Combined filling system for measured wind speed loss values of multiple neighboring wind motors in wind field

A technology for filling systems and wind turbines, applied in forecasting, instrumentation, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

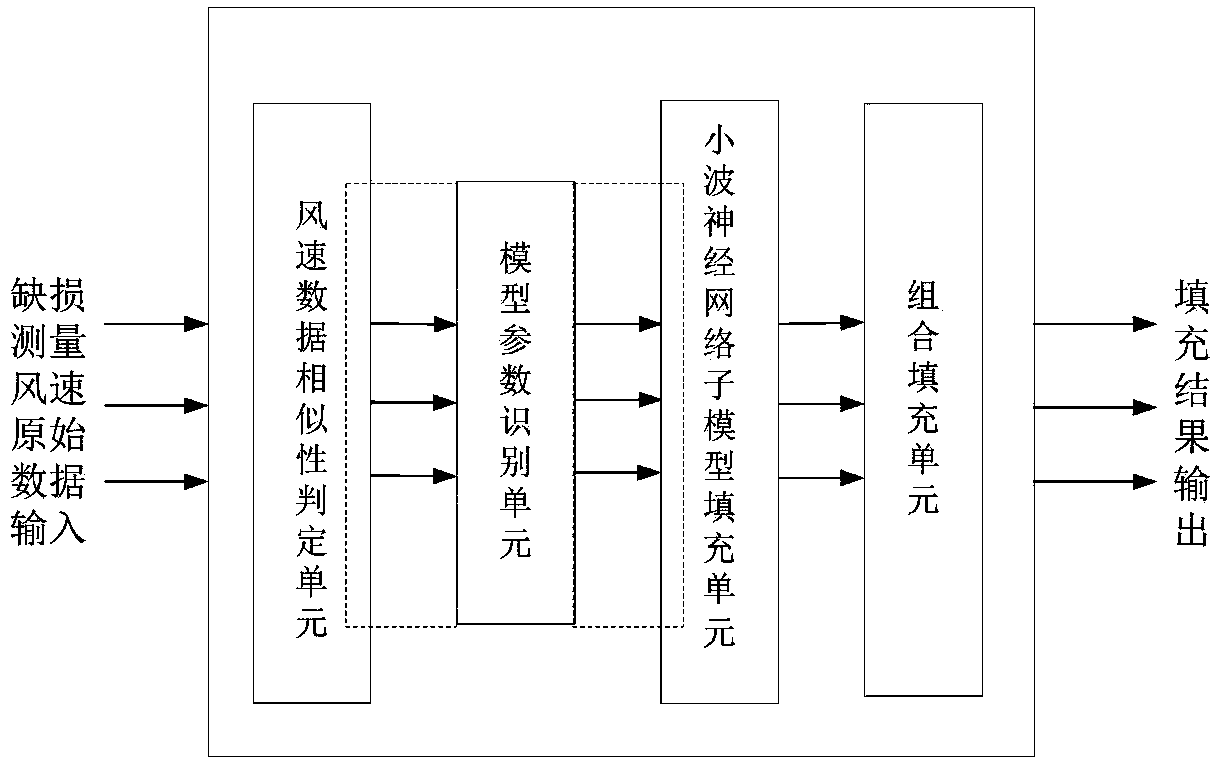

Method used

Image

Examples

example 1

[0127] Take Wind Turbine #WT 8 Combined filling in the defect measurement wind speed range [271~290] is taken as an example to illustrate the filling steps and effects of the defect value. Here, the start and end point of the defect value is T k =271, T l =290, the filling interval length is 20.

