Split-mounted assembly of filter press

A combination and filter press technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of filter press plane layout and on-site installation troubles, inconvenient operation and maintenance, and increased labor installation costs, etc. Achieve the effects of reducing pipeline installation and layout, reducing equipment installation and maintenance costs, safe operation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

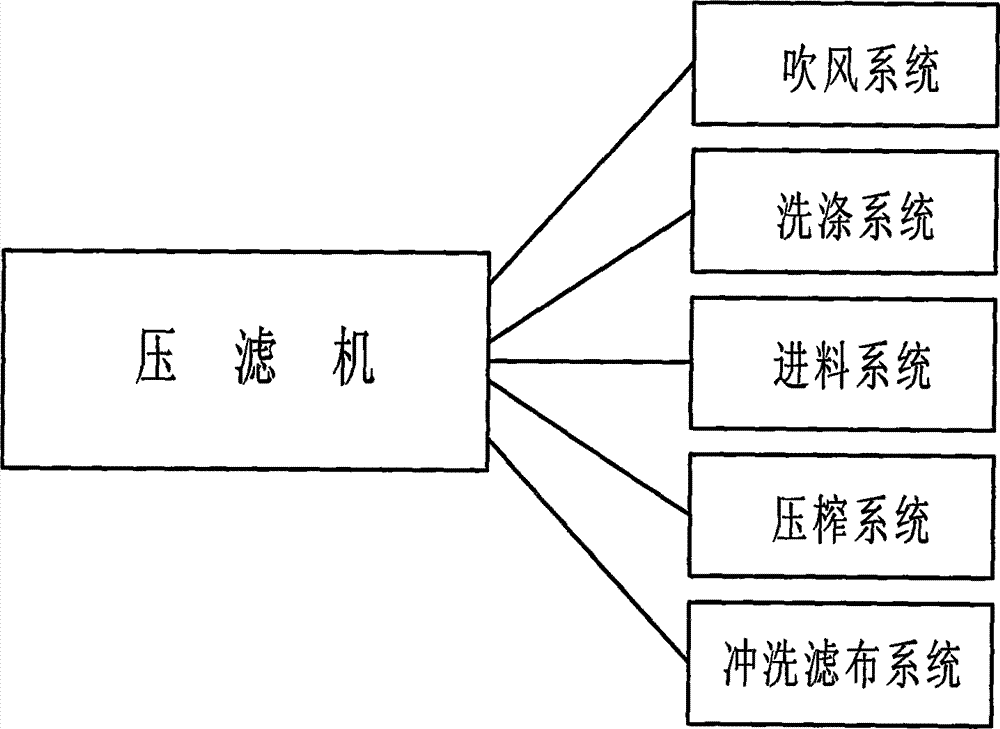

[0009] see figure 1 As shown, the present invention provides a filter press sub-assembly type assembly, which is to assemble the supporting equipment components of the filter press in a welded frame to form an assembly, and then each sub-package The assembly is connected to the filter press, and the supporting equipment connected to the filter press consists of the following assembly: the feed system is provided with feed pumps, control valves, instruments and pipes are installed in a welded frame to form an assembly, and the washing system Install multi-stage pumps, control valves, instruments and pipelines in a welded frame to form a combination, press the system to install squeeze pumps, control valves, instruments and pipelines in a welded frame to form a combination, and the blowing system to set air pressure Machines, gas storage tanks, control valves, instruments and pipelines are installed in a welded frame to form a combination. The flushing filter cloth system is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com