Novel prefabricated interior building wall and connecting structure of novel prefabricated interior building wall and adjacent floor slab

A connection structure and prefabricated technology, applied in building components, building structures, buildings, etc., can solve problems such as complex construction, low standardization, and large environmental impact, and achieve the goal of preventing water leakage or poor sound insulation, high standardization, and high standardization. Simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

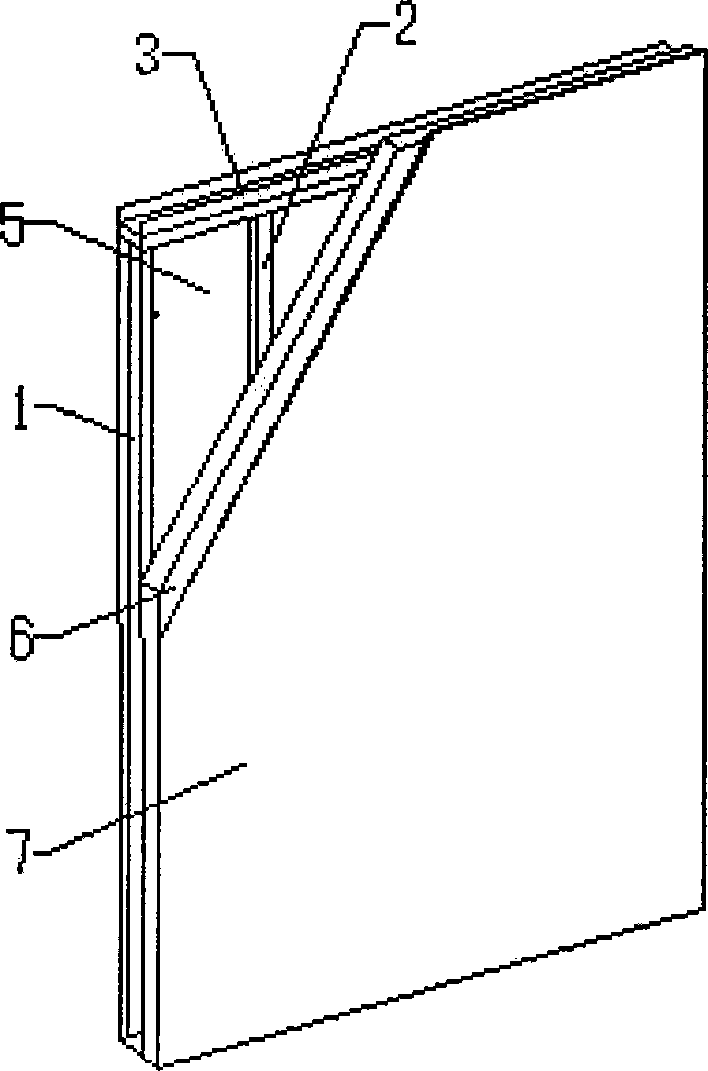

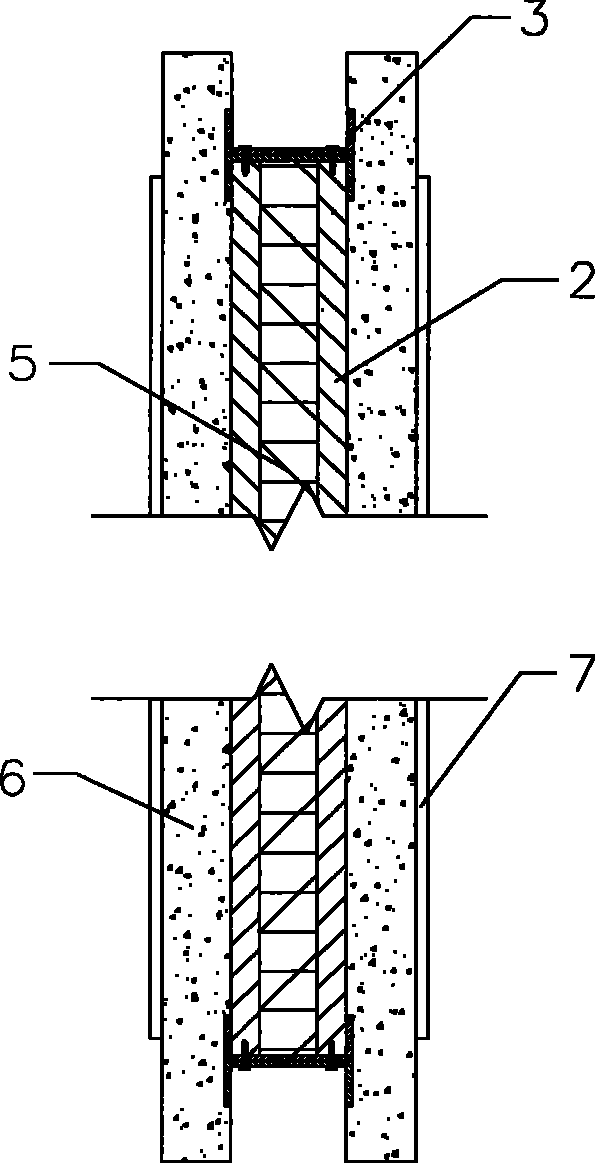

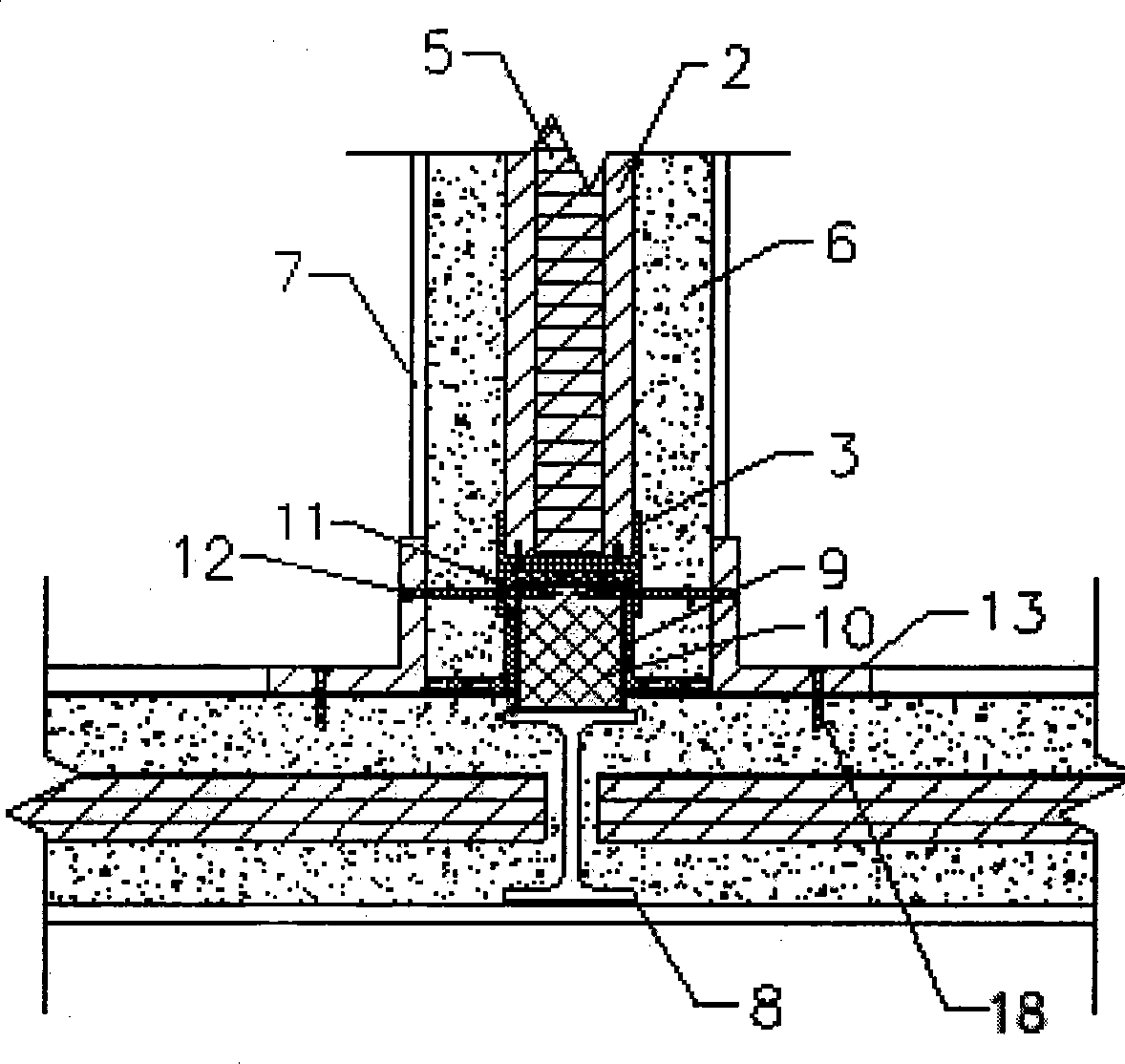

[0017] see Figure 1-3 , a new type of connection between a prefabricated non-load-bearing wall and an adjacent floor, including a butt wall and a floor, and the wall includes a horizontal cold-formed thin-walled channel steel keel 3 and a vertical cold-formed thin A skeleton frame composed of wall-shaped channel steel keels 1 welded to each other. The plane of the skeleton frame is a rectangular structure, and vertical cold-formed thin-walled crimped channel steel keels 2 are arranged in the internal gap. The vertical cold-formed thin-walled type The upper and lower ends of the rolled edge channel steel keel 2 are respectively vertically fixed on the inner side of the horizontal cold-formed thin-walled channel steel keel 3, and the space between the adjacent two vertical cold-formed thin-walled rolled edged channel steel keels 2 is filled with The polystyrene board 5 with the same width, the two sides of the grid type keel are filled with raw soil filling material 6, and the ...

Embodiment 2

[0023] (1) As for the prefabricated residence with layered wall panels, the one-piece floor should be put in place first;

[0024] (2) For the splicing of the floor slabs, after the floors on both sides are in place, the main channel steel girders are pasted together back to back, and then the channel steel connectors 16 are installed at the openings of the upper and lower flanges of the channel steel, and fixed with bolts 17 .

[0025] (3) Then arrange load-bearing walls with square steel pipe columns at corresponding positions;

[0026] (4) Then insert the non-load-bearing inner wall of the building from top to bottom at the position where the non-load-bearing wall is arranged;

[0027] (5) When inserting, lay some elastic caulking material 11 on the outside of the convex connection end of the lower floor, and make the concave connection end at the bottom of the inner wall of the building squeeze these filling materials, fully bite with the convex connection end, and form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com