Steering rear lift shaft

A technology of lifting shaft and steering knuckle arm, applied in steering mechanism, steering mechanism of deflectable wheel, transportation and packaging, etc., can solve the problem that the outer radius of the whole vehicle does not work, the active steering cannot be realized, and the bearing capacity of the whole bridge is weak. and other problems, to achieve the effect of reducing fuel consumption, structural stability, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

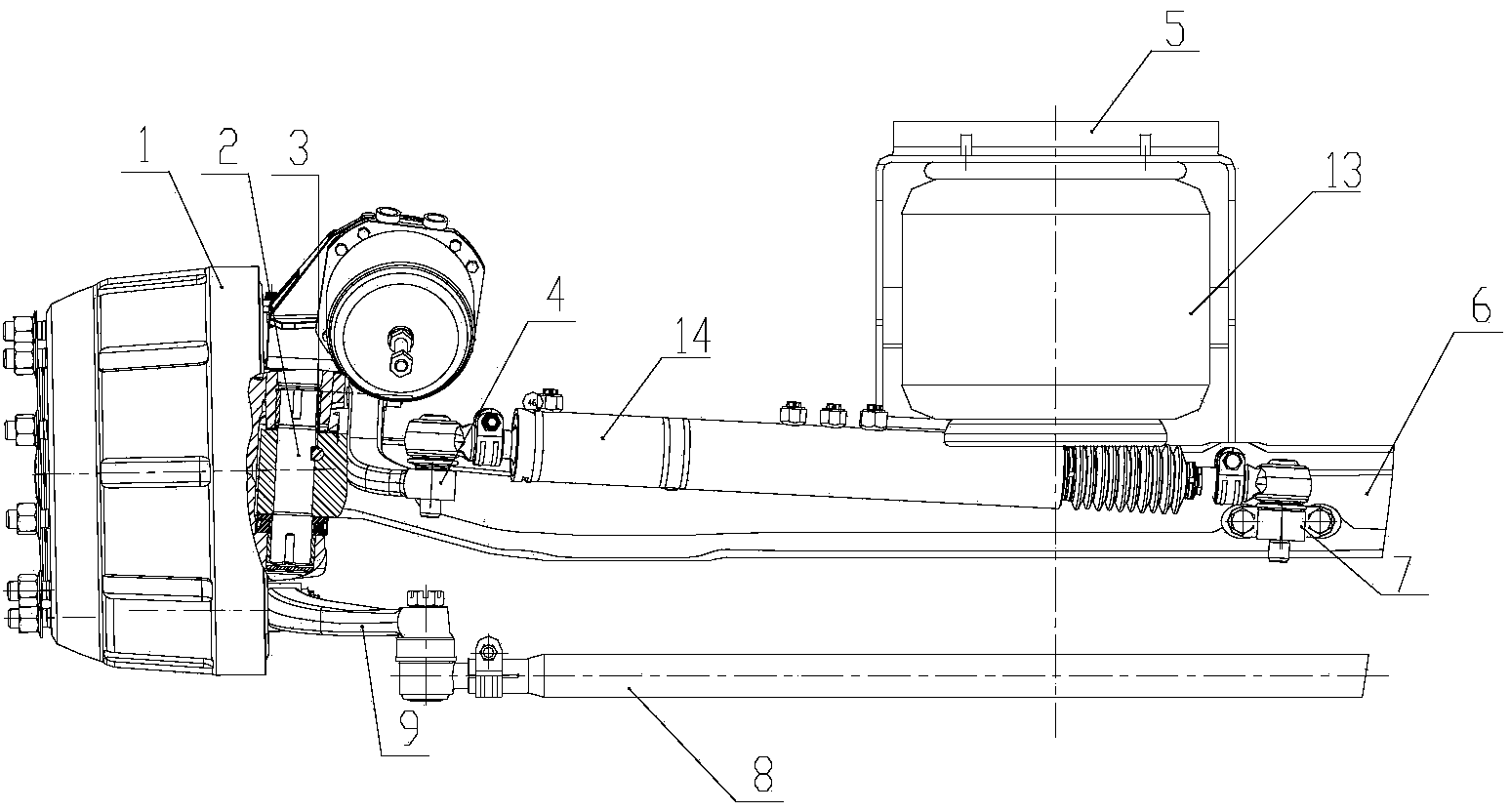

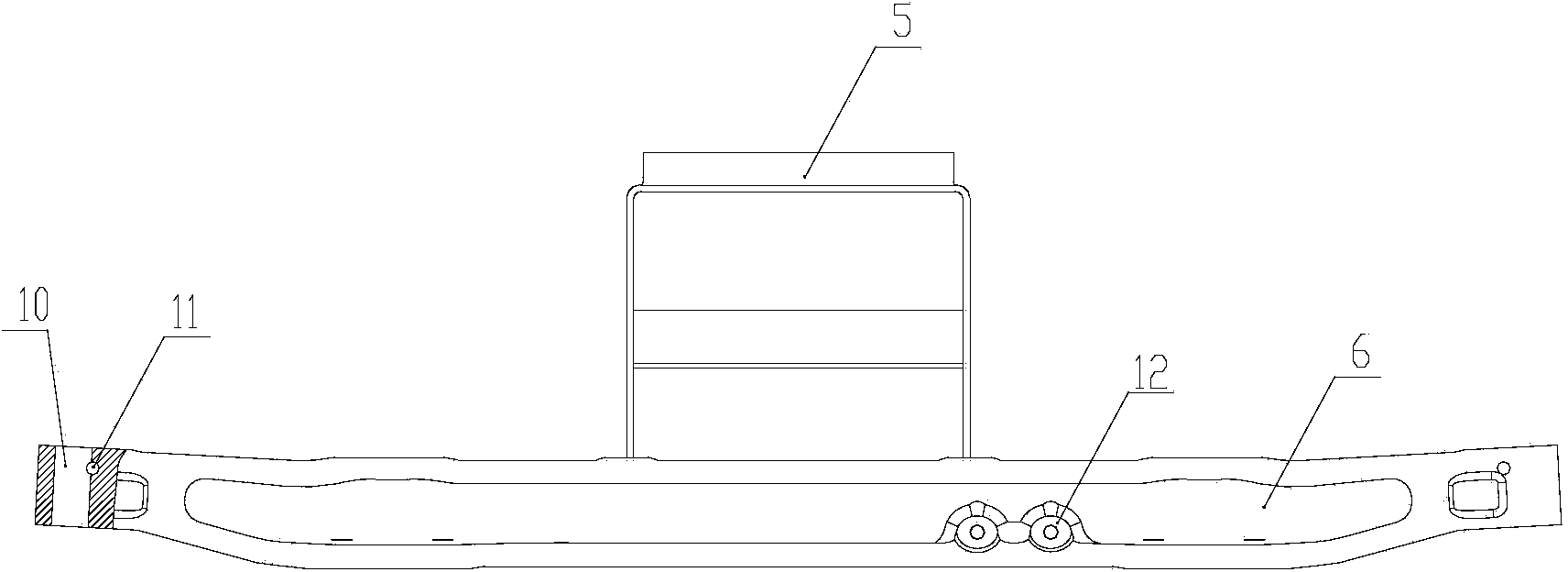

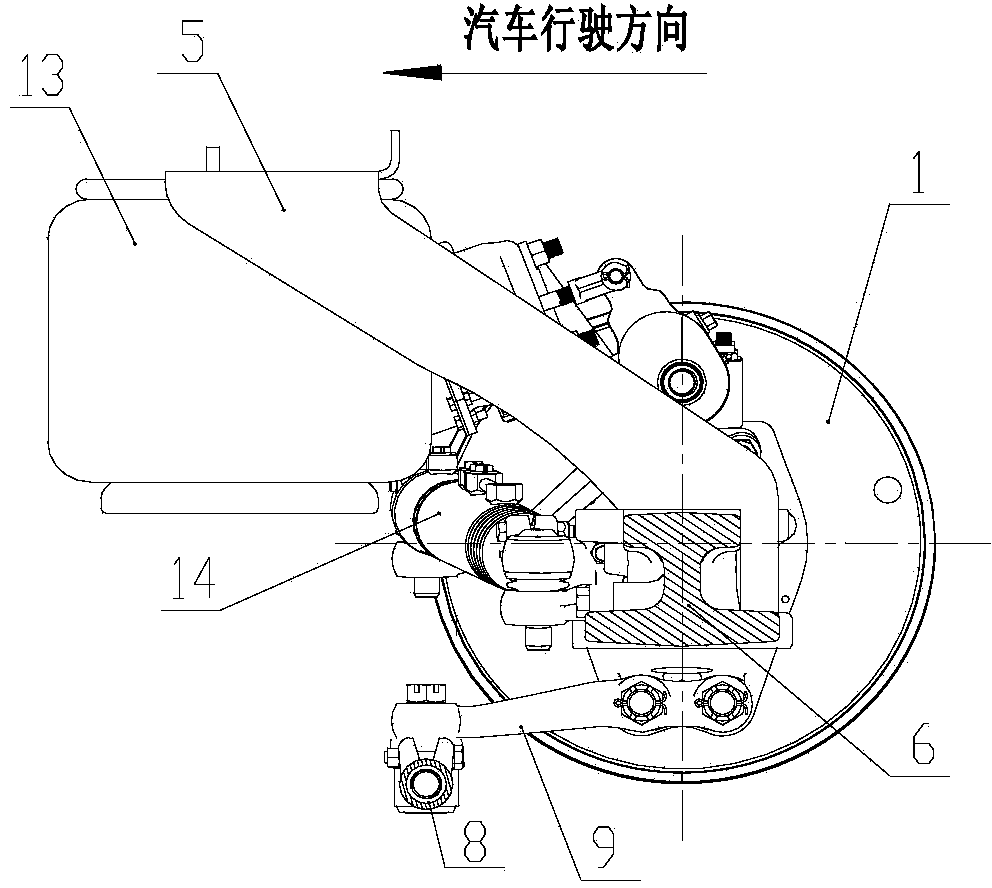

[0023] Such as figure 1 As shown, a lifting shaft after steering includes a support shaft assembly, a wheel rim assembly 1, a steering knuckle arm 4, an oil cylinder support 7, a steering tie rod arm 9, a tie rod assembly 8, a king pin 2, and a limit screw 3. The support shaft assembly is a welded assembly, which is welded by the support shaft 6 and the bracket assembly 5. Among them, the support shaft 1 is an integral cast steel I-beam structure with stronger bearing capacity and more reliable structure. Pin holes 10 and limit screw mounting holes 11, the side of the support shaft 6 are processed with mounting holes 12 for connecting the oil cylinder support. The bracket assembly 5 is formed by punching and welding steel plates.

[0024] The wheel rim assembly 1 is assembled on the support shaft assembly through the kingpin 2, and the limit screw 3 cooperates with the kingpin 2 and the support shaft 6 through the limit screw installation hole 11 to lock the kingpin 2 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com