A kind of array substrate and its preparation method, display device

An array substrate and peripheral technology, applied in optics, instruments, electrical components, etc., can solve the problem of reducing the aperture ratio of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

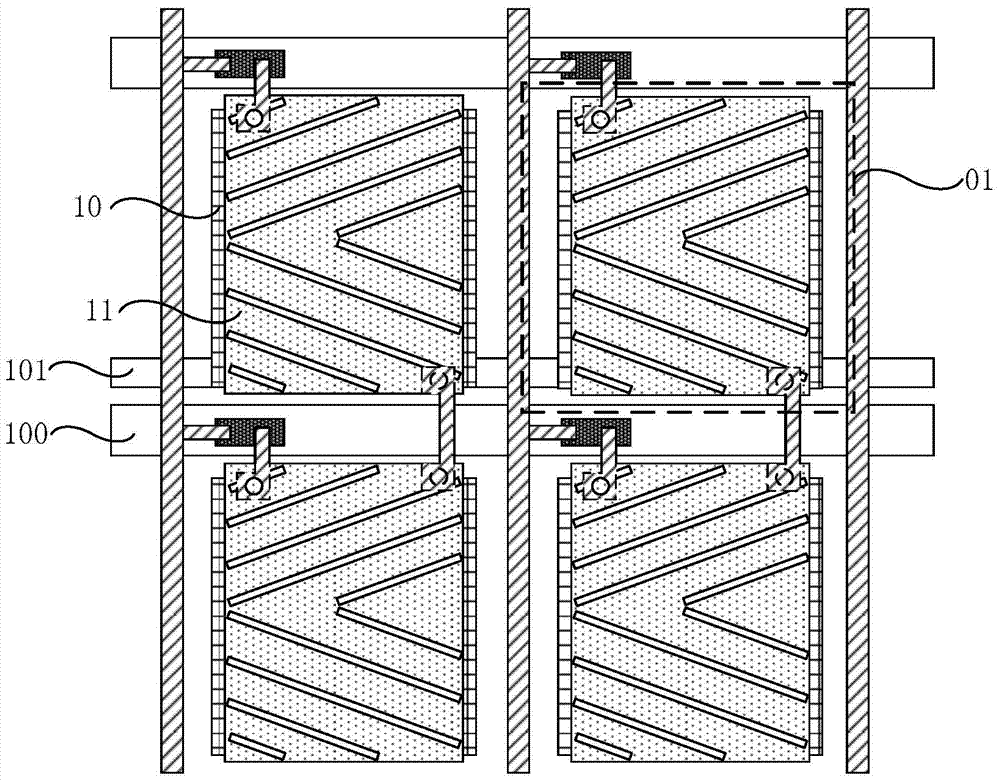

Embodiment 1

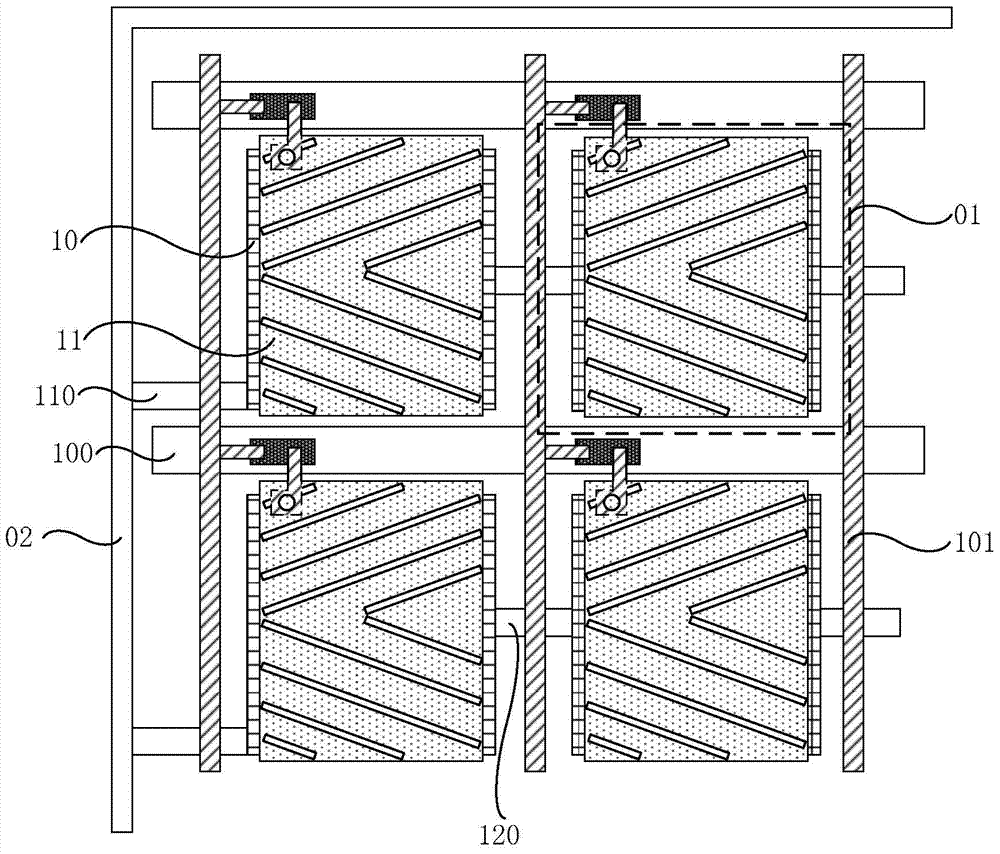

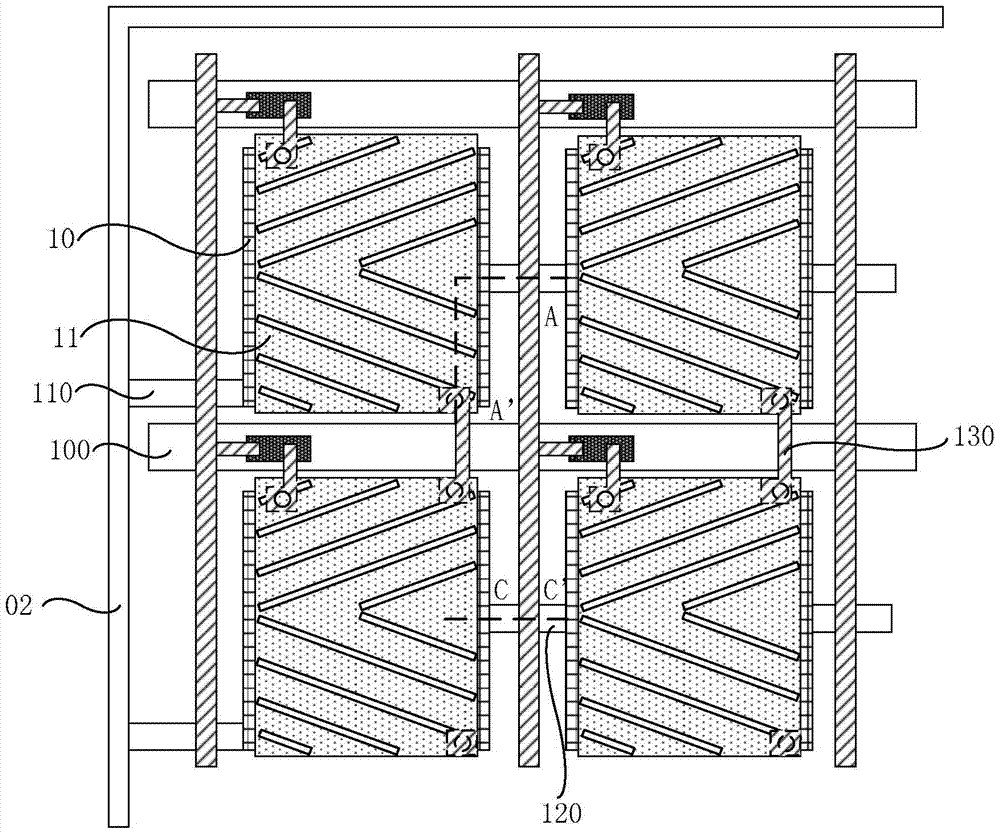

[0054] Such as Figure 3a As shown, the array substrate may further include a plurality of third connection portions 130, arranged between two adjacent pixel units 01 along the second direction, for electrically connecting the common electrodes 10 of the two adjacent pixel units 01 .

[0055] Specifically, the above-mentioned third connecting portion 130 may be made of a transparent conductive material. When the third connection part 130 is made of a transparent conductive material, a via hole (not shown) can be formed on the surface of the pixel electrode 11 at a position corresponding to the third connection part 130, and then a third connection made of a transparent conductive material can be made. The part 130 electrically connects the common electrodes 10 of two adjacent pixel units 01 through the above-mentioned via holes. However, the pixel electrode 11 is also made of transparent conductive material. Therefore, it is also necessary to form an insulating layer betwee...

Embodiment 2

[0064] Such as Figure 4aAs shown, on the basis of Embodiment 1, the array substrate may further include a plurality of fourth connecting parts 140, which are arranged on the peripheral common electrode line 02 and the pixels on the side close to the peripheral common electrode line 02 along the second direction. Between the common electrodes 10 of the unit 01 is used to electrically connect the peripheral common electrode line 02 to the common electrode 10 of the above-mentioned pixel unit 01 .

