Capacity-grading and set-matching method of lithium ion battery

A technology for lithium-ion batteries and single-cell batteries, applied in the field of lithium-ion batteries, can solve the problems of voltage difference consistency, affecting the service life of the battery, and not considering the internal resistance polarization of the single-cell battery, so as to improve the consistency and improve the use. effect of life

Active Publication Date: 2014-12-17

北京创元万威能源科技有限公司

View PDF6 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the problem that the existing lithium-ion battery grouping method does not consider that the internal resistance polarization of the single battery is easy to occur under high current discharge, and the single battery of the same capacity cannot be fully charged and discharged at the same time, thereby affecting the service life of the battery. The technical problem is to provide a method for distributing the capacity of lithium-ion batteries, which can improve the consistency of the voltage difference of the single batteries in a group when they are discharged with a large current, thereby improving the service life of the batteries in the group

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

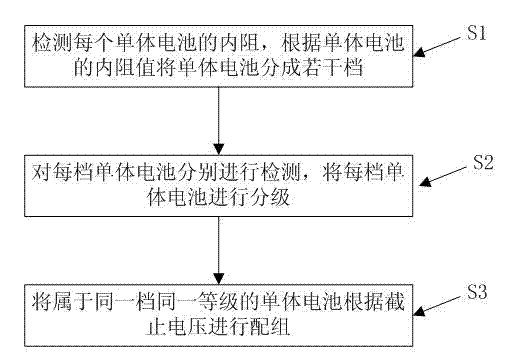

[0025] Embodiment: a kind of lithium-ion battery capacity distribution group method of the present embodiment, such as figure 1 shown, including the following steps:

[0026] S1: Detect the internal resistance of each single battery, and divide the single battery into several levels according to the internal resistance value of the single battery;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

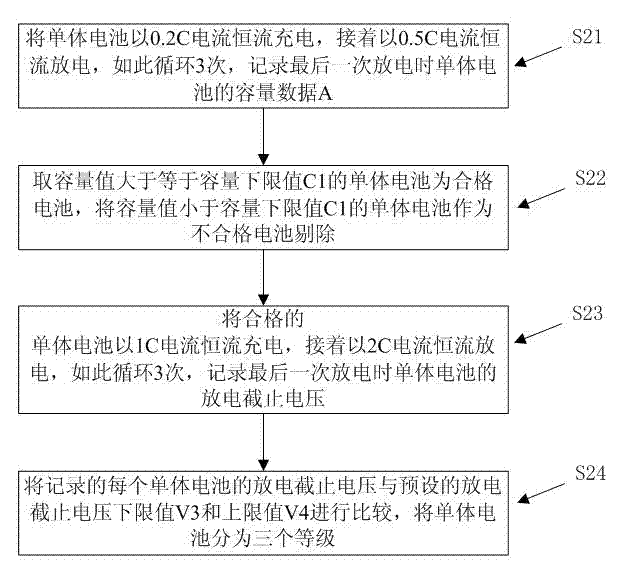

The invention discloses a capacity-grading and set-matching method of a lithium ion battery. The method includes following steps: S1: detecting internal resistance of each single battery cell and dividing the single battery cells into a plurality of grades according to the internal resistances of the single battery cells; S2: respectively detecting each grade of the single battery cells and classifying each grade of the single battery cells; and S3: performing a set-matching operation to the single battery cells in same grade and same classification according to a cut-off voltage. By means of the method, consistency of a voltage difference during heavy-current discharge of the single battery cells which are matched in one set can be increased, thereby prolonging a service life of a set-matched battery.

Description

technical field [0001] The invention relates to the technical field of lithium-ion batteries, in particular to a method for distributing and grouping lithium-ion batteries. Background technique [0002] Due to the deviation of consistency in the production of lithium-ion batteries, it is necessary to combine single batteries with similar performance. If the combination is not done properly, the life of the entire battery will be reduced, and even safety accidents such as explosions and fires will occur. . However, in the prior art, the batteries are generally grouped based on parameters such as the capacity of the single battery, static internal resistance, open circuit voltage, discharge platform time, and charge and discharge efficiency. However, this method has the following disadvantages: it is separated from the actual use of the single battery, and the single battery will usually discharge at a rate of 1C, 2C or even greater during use. Due to internal resist...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/42H01M10/44G01R31/36

CPCH01M10/4207H01M10/4285Y02E60/10

Inventor 潘健健孙延先宋泽斌王玉龙刘启凯

Owner 北京创元万威能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com