Acrylamide copolymer as well as preparation method and application of acrylamide copolymer

A technology of acrylamide series and copolymers, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limitations, poor temperature resistance and shear resistance of polyacrylamide jelly, and achieve the preparation method Simple, good high temperature shear resistance, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

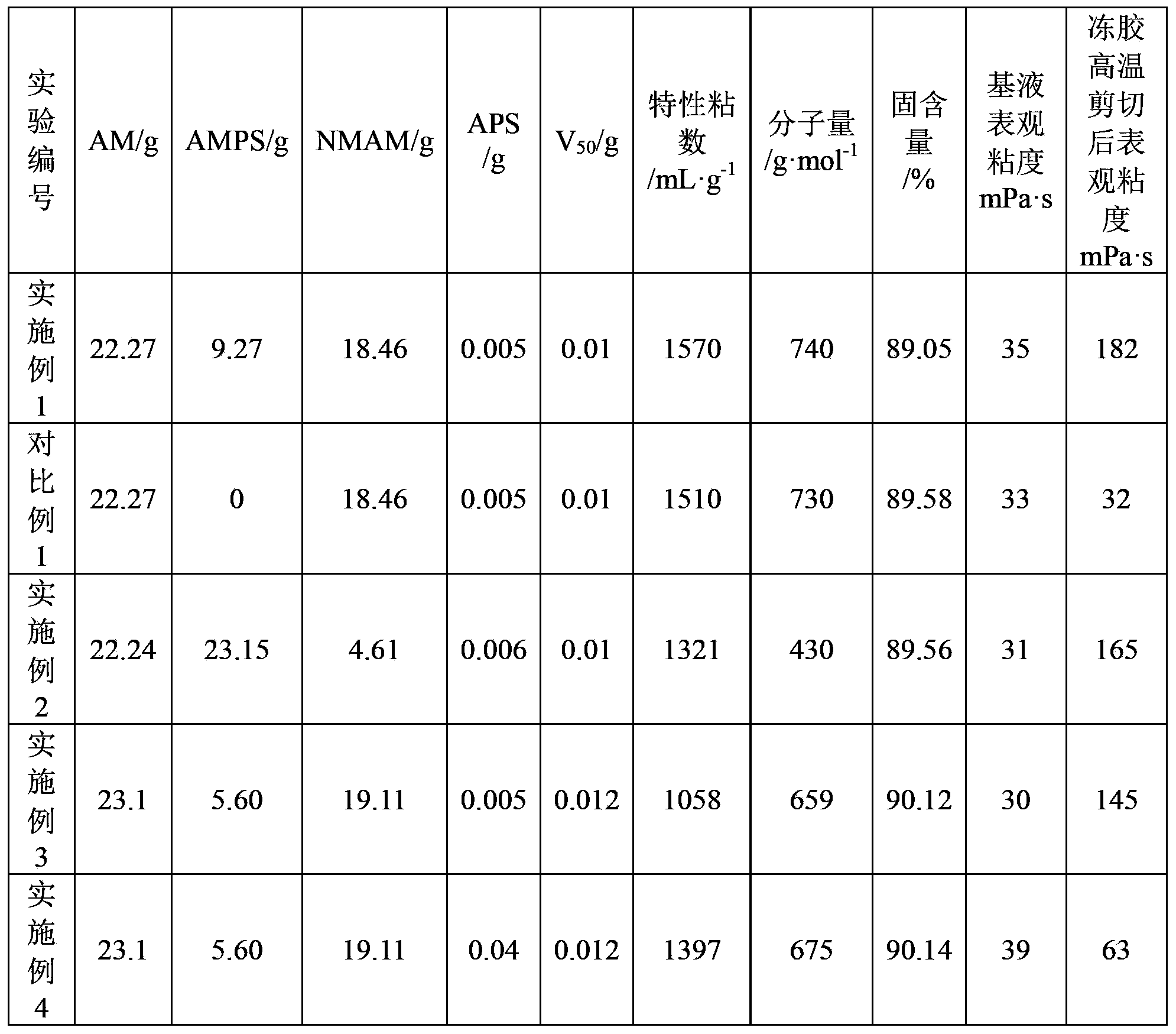

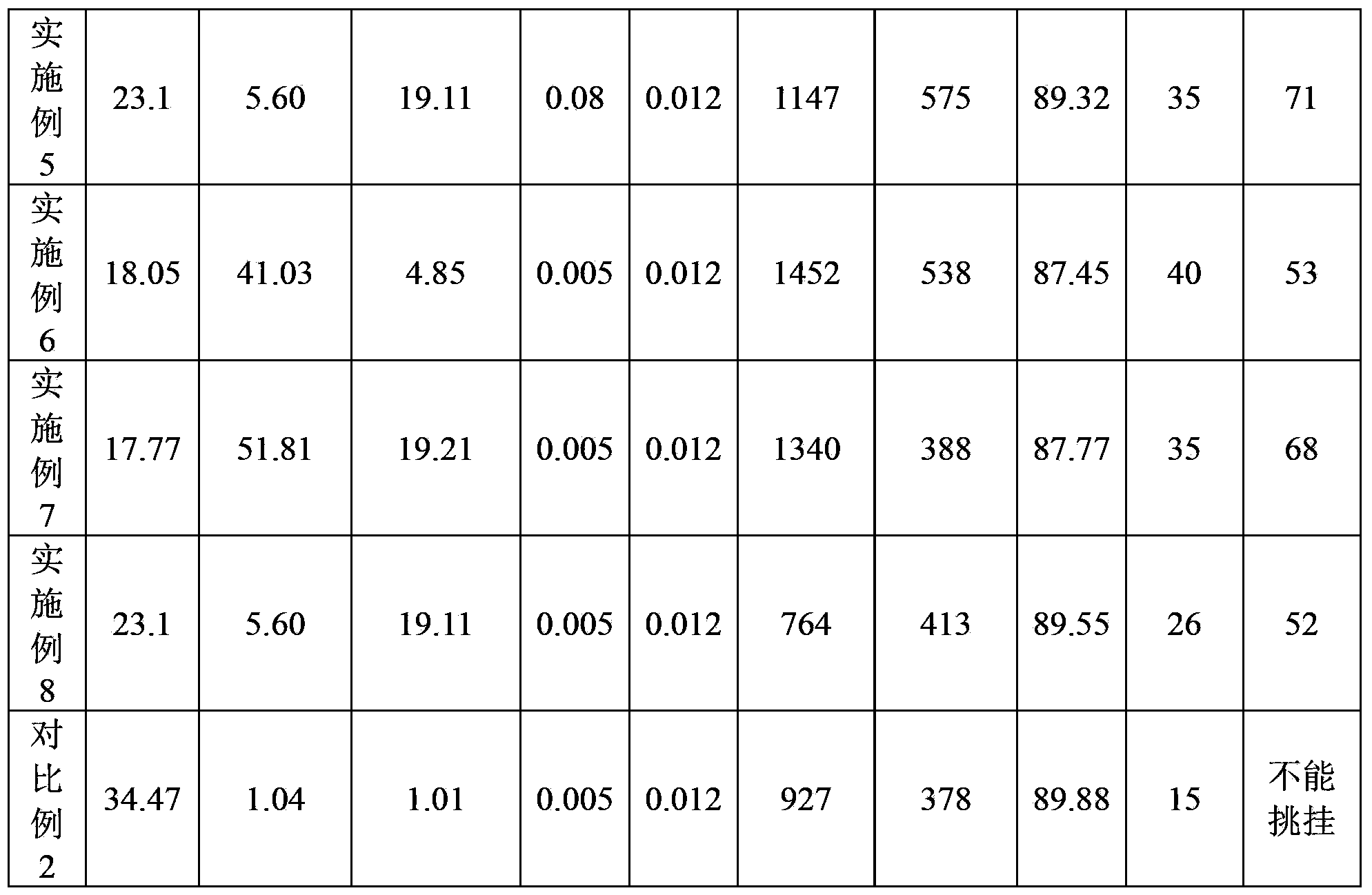

Embodiment 1

[0057] This example is used to illustrate the acrylamide copolymer and its preparation method.

[0058] 22.27g of acrylamide (AM), 9.27g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 18.46g of N-methylolpropanesulfonic acid (AMPS) were sequentially added to a 250mL reactor under cooling at 0°C Add 180g of water to NMAM, stir to dissolve the monomer completely, and obtain an aqueous solution of the monomer mixture. Adjust the pH to 5.5 with sodium hydroxide solution 2 After bubbling for 30 minutes, add 0.01 g of 2,2'-azobis(2-amidinopropane) dihydrochloride (V50), 0.005 g of ammonium persulfate (APS) and 0.0027 g of sodium bisulfite in sequence, The reaction mixture was polymerized at 20° C. for 1 hour, and then the reaction mixture was heated to 60° C. for 2 hours. The colorless transparent viscoelastic colloid P1 of the acrylamide copolymer was obtained by discharging. After the acrylamide copolymer colloid P1 was granulated, dried, pulverized and sieved, various...

Embodiment 2

[0064] This example is used to illustrate the acrylamide copolymer and its preparation method.

