Method for separating broken screw in screw hole

A separation method and screw technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of wedging or tapping, time-consuming, difficult operation, etc., to prevent accidental damage and reduce the difficulty of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

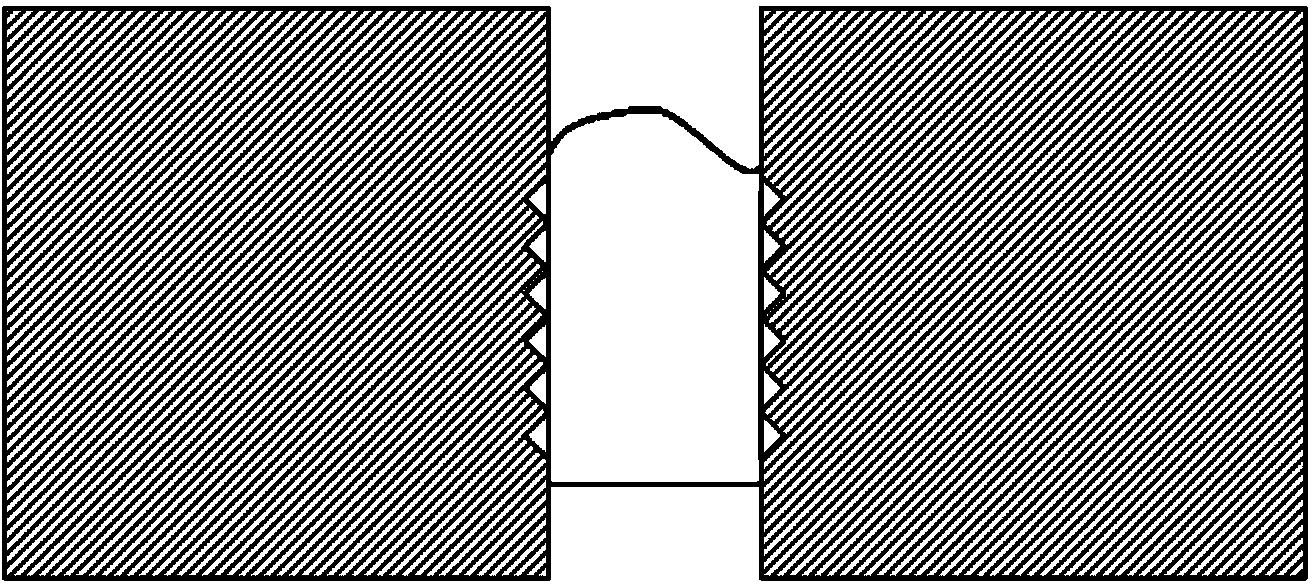

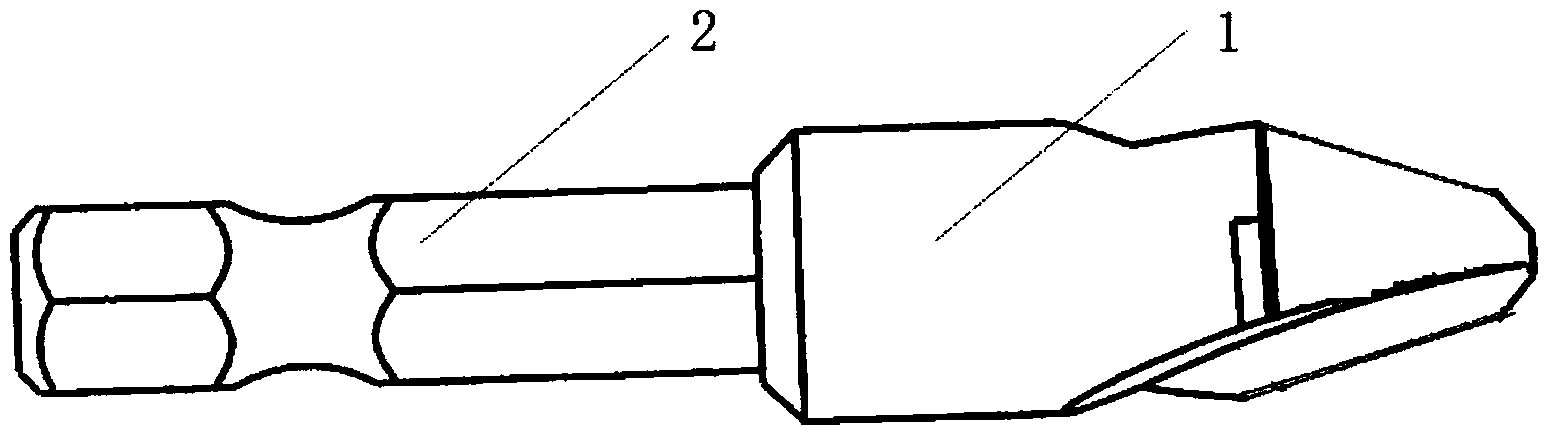

[0024] The main improvement of the separation method of the broken screw in the screw hole provided by the present invention is that before the process of punching the hole and using the broken screw separation tool to separate the broken screw, first pass through the curing of the gel agent mainly containing epoxy resin components, A filling body having sufficient mechanical strength to be suitable for punching, tightly bonded to the section, and having a flat end surface is formed above the section of the broken cap screw.

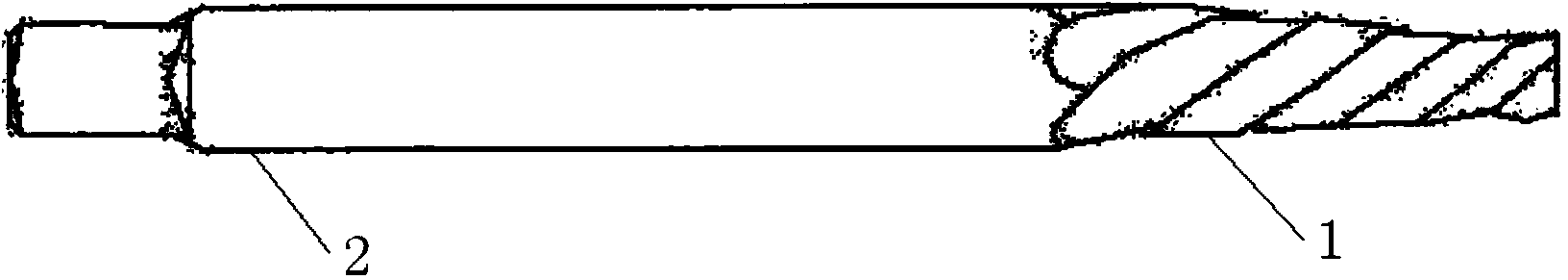

[0025] First, before pouring the gel into the screw hole, a metal inner sleeve in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com