Plastic impeller for impeller aerator

An impeller aerator and impeller technology, applied in applications, mechanical equipment, machines/engines, etc., can solve the problems of not being able to achieve oxygen aeration, water cultivation, surge, optional blades, and single form at the same time, so as to facilitate water breaking. Easy to install and move, easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

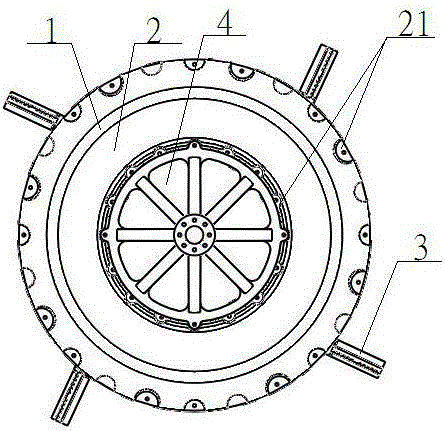

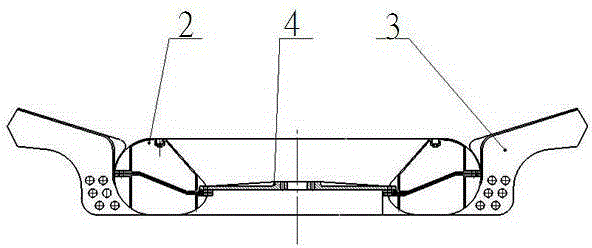

[0030] Such as figure 1 , 2 As shown in . The flange is fixedly connected with the drive shaft of the motor. The sealing floating body 2 is made by integral blow molding process and is an integral hollow ring body. The outer and inner edges of the sealing floating body 2 are provided with a plurality of mounting holes 21. The sealing floating body 2 The mounting hole 21 provided on the outer edge is provided with blades 3, the sealing floating body 2 is provided with a connecting support plate 4 through the mounting hole 21 provided on the inner edge, and the bottom of the sealing floating body 2 is evenly provided with a plurality of limiting grooves 22 along the radial direction, The limit groove 22 is narrower and narrower radially toward the outer edge opening, and is tapered; the connecting support plate 4 is made by injection molding process, including an annular disc 41, a circular disc 43, an annular disc 41 and a circular disc. The discs 43 are fixed into a whole by...

Embodiment 2

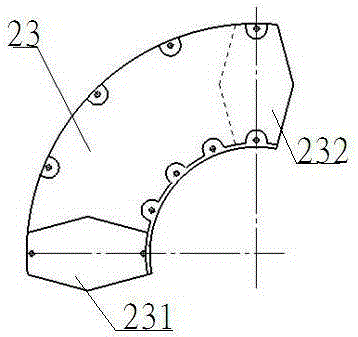

[0032] Such as figure 1 , 2, 3, 4, 5, and 6, the present invention includes an impeller body 1, the impeller body 1 includes a sealing floating body 2, the sealing floating body 2 is provided with blades 3 along the circumferential direction, and the central position of the sealing floating body 2 is provided with a connecting support plate 4, connected The support plate 4 is fixedly connected with the motor drive shaft through the flange, and the sealing floating body 2 is made by blow molding technology, and is composed of a plurality of arc sealing monomers 23, and one end of the arc sealing monomer 23 is a convex connection part 231 , the opposite end is a concave connection part 232, and the adjacent arc sealing monomers 23 are fixedly connected by a convex connection part 231 and a concave connection part 232, and the outer edge and inner edge of the sealing floating body 2 are provided with a plurality of installation holes 21. The sealing floating body 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com