[0065] Under the cooling condition of 0°C, 22.24g of acrylamide, 23.15g of 2-acrylamide-2-methylpropanesulfonic acid and 4.61g of N-methylolacrylamide were successively added to a 250mL reactor, and 96.7g g of water, stirred to dissolve the monomer completely, and obtained an aqueous solution of the monomer mixture. Adjust the pH to 8.5 with sodium hydroxide solution. Pass N 2 After bubbling for 30 minutes, 0.01 g of 2,2'-azobis(2-amidinopropane) dihydrochloride (V50), 0.006 g of ammonium persulfate and 0.0027 g of sodium bisulfite were sequentially added to make the reaction mixture The reaction was carried out at 8° C. for 3 hours, and then the reaction mixture was heated to 70° C. for 1 hour. The colorless transparent viscoelastic colloid P2 of the acrylamide copolymer was obtained by discharging. After the acrylamide copolymer colloid P2 was granulated, dried, pulverized an...

Embodiment 3

[0069] This example is used to illustrate the acrylamide copolymer and its preparation method.

[0070] Under cooling conditions at 0°C, 23.1g of acrylamide, 5.60g of 2-acrylamide-2-methylpropanesulfonic acid and 19.11g of N-methylolacrylamide were sequentially added to a 250mL reactor, and 120g of water, stirring to completely dissolve the monomers to obtain an aqueous solution of the monomer mixture. Adjust the pH to 7.5 with sodium hydroxide solution. Pass N 2 After bubbling for 30 minutes, 0.012 g of 2,2'-azobis(2-amidinopropane) dihydrochloride (V50), 0.005 g of ammonium persulfate and 0.027 g of sodium bisulfite were successively added to make the reaction mixture The polymerization reaction was carried out at 10° C. for 2 hours, and then the reaction mixture was heated to 40° C. for 2 hours. The colorless and transparent viscoelastic colloid P3 of the acrylamide copolymer was obtained by discharging. After the acrylamide copolymer colloid P3 was granulated, dried, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap