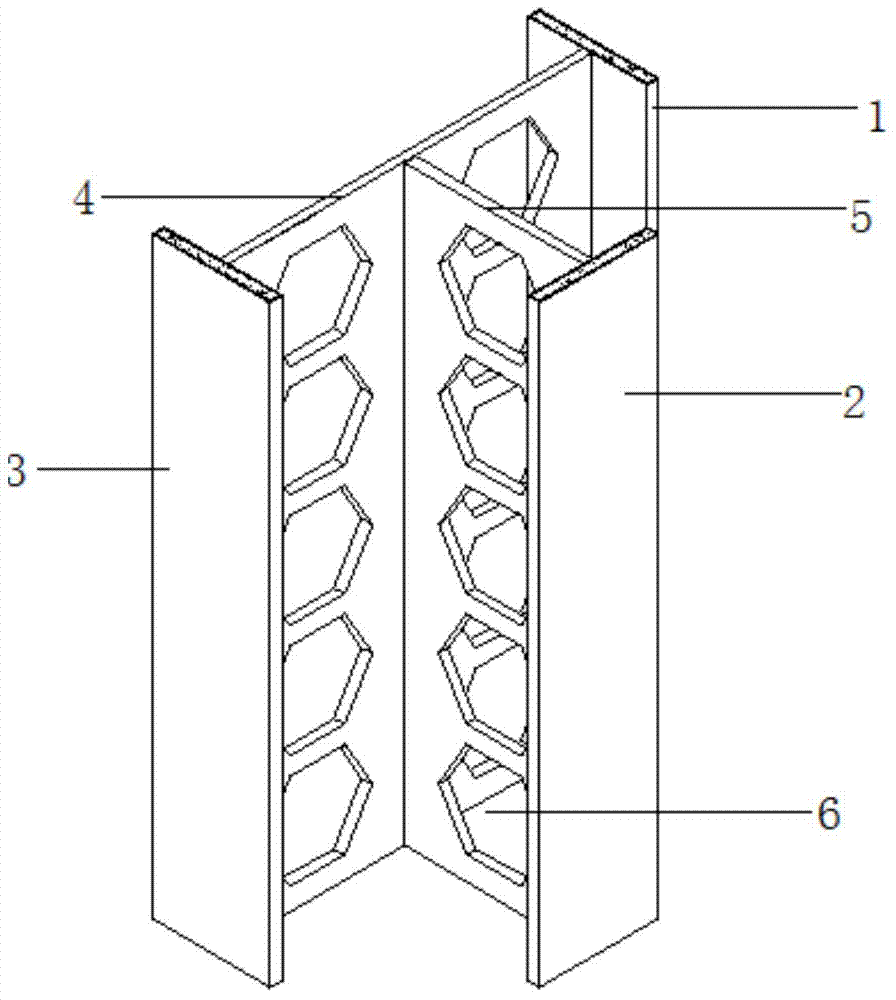

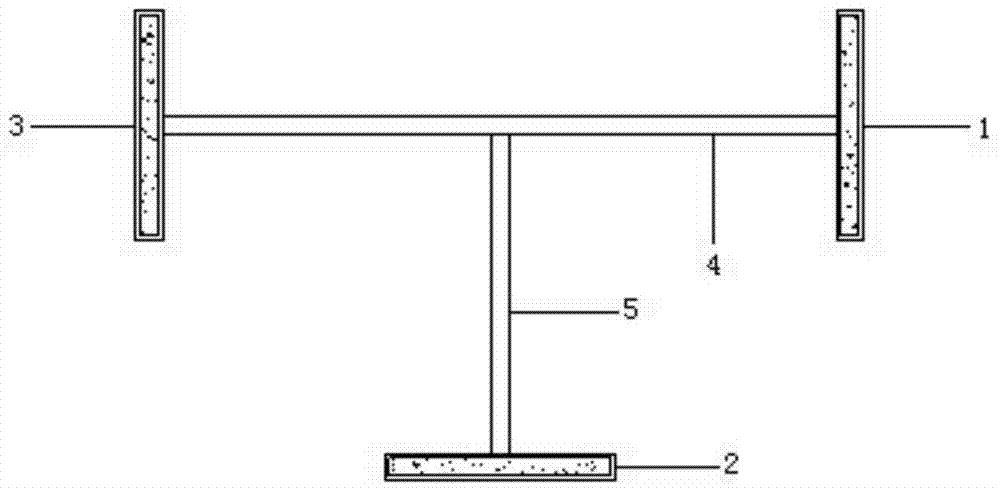

Honeycomb-shaped steel web and steel pipe concrete flange combined T-shaped section column

A technology of concrete filled steel tube and composite section, applied in the direction of columns, piers, pillars, etc., can solve the problems of increasing the comprehensive cost of the project, limited shear bearing capacity, and increased engineering costs, and achieves significant benefits and high shear bearing capacity. , the effect of reducing the weight of the structure

Inactive Publication Date: 2014-12-24

NANJING UNIV OF TECH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to meet the requirements of compressive bending mechanical performance, a larger section size is usually required. If a solid-web type T-shaped section special-shaped steel column is selected, the web shear strength will be much more abundant. However, in order to ensure the local stability of the web, it is necessary to meet the The web height-to-thickness ratio limit specified in the "Code for Design of Steel Structures" usually needs to increase the web thickness, which will lead to increased steel consumption and increased project costs, thereby increasing the overall cost of the project; if the truss type is selected T-shaped cross-section special-shaped steel columns, in addition to their limited shear bearing capacity, seismic performance and overall stability, the truss-type webs need to be welded with plates or strips, the construction is relatively cumbersome, and the connection workload is relatively large, which increases the Construction cost, which also increases the overall cost of the project

Moreover, when the bending moment effect is large, the flanges of the above two T-shaped special-shaped steel columns may enter the failure state prematurely, causing the steel columns to quickly lose their resistance; at the same time, the above two steel columns are all pure steel structure, its fire resistance is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0027] Usually the steel pipe, honeycomb steel web and its welding are completed in the factory; pouring concrete into the steel pipe is completed at the construction site.

[0028] The basic production procedure is: making honeycomb steel webs → making steel pipes → welding → transporting to the construction site → hoisting in place → pouring concrete into the steel pipes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a honeycomb-shaped steel web and steel pipe concrete flange combined T-shaped section column. The honeycomb-shaped steel web and steel pipe concrete flange combined T-shaped section column comprises a first steel pipe concrete flange, a second steel pipe concrete flange, a third steel pipe concrete flange, a first steel web, a second steel web and holes; one side edge of the second steel web is perpendicularly connected with the middle part of the first steel web and the other side edge of the second steel web and two side edges of the first steel web are respectively connected with the first steel pipe concrete flange, the second steel pipe concrete flange and the third steel pipe concrete flange together to form the special-shaped steel column with a T-shaped section; the first steel web and the second steel web are honeycomb-shaped webs of which the middles are provided with the holes; each of the first steel web and the second steel web respectively consists of steel plates of which the edges are provided with notches; the steel plates are welded by butt-jointed seams to form the honeycomb-shaped webs. According to the invention, the structural behavior is improved without obviously increasing comprehensive cost, so that the special-shaped column structure is more widely applied to multi-storey and high-rise residences.

Description

technical field [0001] The invention relates to the technical field of a novel building structure, in particular to a T-shaped column with a combined section of a honeycomb steel web-concrete steel tube flange. Background technique [0002] In residential buildings, special-shaped column structures have incomparable advantages over other structural systems, and are more and more favored by people. In recent years, they have been highly valued by scholars and engineers at home and abroad, and thus have been widely used. [0003] However, in multi-story residential buildings, the reinforced concrete special-shaped column structure is difficult to meet the bearing capacity requirements due to the limitation of the length and thickness ratio of the column section, the crowded reinforcement in the node area, and the unsatisfactory seismic performance and difficult to deal with. The advantages of the special-shaped column cannot be fully reflected, thereby limiting its application...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04C3/36

Inventor 郑廷银苏文邵连俊

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com