Large-section plastic-wood cutting machine

A wood cutting machine and large-section technology, which is applied in metal processing and other directions, can solve the problems of difficult cutting of small equipment, the cost and high cost of large cutting machines, etc., and achieve the effects of low cost, convenient manual operation, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

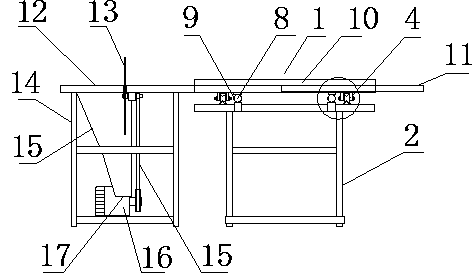

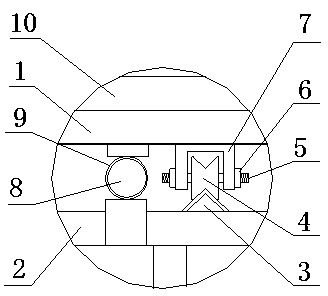

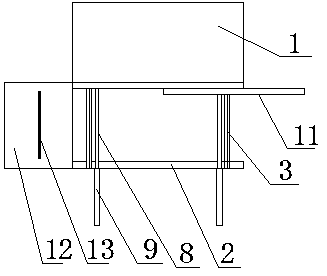

[0025] see figure 1 , Figure 5 A kind of large section plastic wood cutting machine of the present invention of the present invention, comprises frame 2, is provided with console 1 on frame 2, and described console 1 is connected on frame 2 by sliding device, and described operation Platform 1 also has reset pull bar 11. One end of frame 2 is saw table 12, and saw table 12 is fixed on the saw table support 14, and the middle part of saw table 12 is provided with elongated opening, and circular saw 13 is exposed from the opening of saw table 12, and circular saw 13 Drive by motor 16; Motor 16 is fixed on the bottom of saw table support 14, and motor 16 is connected with circular saw 13 by conveyer belt 15; Saw table support 14 is provided with collection device below circular saw 13; Described coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com