Combined type tea water removing machine

The technology of a compound type and greening machine is applied in the direction of tea processing before extraction, which can solve problems such as inability to achieve, and achieve the effect of preventing tea leaves from being crushed, reducing the baking temperature, and improving the greening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

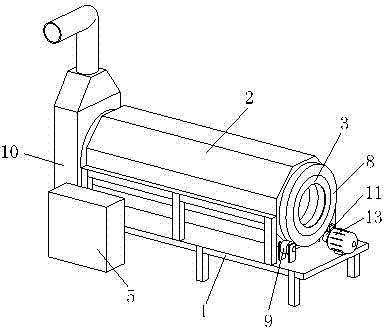

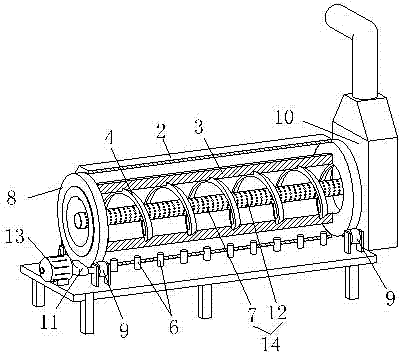

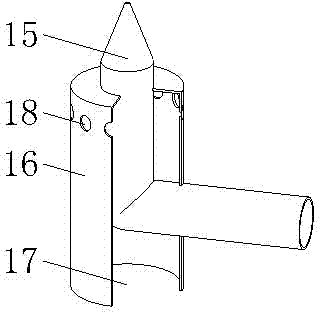

[0017] Embodiment of the present invention: a kind of composite tea greening machine, such as figure 1 and figure 2 As shown, it includes a frame body 1, a thermal insulation shell 2, a rotating drum 3 and a guide vane 4, the thermal insulation shell 2 is fixed on the frame body 1, the rotary drum 3 is plugged into the thermal insulation shell 2, and the two ends of the rotary drum 3 are respectively fixed and installed. There are rollers 8, two groups of bearing rollers 9 are arranged on the frame body 1, the bearing rollers 9 are arranged below the rollers 8 and are rollingly connected with the rollers 8, the frame body 1 is also provided with a roller driving motor 13, and the roller driving motor 13 is decelerated The machine 11 is connected to the rotating shaft of one of the bearing rollers 9; the guide vane 4 is welded on the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com