A Substrate Movement Method for Improving Thickness Uniformity of Magnetron Sputtering Rectangular Target

A magnetron sputtering, rectangular target technology, applied in sputtering coating, ion implantation coating, metal material coating process and other directions, can solve the problem of uneven film thickness, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

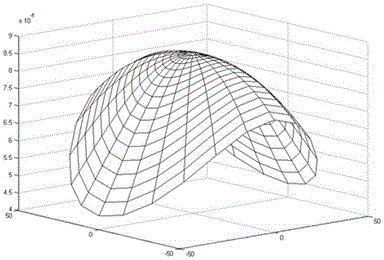

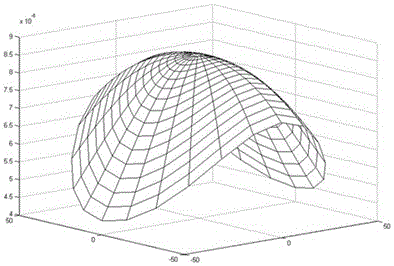

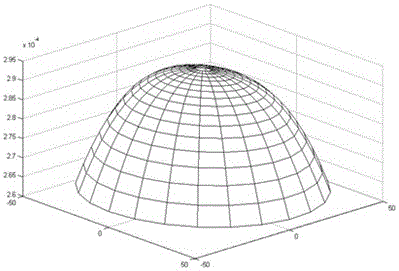

Image

Examples

Embodiment 2

[0035] In embodiment two, compared with embodiment one, only the spacing D of reciprocating scanning is changed, and the 120mm of embodiment one is increased to 140mm, and the eccentric rotation time compensated with it is shortened to 12s. In Example 2, the film thickness non-uniformity is close to 3%.

[0036] When using the magnetron sputtering method to sputter the substrate, it can specifically be DC magnetron sputtering, radio frequency magnetron sputtering, intermediate frequency magnetron sputtering, and pulse magnetron sputtering. Let me go into more detail.

[0037] Therefore, by adopting the technical solution of the embodiment of the present invention, not only is it simple and easy to implement, but also for a rectangular target, the non-uniformity of the film thickness on the entire circular substrate with a diameter of 100mm can be controlled within 3%-4%, and a large Film thickness uniformity across the area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com