Double-station mobile crystallizer vacuum electroslag furnace

A crystallizer and double-station technology, which is applied in the field of double-station mobile crystallizer vacuum electroslag furnace, can solve the problems of high manufacturing cost, low operation efficiency, complex structure, etc., to reduce processing cost, improve product quality, contact large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

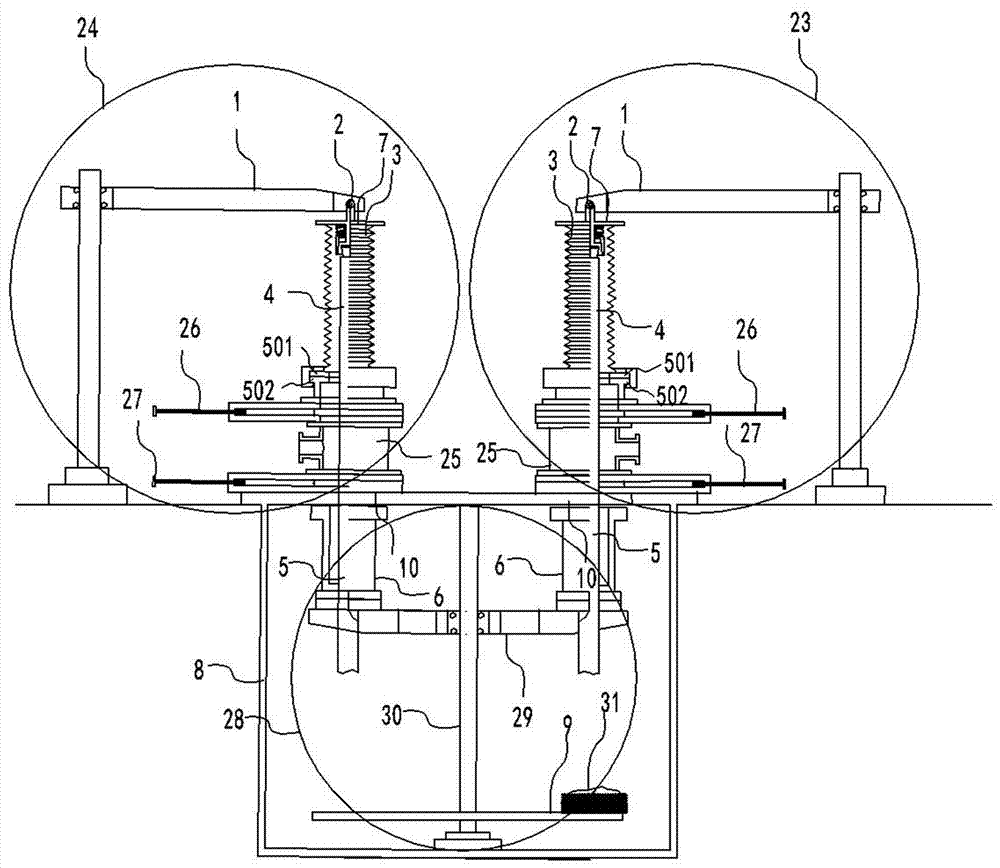

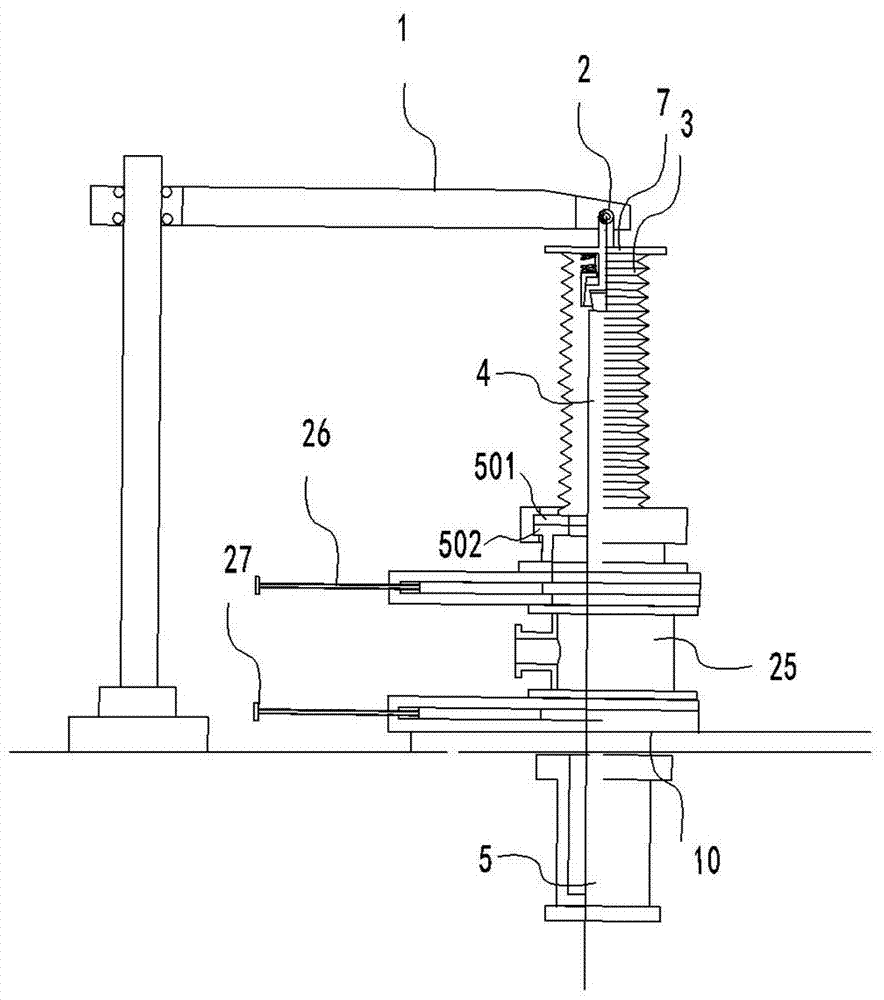

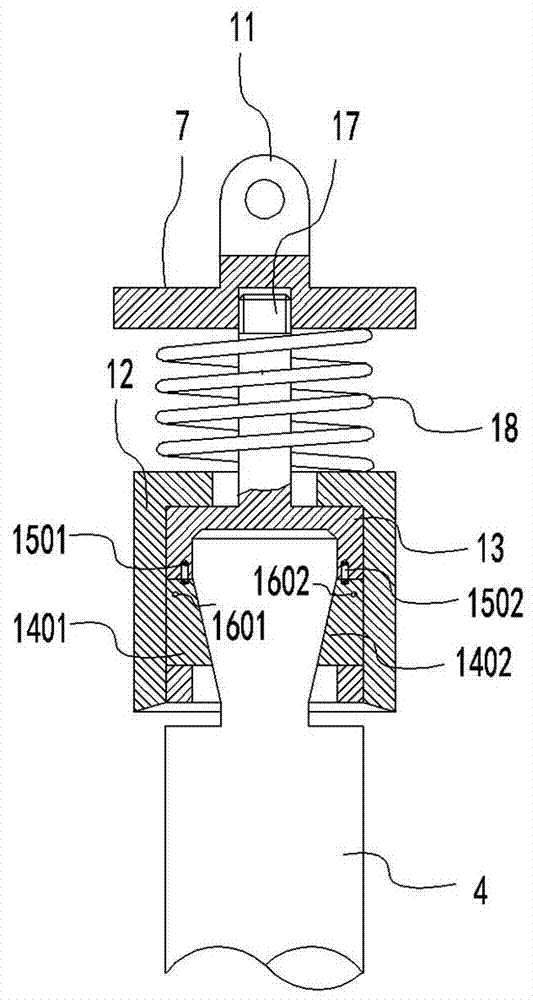

[0031] As shown in the figure, the double-station mobile crystallizer vacuum electroslag furnace includes the No. 1 station vacuum smelting unit 23 and the No. 2 station vacuum smelting unit 24 of the same structure; the No. 1 station vacuum smelting unit Unit 23 and No. 2 station vacuum melting unit 24 respectively include lifting arm 1, centering chuck 2, retractable sealing tube 3, dummy electrode 4, melting electrode 5, quick-release butt joint upper flange 501 and quick-release butt joint lower Flange 502; the top of the centering chuck 2 is hinged with the end of the lifting arm 1; the upper end of the telescopic sealing tube 3 is sealed with the baffle 7 of the centering chuck 2; the telescopic sealing tube The lower end of 3 is sealed with the quick-release docking flange 501; the upper end of the dummy electrode 4 is clamped with the centering chuck 2; the smelting electrode 5 is fixedly connected with the dummy electrode 4; the quick-release docking method The flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com