Design and detection method of camera calibration board

A technology of camera calibration and detection method, applied in the directions of calculation, image analysis, image data processing, etc., can solve the problems of inability to capture calibration plate images, small imaging, affecting the accuracy of corresponding points, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

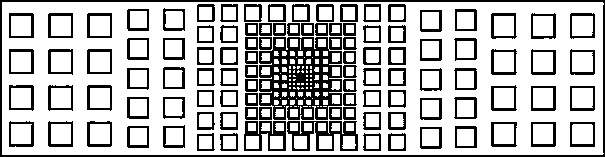

[0053] A design and detection method of a camera calibration board, comprising the following steps (such as Image 6 shown):

[0054] S1: The overall layout and design of the calibration board;

[0055] S2: measure and save the calibration plate information;

[0056] S3: Camera calibration.

[0057] Further, the step S1 specifically includes the following steps:

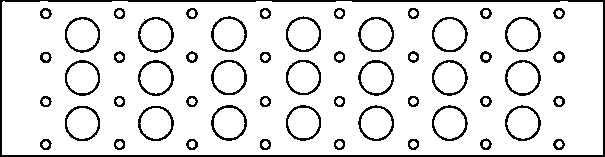

[0058] S11: Determine the length and area of the calibration board according to the actual needs, so as to ensure that the peripheral edge of the calibration board has enough coding patterns to be clearly imaged when shooting at a large angle;

[0059] S12: Design non-repetitive coding patterns of different sizes to ensure that when calibrating the telephoto lens, there is always a coding pattern of a suitable size that can be recognized when calibrating various zoom ring positions of the camera lens;

[0060] S13: Layout the coding pattern into the calibration board.

[0061] Further, in the step S1, by mecha...

Embodiment 2

[0089] A design and detection method of a camera calibration board, comprising the following steps (such as Image 6 shown):

[0090] S1: The overall layout and design of the calibration board;

[0091] S2: measure and save the calibration plate information;

[0092] S3: Camera calibration.

[0093] Further, the step S1 specifically includes the following steps:

[0094] S11: Determine the length and area of the calibration board according to the actual needs, so as to ensure that the peripheral edge of the calibration board has enough coding patterns to be clearly imaged when shooting at a large angle;

[0095] S12: Design non-repetitive coding patterns of different sizes to ensure that when calibrating the telephoto lens, there is always a coding pattern of a suitable size that can be recognized when calibrating various zoom ring positions of the camera lens;

[0096] S13: Layout the coding pattern into the calibration board.

[0097] Further, in the step S1, by mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com