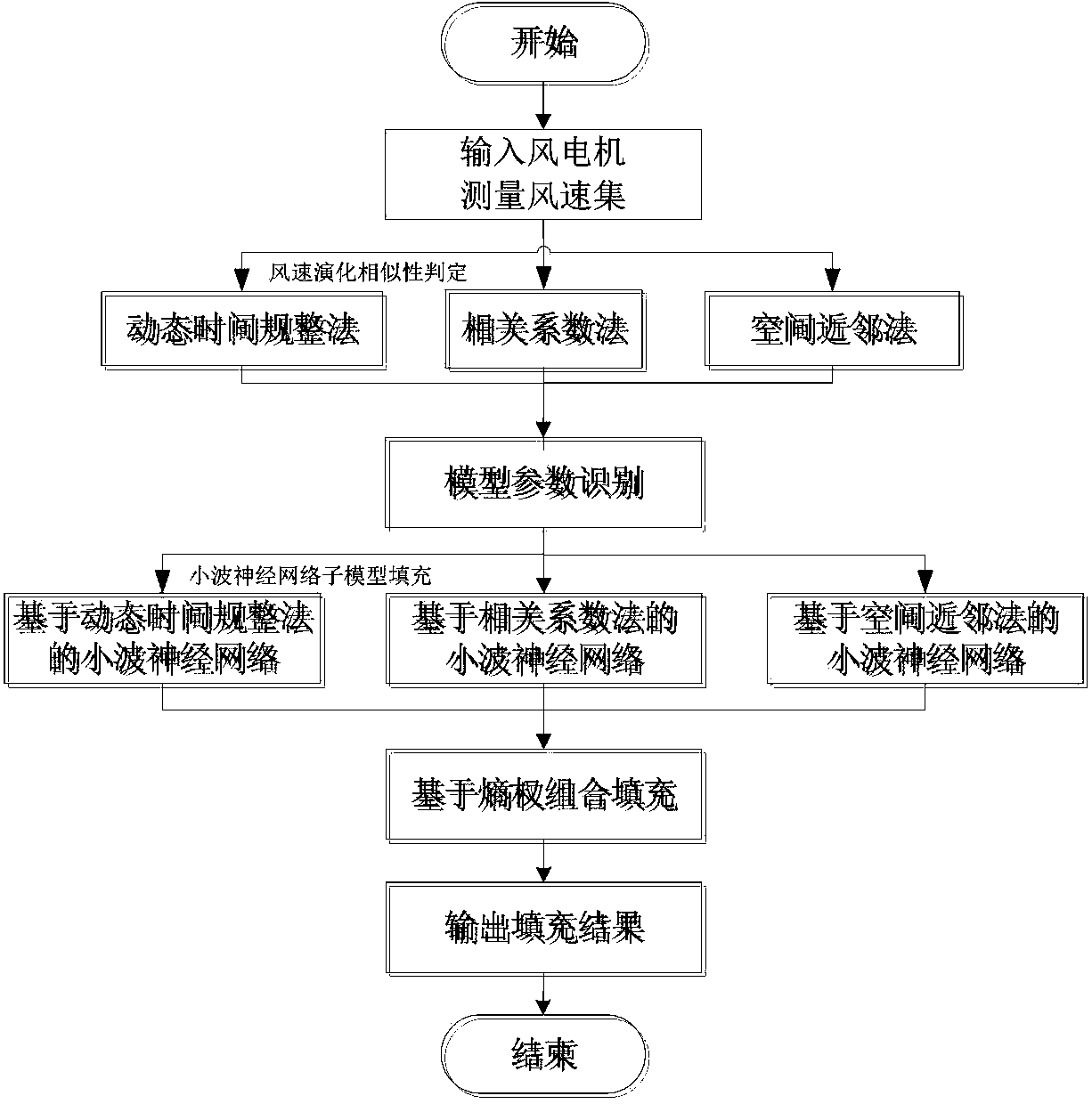

[0128] First of all, the wind speed data similarity determination unit adopts three methods including Dynamic Time Warping (DTW), correlation coefficient method, and spatial neighbor method, each from the inner interval of the wind field [T 271 ~T 290 ] Sampling wind speed data complete set of wind turbine #WT searches with wind turbine #WT 8 The wind speed evolution most similar to M 1 , M 2 , M 3 Typhoon motor:

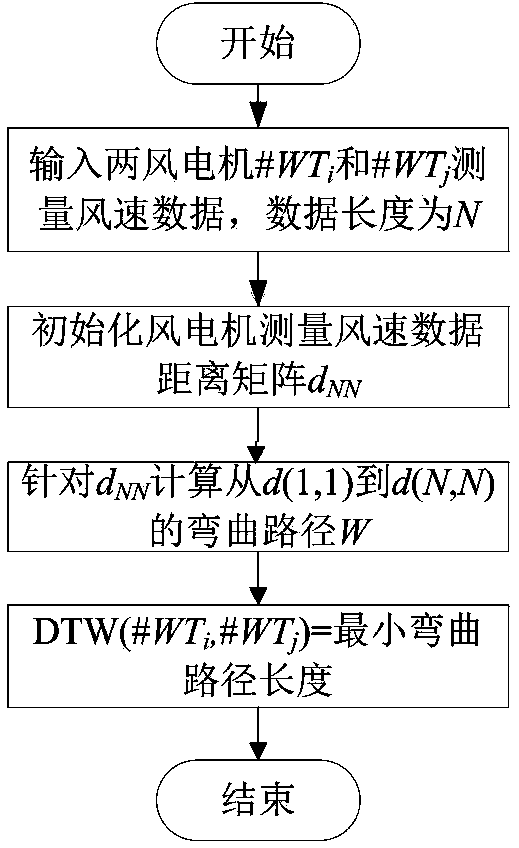

[0129] Calculation of Wind Turbine #WT by Dynamic Time Warping 8 The sampling interval [T 271-Len ~T 270 ] The DTW distance of the wind speed data, take the front M with the smallest DTW distance 1 Typhoon motor;

[0130] Correlation coefficient method to calcu...

example 2

[0151] In order to verify the universality of this application, for the 274 wind turbines in the wind field, each wind turbine starts with the 650th sampling point, and every hour, a total of 6 defect measurement wind speed starting points T are simulated. k ={650, 656, 662, 668, 674, 680}, the missing value filling experiment with the missing value interval length Lmiss=20 is carried out at each test point, and the effect of each method is measured by the error square sum SSE.

[0152] According to this method, all 274 wind turbines #WT in the wind farm 1 to #WT 274 , the starting point T of wind speed measurement for 6 defects k ={650, 656, 662, 668, 674, 680} Carry out the simulation according to the above steps. On the whole, when N=4, L=9, the generalization ability of each wavelet neural network sub-model is optimal. Moreover, based on the wavelet neural network established by the dynamic time warping method and the spatial neighbor method, the SSE decreases rapidly wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com