Carton packaging machine

A packaging machine and carton technology, applied in the field of machinery and equipment, can solve the problems of large impact of the transfer mechanism, small space occupation, and uneven feeding of the carton, and achieve the effect of increasing space and stable feeding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

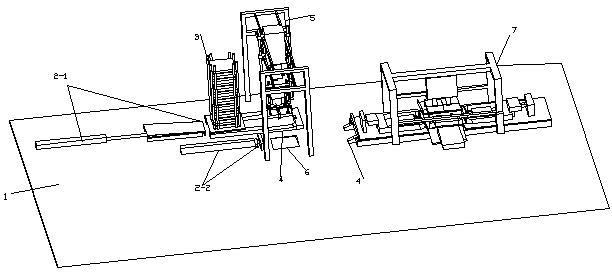

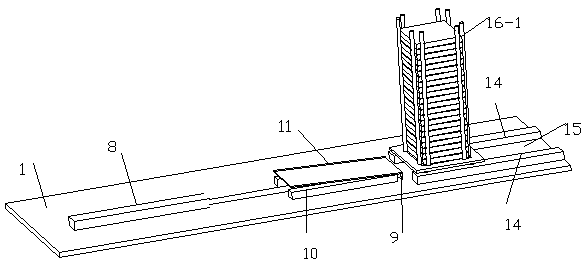

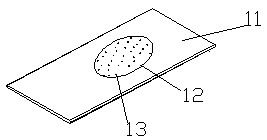

[0035] combine Figure 1-2 : Carton packaging machine, including workbench 1, conveying device 4, feeding device 3, pushing device A2-1, shifting device 5, wrapping device 6, pushing device B2-2, sealing device 7; conveying device 4 is The workbench 1 is fixed with bosses 14 parallel to both sides, and a conveying trough 15 for conveying cartons is formed between the two bosses 14; And be connected with described boss 14; Push device A2-1, push device B2-2 comprise hydraulic cylinder 8, push block 9 respectively, the movable end of hydraulic cylinder 8 is fixedly connected with push block 9, push device A2-1, push The devices B2-2 are respectively fixed on the workbench 1 and are located in the opposite direction of the carton conveying direction; the upper end of the pushing block 9 of the pushing device A2-1 is connected with an upwardly inclined support plate 11, and the conveying of the support plate 11 and the conveying trough 15 The angle in the opposite direction of th...

Embodiment 2

[0038] The difference from Embodiment 1 is that the angle between the supporting plate 11 and the opposite direction of the conveying direction of the conveying trough 15 is 20 degrees, and the whole carton packaging process goes smoothly.

Embodiment 3

[0040] The difference from Embodiment 1 is that the angle between the supporting plate 11 and the opposite direction of the conveying direction of the conveying trough 15 is 5 degrees, and the whole carton packaging process goes smoothly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap