Clamping device

A technology for clamping devices and clamping parts, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., and can solve problems such as complex structures of clamping devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

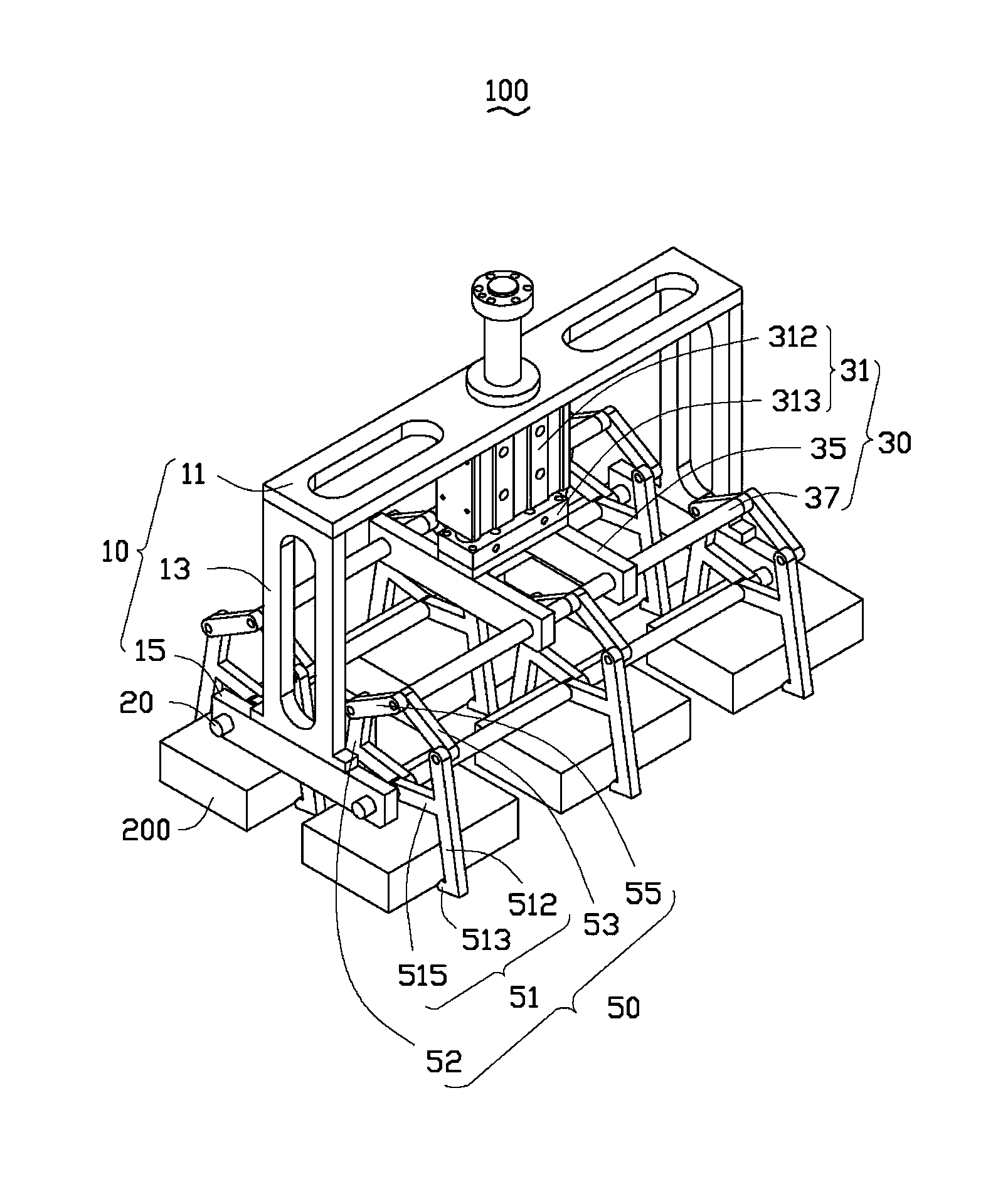

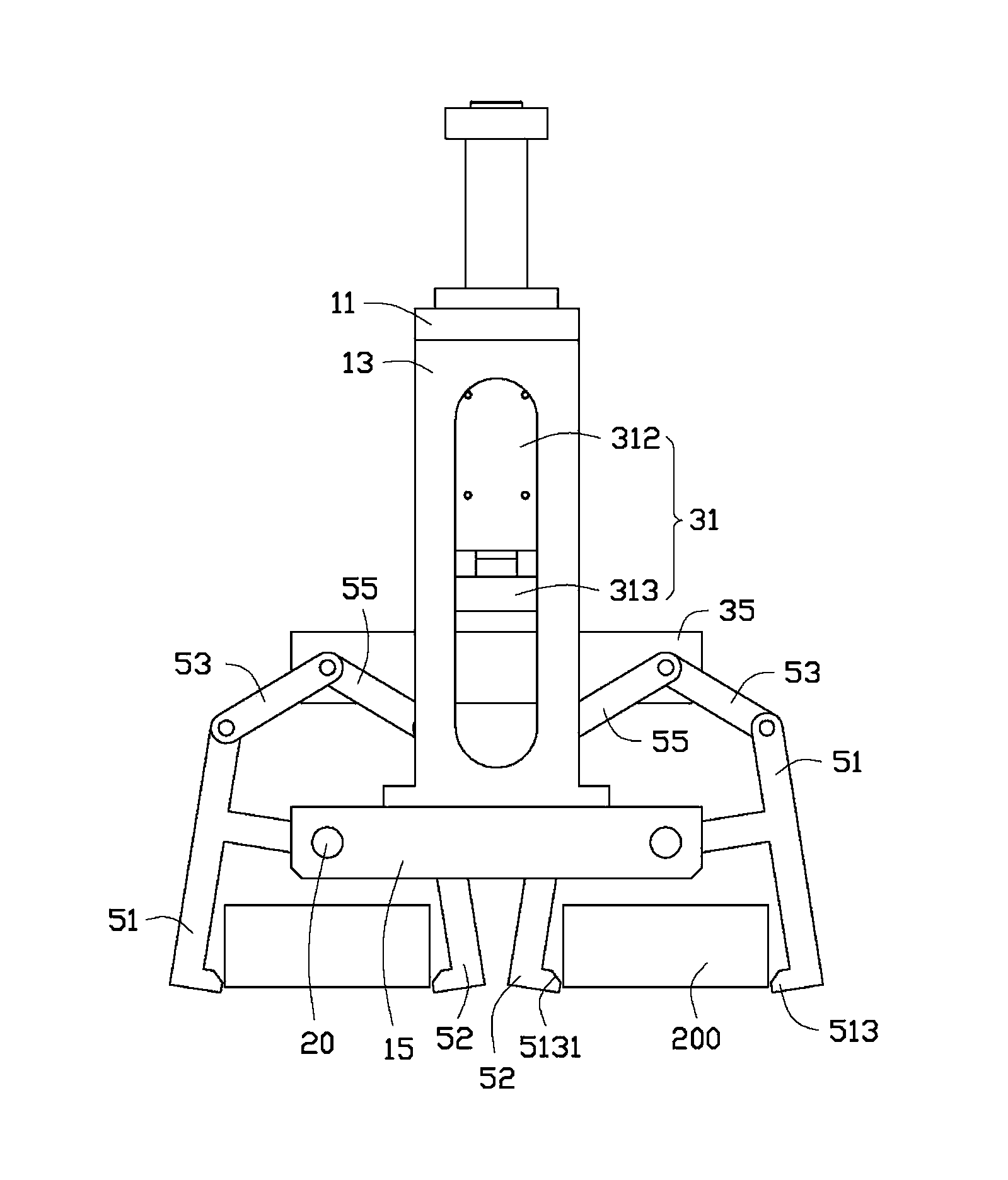

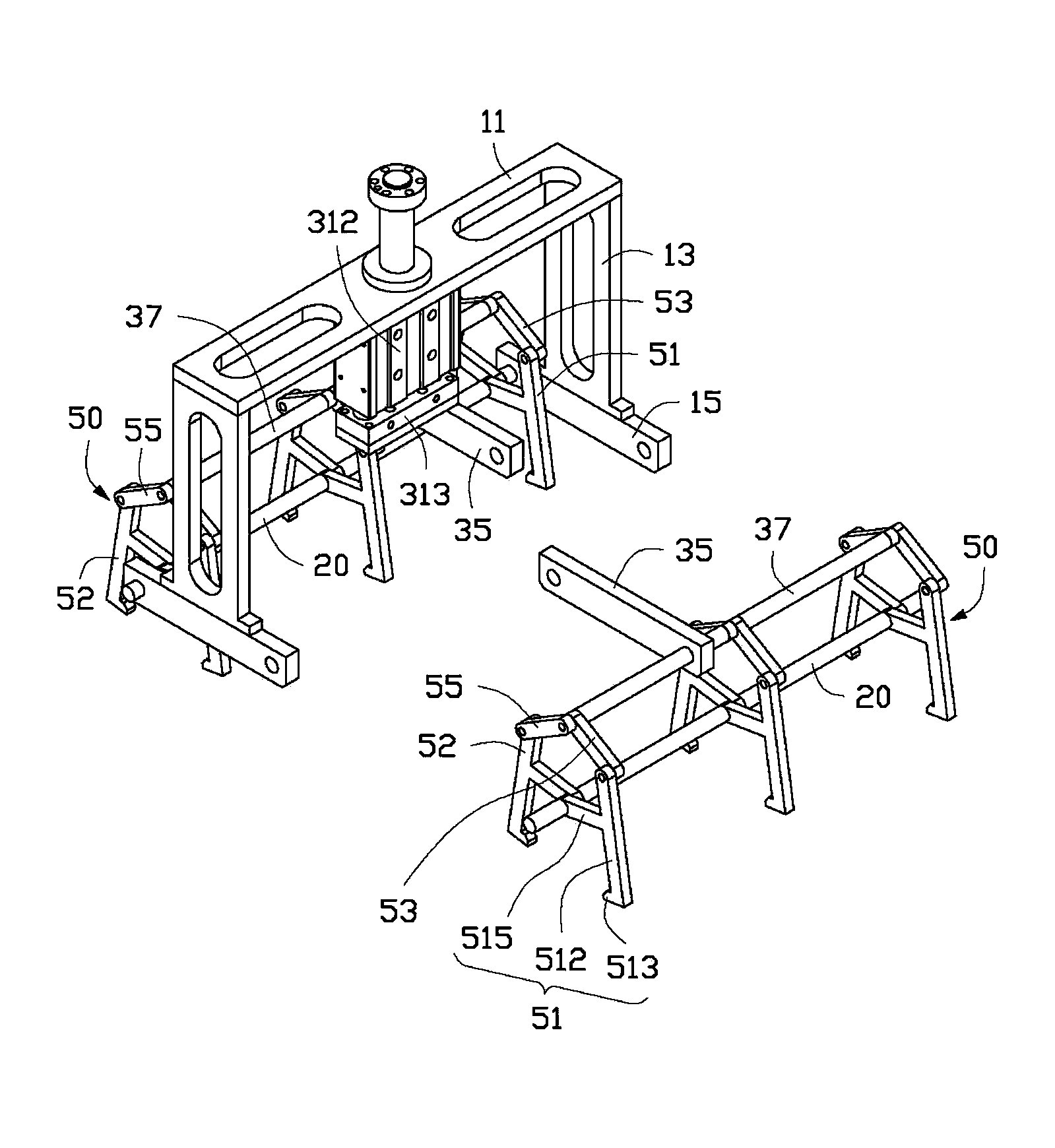

[0012] see figure 1 , the clamping device 100 of the embodiment of the present invention is used to clamp the workpiece 200, and the clamping device 100 can be used in cooperation with a manipulator (not shown in the figure), and the workpiece 200 can be transported and other operations under the control of the manipulator.

[0013] The clamping device 100 includes a support frame 10 , two fixed shafts 20 , a driving mechanism 30 and six clamping components 50 . The drive mechanism 30 is installed on the support frame 10, and the two fixed shafts 20 are respectively fixed and installed on the support frame 10 in parallel. The clamping assembly 50 is pivotally connected to the two fixed shafts 20 and connected with the drive mechanism 30 so that Driven by the driving mechanism 30 , the clamping assembly 50 clamps or releases the workpiece 200 .

[0014] Please also see figure 2 , the supporting frame 10 includes a base portion 11 , a supporting portion 13 and two fixing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com