Plastic sucking molding method of flowerpots

A technology of blister molding and processing methods, applied in the field of flower pots, can solve problems such as high production costs, low yield, and complex mold design, and achieve the effects of convenient transportation, upgrading grades, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

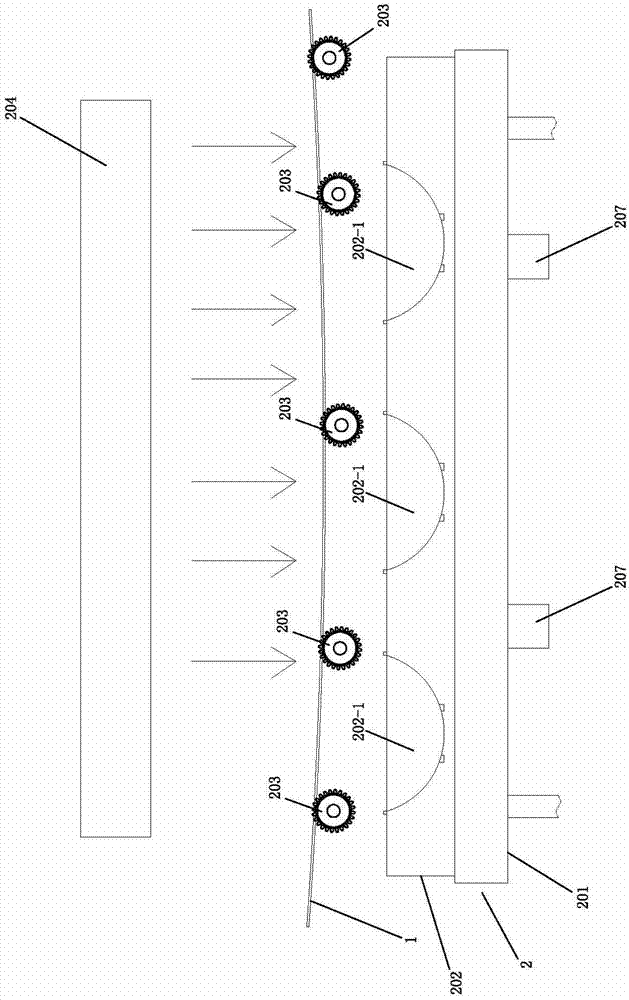

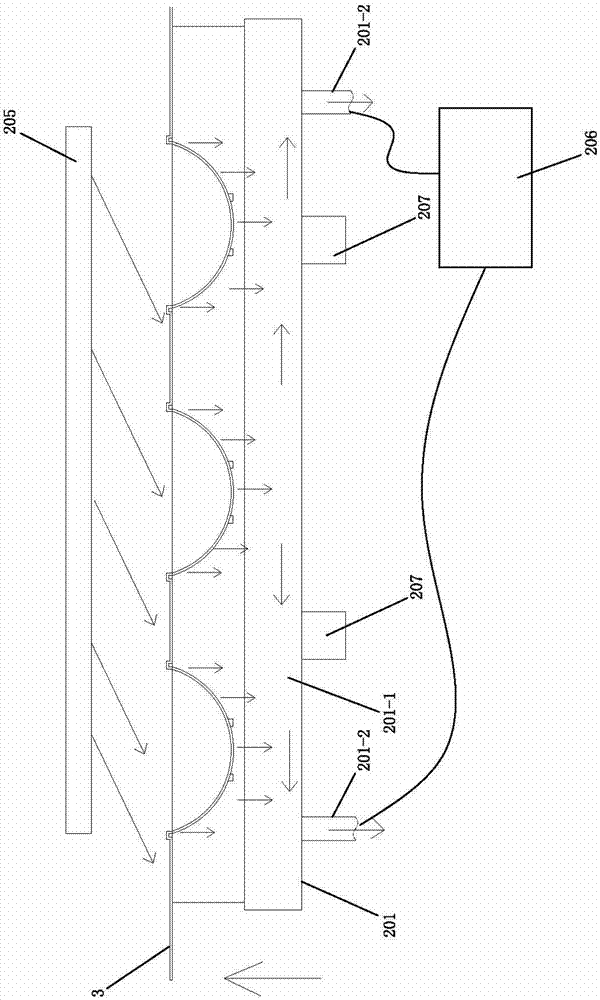

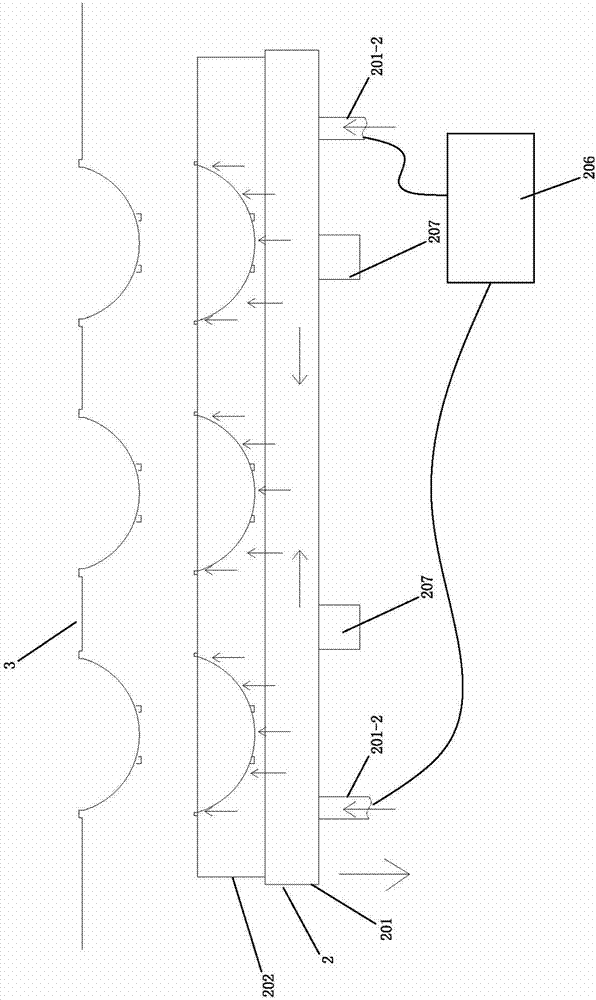

[0025] Such as Figure 1 to Figure 5 Shown, the blister molding processing method of flowerpot is characterized in that, comprises the following steps:

[0026] (1) extrusion

[0027] a. Clean and screen recycled waste materials made of APET and crush them into pieces;

[0028] b. Crystallize and melt the fragments through the crystallization tank of the material molding machine at a temperature of 160°C, and then extrude the completely melted plastic through the outlet of the extruder of the plastic machine to extrude the plastic sheet 1;

[0029] (2) Blister molding

[0030] a. Import the formed plastic sheet 1 into the integrated plastic-absorbing equipment 2 for plastic-absorbing molding. The integrated plastic-absorbing equipment 2 includes a chassis 201 and a mold 202 installed on the chassis 201. The mold 202 is based on the shape of the flowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com