Horizontal parting iron-type sand covering modeling system

A sand-covered iron mold and horizontal parting technology, which is applied to molding machines, manufacturing tools, casting molding equipment, etc., can solve problems such as inconsistent product weight, non-standard ventilation holes, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

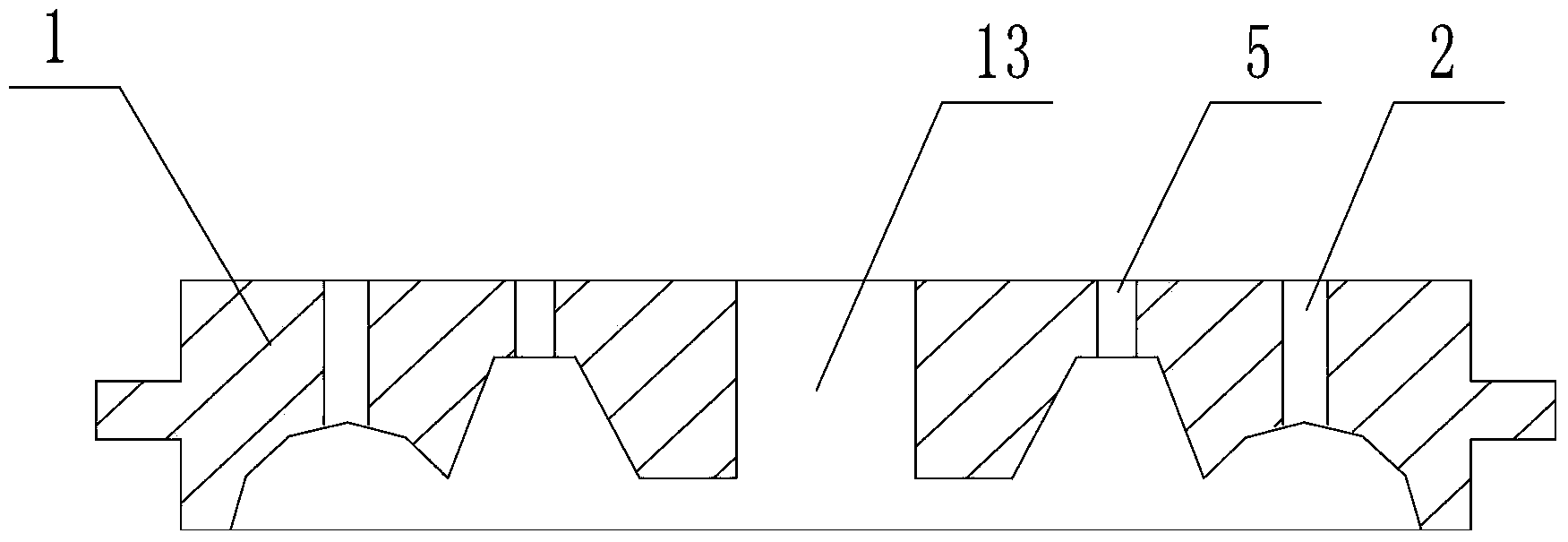

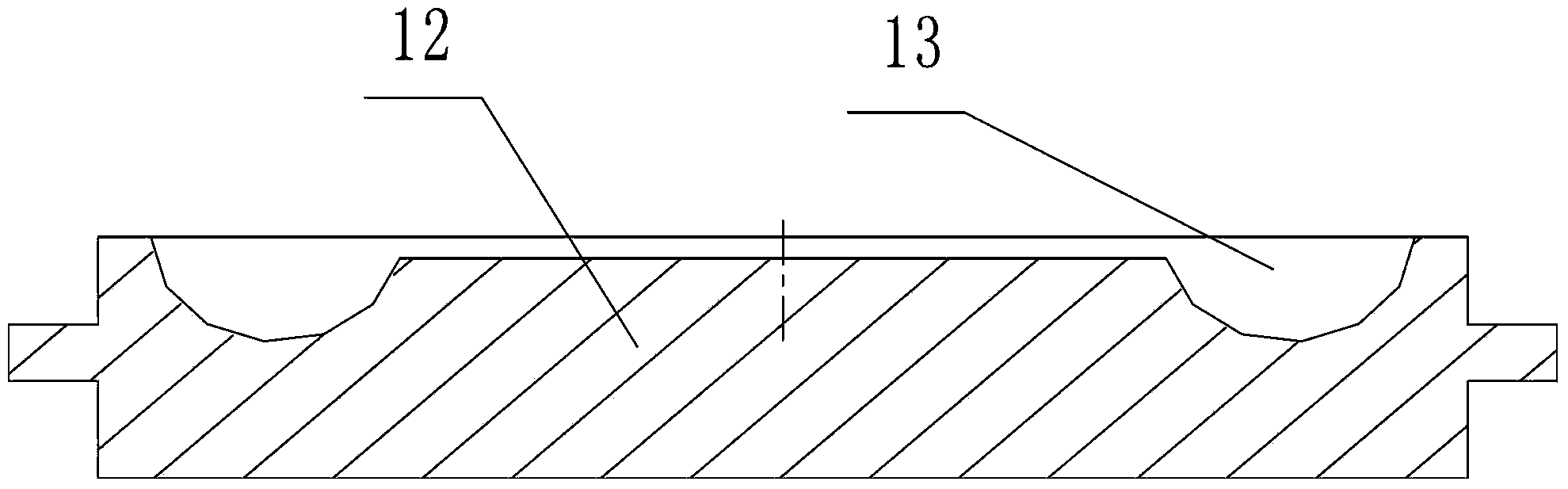

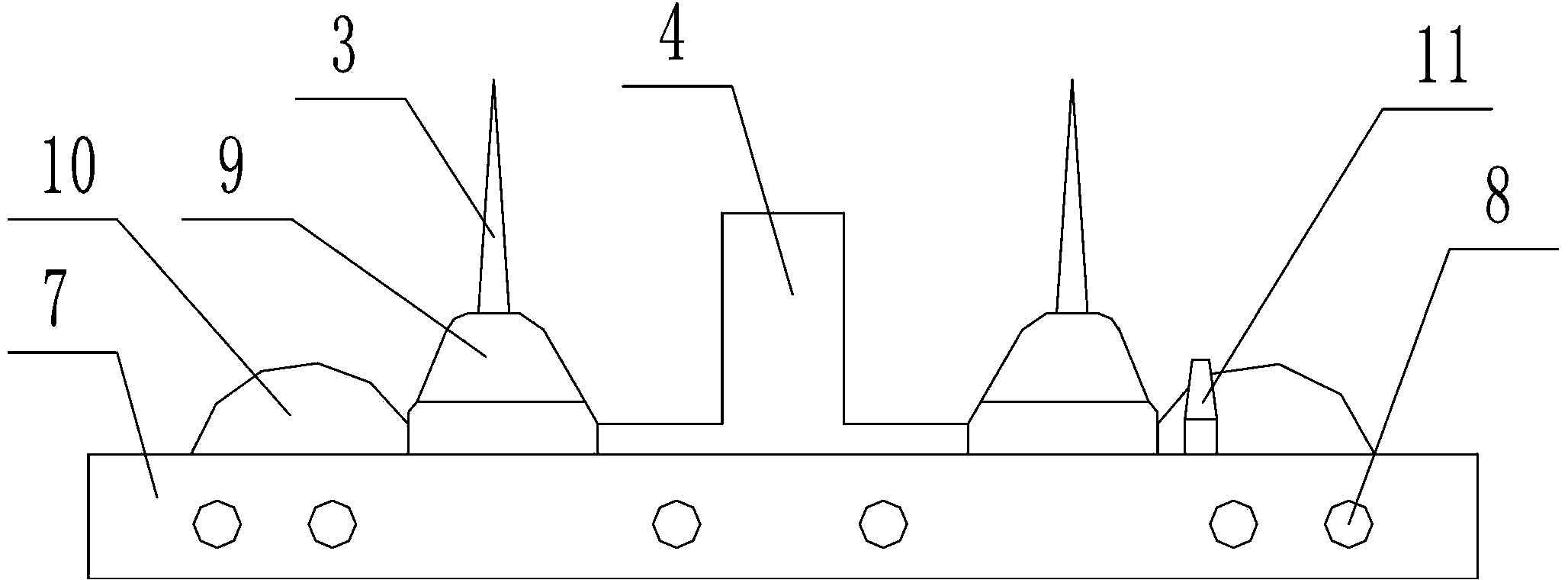

[0017] Such as Figure 1 to Figure 5 It can be seen that the horizontal split iron mold sand-covered molding system includes an iron mold upper mold 1 and an iron mold lower mold 12. Both the iron mold upper mold 1 and the iron mold lower mold 12 are provided with a cavity 13, and the iron mold upper mold 1 Sand injection port 5 and air channel 2 are also provided; heating holes 8 are provided on the pattern plate 7, and the number of heating holes 8 is at least two; sprue system model 4, feeding riser model 9, casting ball model 10 , positioning pins 11 are all fixedly arranged on the template 7, and the sprue system model 4, the feeding riser model 9 and the casting ball model 10 are connected to each other; the upper end of the feeding riser 9 or the casting ball model 10 is fixedly installed with a ventilation Needles 3, and the number of ventilation needles 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com