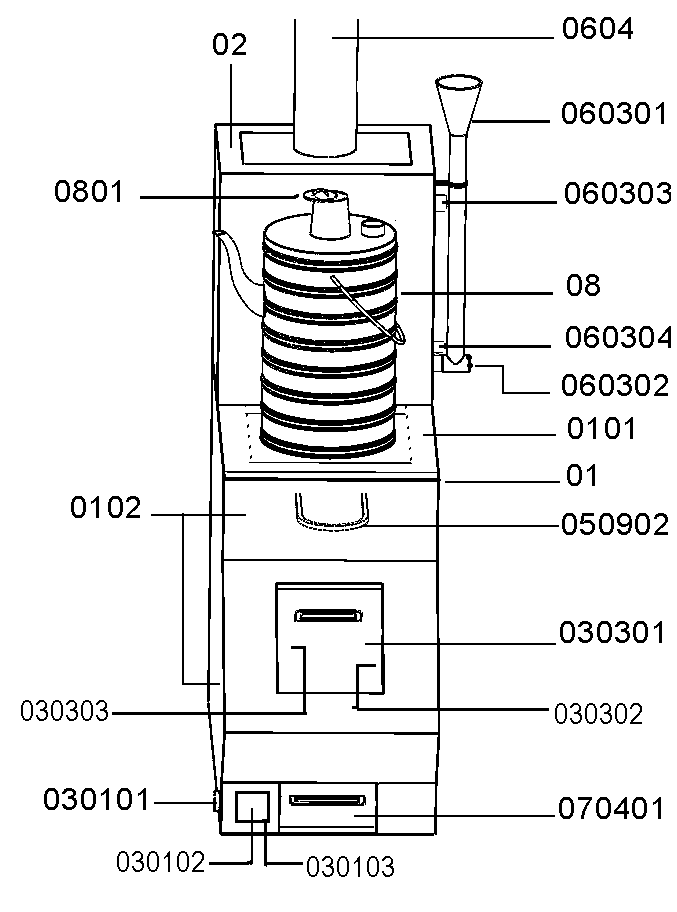

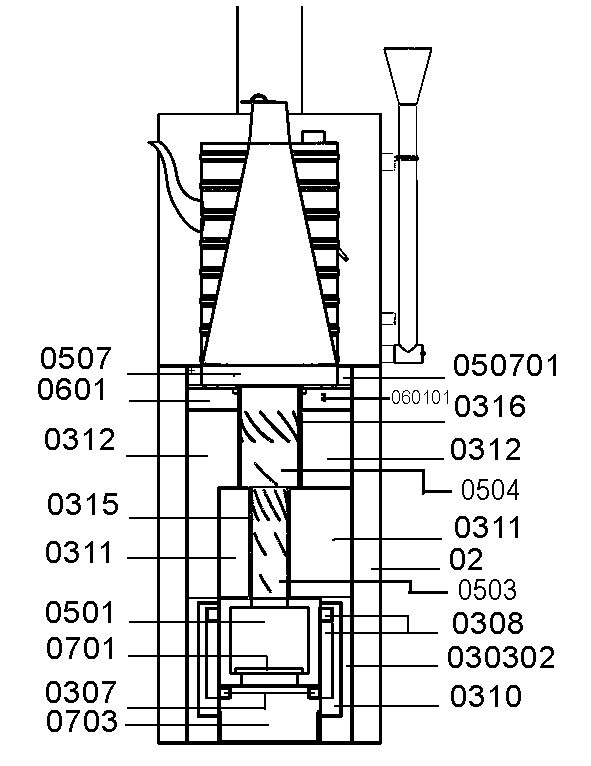

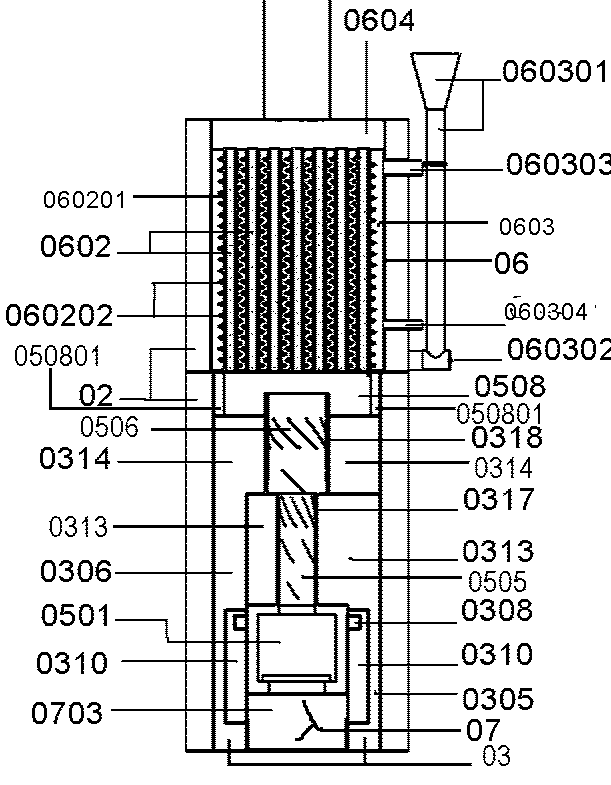

[0047] Such as Figure 1 to Figure 10 The biomass cooking and heating stove shown, in the figure:

[0048] 01-furnace body, 0101-table top, 0102-furnace shell, 0103-bottom plate,

[0049] 02-Insulation layer,

[0050]03 Oxygen supply mechanism, 0301 Oxygen supply chamber 1, 030101 Forced blast inlet, 030102 Natural wind inlet, 030103 Natural wind volume adjustment switch, 0302 Oxygen supply chamber 2, 0303 Oxygen supply chamber 3, 030301 Oxygen supply chamber 3 outer cover, 030302 Air preheating passage 1 entrance, 030303 air preheating passage 2 entrance, 0304 special passage between oxygen supply chamber 2 and oxygen supply chamber 3, 0305 air preheating passage 1, 0306 air preheating passage 2, 0307 furnace secondary distribution Air-limited oxygen maintenance channel, 0308 furnace secondary air distribution air-limited oxygen maintenance chamber, 0309 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com