[0065] Like the third connecting portion 130 in the first embodiment, the fourth connecting portion 140 may also be made of transparent conductive material.

[0066] Alternatively, in order to improve the electrical conductivity of the fourth connecting portion 140, the fourth connecting portion 140 may also be made of a metal material.

[0067] Preferably, in the case where the array substrate includes data lines 101, such as Figure 4b ( Figure 4a sectional view along BB').

...

Embodiment 3

[0091] Such as Figure 7 shown, including:

[0092] S201, such as Figure 8a As shown, a common electrode layer 04 is formed on a base substrate 03 .

[0093] Specifically, the above-mentioned common electrode layer 04 may be made of a transparent conductive material, such as ITO. The common electrode layer 04 may be deposited on the surface of the base substrate 03 by using a magnetron sputtering method.

[0094] S202 , forming a gate metal layer 05 on the surface of the common electrode layer 04 .

[0095] Specifically, the aforementioned gate metal layer 05 may be formed on the surface of the common electrode layer 04 by coating or magnetron sputtering.

[0096] S203, such as Figure 8b shown (where, Figure 8b —8d is edge Figure 3a The cross-sectional view of CC' is described by taking the second connection part 120 as an example, and the manufacturing process of the first connection part 110 can be obtained in the same way), and a layer of photoresist is coated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com