A square culvert socket ring manufacturing frame

A technology of socket rings and square culverts, which is applied in the field of manufacturing frames, can solve problems such as low precision of socket rings, inaccurate positioning, and increased difficulty in construction, so as to ensure welding accuracy, improve dimensional accuracy, and improve the pass rate of one-time welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

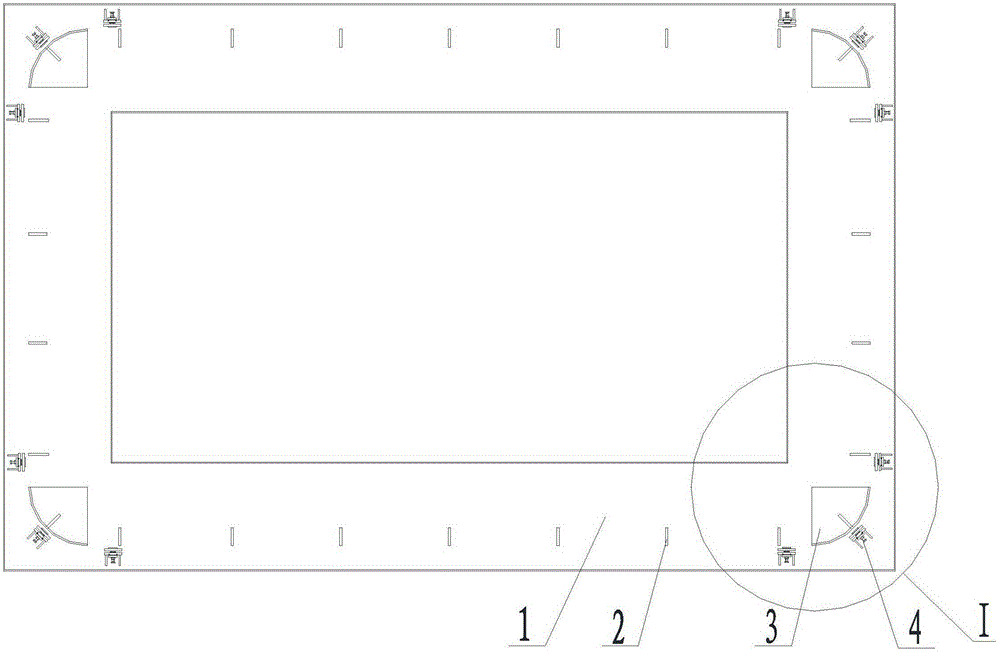

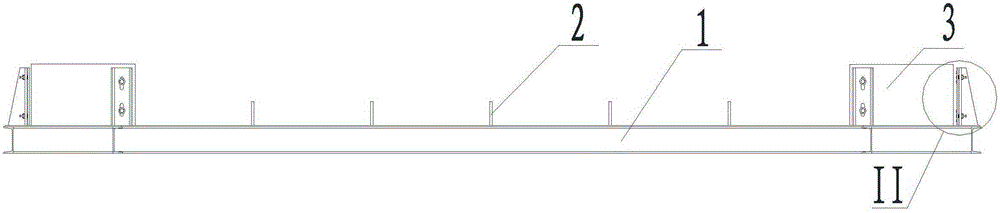

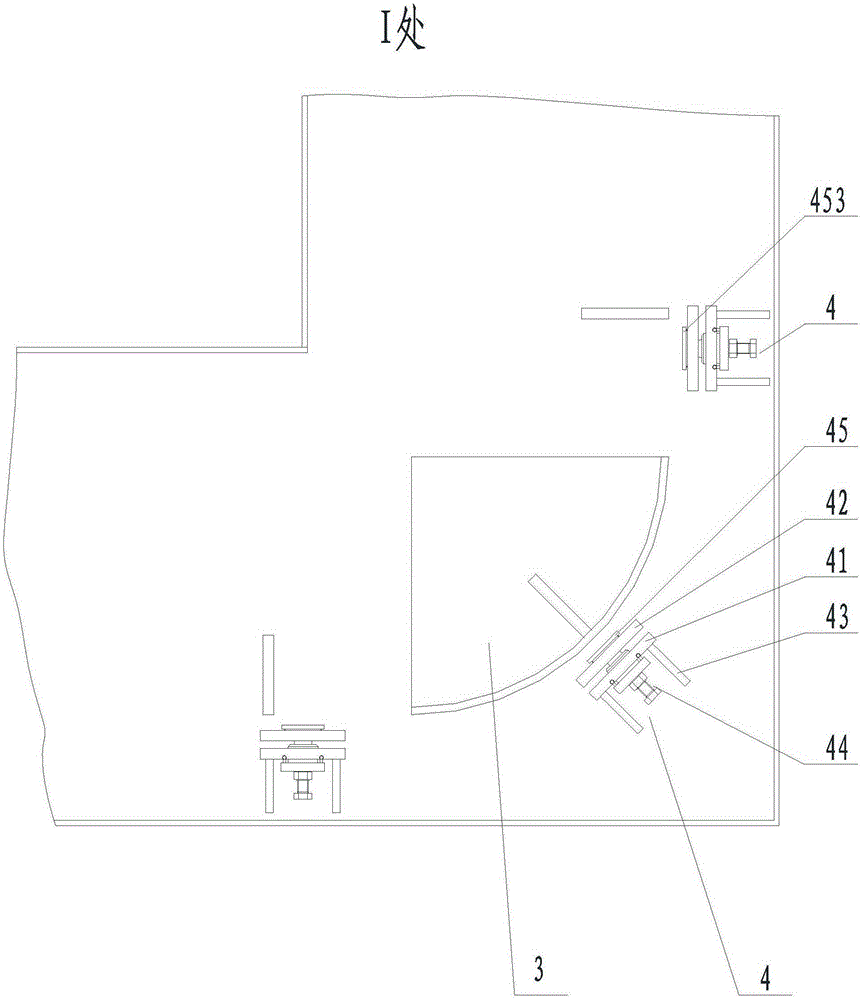

[0029] The present invention as Figure 1-11 As shown, it includes underframe 1, four sets of ring baffles 3 and several limit baffles 2, and said limit baffles 2 are all arranged on the upper plane of said underframe 1, and said annular baffles 3 In the shape of a fan, it is arranged at the four rounded corners of the upper plane of the chassis 1. The limit baffle 2 and the circular ring baffle 3 form a square culvert, in order to prevent the socket ring 5 from being subjected to the limit during welding. The force of the baffle 2 and the ring baffle 3 is inclined outward, and also includes a number of support devices 4, the support devices 4 are arranged on the upper plane of the chassis 1 and are located on the limit baffle 2, The outer side of the ring baffle 3;

[0030] The support device 4 includes a sliding plate 41, a top plate fixing plate 42, at least two groups of sliding and tightening structures 44, a pair of supporting plates 43 and several top plate structures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com