Method for simultaneously determining Zr, Cu and Ni contents in Zr-Cu-Ni-Al amorphous alloy

A zr-cu-ni-al, amorphous alloy technology, applied in the field of chemical analysis, can solve the problems of no joint determination technology patents and reports, not suitable for nickel-containing material determination, long measurement period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

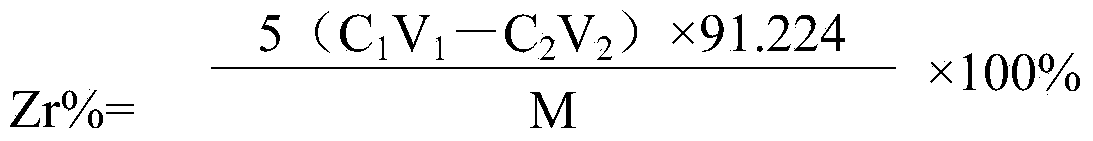

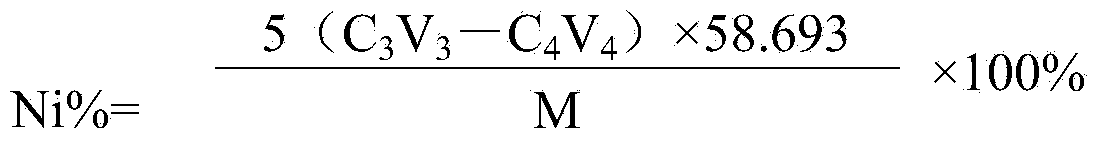

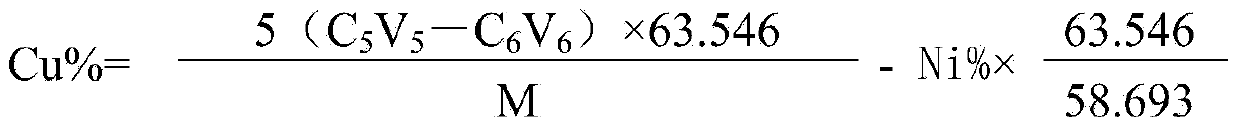

Image

Examples

Embodiment 1

[0038] This embodiment is a method for jointly determining the contents of Zr, Cu, and Ni in Zr55Cu30Al10Ni5.

[0039] Step 1: Zr-Cu-Ni-Al amorphous alloy sample weighing: Weigh 0.2994g of Zr-Cu-Ni-Al amorphous alloy sample, accurate to 0.0001g, and place it in a 250mL beaker. An accurately weighed Zr-Cu-Ni-Al amorphous alloy sample is obtained.

[0040] Step 2: Zr-Cu-Ni-Al amorphous alloy sample dissolves and smokes: Add 10mL of Zr-Cu-Ni-Al amorphous alloy sample with a density of 1.84g / mL in turn to a beaker containing accurately weighed sulfuric acid and 2g of solid ammonium sulfate, place the beaker on an electric stove and heat until the solution in the beaker is clear, continue heating until the solution emits white smoke, then add 2mL of nitric acid with a density of 1.42g / mL, continue heating the beaker until the solution emits white smoke, The beaker was removed from the electric furnace, and cooled naturally to room temperature to obtain a Zr-Cu-Ni-Al amorphous allo...

Embodiment 2

[0058] This embodiment is a method for jointly determining the contents of Zr, Cu and Ni in Zr67Cu26Al4Ni3.

[0059] Step 1: Zr-Cu-Ni-Al amorphous alloy sample weighing: Weigh 0.3002g Zr-Cu-Ni-Al amorphous alloy sample, accurate to 0.0001g, and place it in a 250mL beaker. An accurately weighed Zr-Cu-Ni-Al amorphous alloy sample is obtained.

[0060] Step 2: Zr-Cu-Ni-Al amorphous alloy sample dissolves and smokes: Add 10mL of Zr-Cu-Ni-Al amorphous alloy sample with a density of 1.84g / mL in turn to a beaker containing accurately weighed sulfuric acid and 2g of solid ammonium sulfate, place the beaker on an electric stove and heat until the solution in the beaker is clear, continue heating until the solution emits white smoke, then add 2mL of nitric acid with a density of 1.42g / mL, continue heating the beaker until the solution emits white smoke, The beaker was removed from the electric furnace, and cooled naturally to room temperature to obtain a Zr-Cu-Ni-Al amorphous alloy sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com