Filtering device at wellhead of water injection well in exploitation of low-permeability oil field

A filter device and water injection well technology, which is applied in the direction of filtration and separation, mining fluid, wellbore/well components, etc., can solve the problems of affecting the filtering effect, easy damage of the winding wire of the filter screen, secondary pollution, etc., and achieve the working life cycle Long-term, prolong service life, reduce corrosion and oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

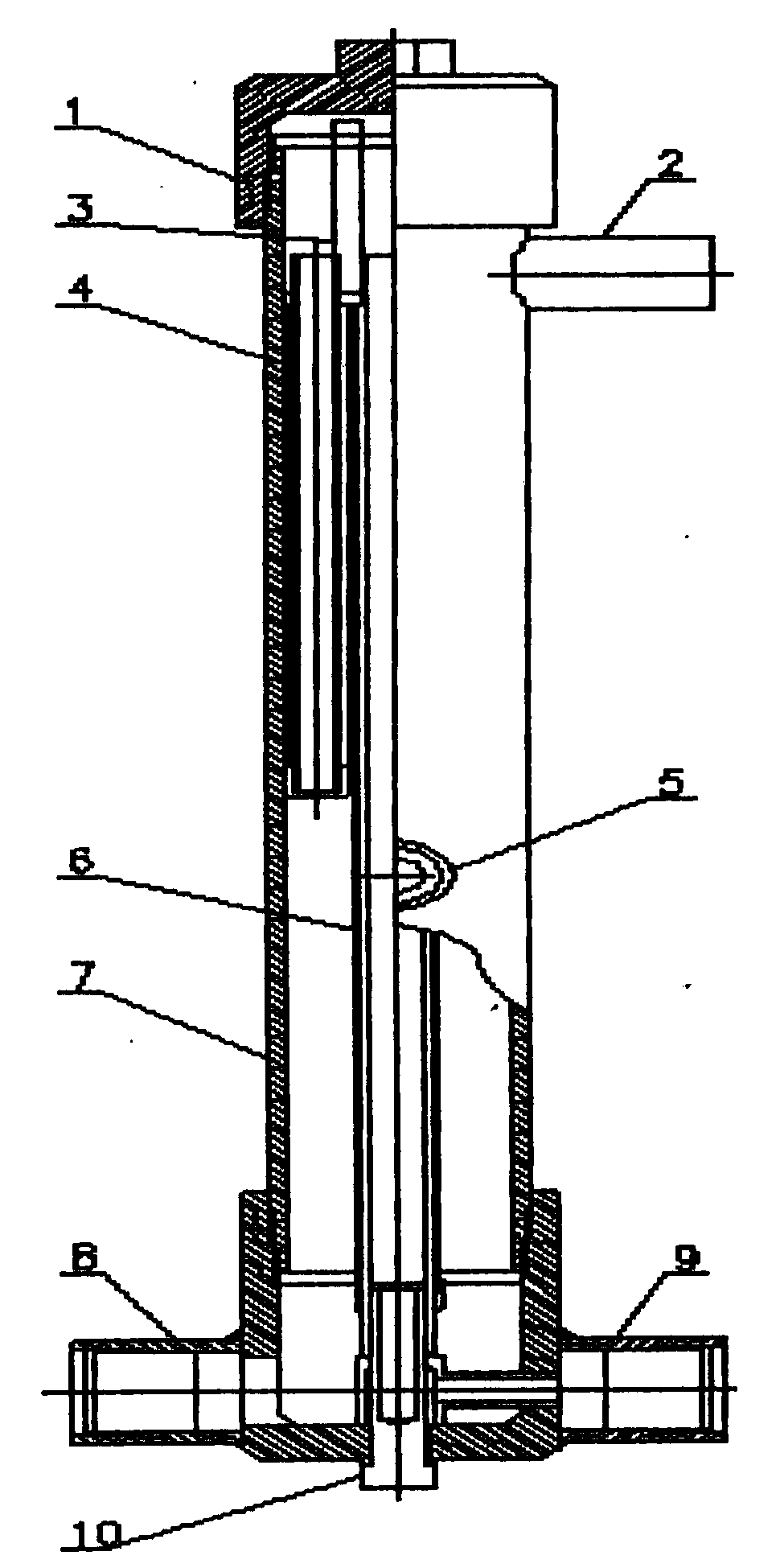

[0017] The structural features of the present invention are further described below in conjunction with the drawings and specific embodiments.

[0018] Such as figure 1 As shown, a wellhead filter device for water injection wells in low-permeability oilfield exploitation includes a filter tube body 7. The upper end of the tube body 7 is closed with a tube body upper cap 1, and the central axis of the tube body 7 runs through a central tube up and down, and the outer side of the central tube The main filter tube 6 is provided, and the inner side of the tube body 7 is provided with four sets of auxiliary filter tubes 4; the middle side wall of the tube body 7 is provided with a liquid inlet 5, and the upper side wall of the tube body 7 is provided with an oil pipe water injection port 2, and the tube body 7 The bottom side wall is provided with a casing water injection port 9 and a sewage outlet 8; the oil pipe water injection port 2 and the casing water injection port 9 are commun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap