A tension and compression testing machine

A testing machine, push-pull cylinder technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as recording errors and work losses, and achieve the effect of preventing lateral collapse, avoiding injury, and expanding the test range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

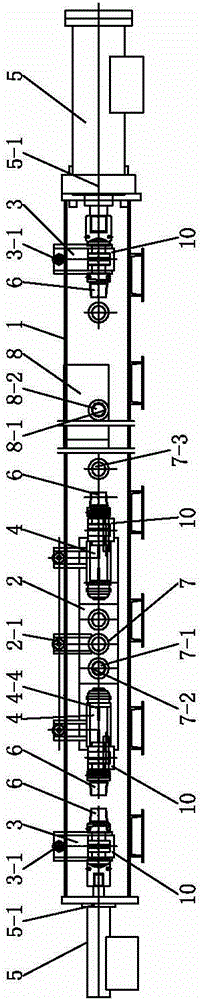

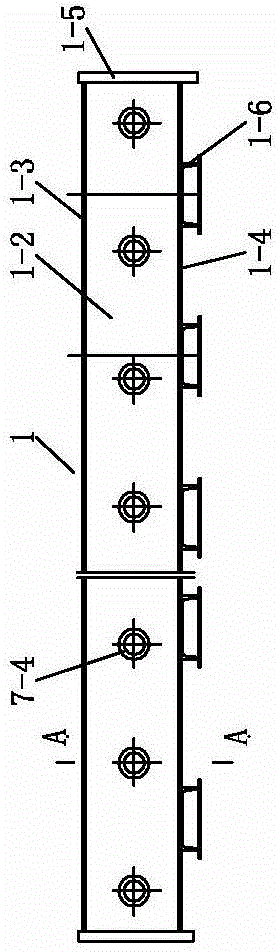

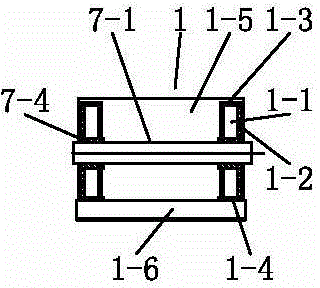

[0040] Such as figure 1 As shown, a tensile and compression testing machine provided in this embodiment includes a main frame body 1, a mobile carrier 2, a cylinder head 3, a connecting device 4 and a push-pull cylinder 5, and the mobile carrier 2 is a mobile The mobile two-way carrying vehicle, the mobile two-way carrying vehicle 2 is located in the middle of the carrying main frame body 1 and moves back and forth along the length direction of the carrying main frame body 1 through the positioning device 7 to be positioned with the carrying main frame body 1 Fixedly connected, there are two connecting devices 4, and the two connecting devices 4 are respectively arranged on the two ends of the mobile two-way carrying vehicle 2, there are two cylinder head vehicles 3, and the push-pull oil cylinder 5 also has two Two, the two cylinder heads 3 are respectively connected to the two ends of the bearing main frame 1 through the two oil cylinders 5, and the joint 6 on the cylinder h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com