An adjustable clamping aid for grinding holes

An adjustable and auxiliary technology, which is applied in the direction of grinding workpiece supports, can solve problems affecting the size and accuracy of grinding holes, unreasonable structural design, and misalignment of brake hydraulic cylinders, so as to reduce the space size and make up for the lack of contact. Strong, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

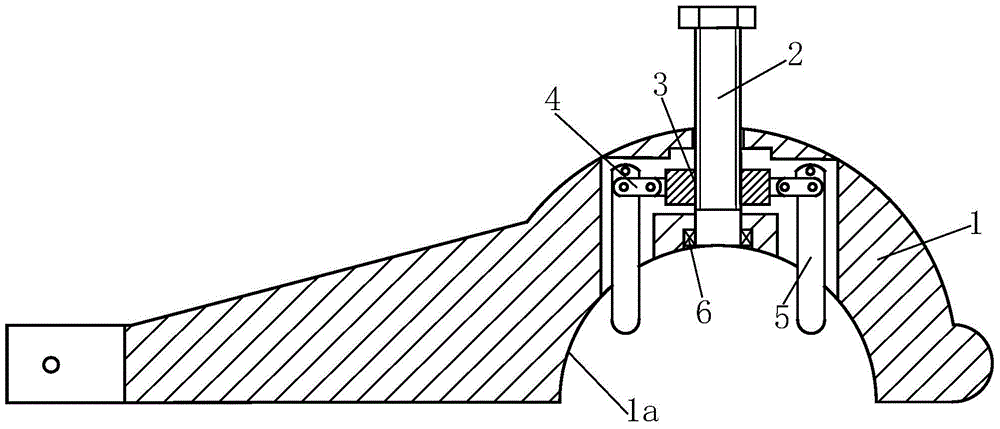

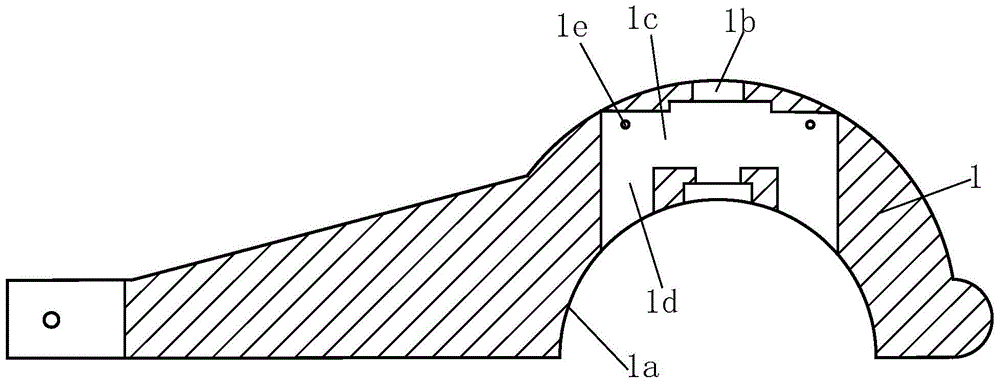

[0016] like Figure 1 to Figure 2 As shown, an adjustable clamping aid for grinding holes, including a pressure rod 1, the right part of the pressure rod 1 is provided with an arc-shaped inner recess 1a, and the upper center of the arc-shaped inner recess 1a is provided with a penetrating The outer connection hole 1b of the pressure rod 1, the middle part of the outer connection hole 1b is provided with an upper swing cavity 1c perpendicular to the outer connection hole 1b, and the left and right ends of the upper swing cavity 1c are symmetrically opened with the upper swing cavity 1c. The vertically connected lower pendulum cavity 1d, the upper part of the lower pendulum cavity 1d is provided with a hanger pin 1e. Depression bar 1 is used as the substrate that other parts are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com