A tile laying machine

A laying machine and ceramic tile technology, which is applied in the direction of construction and building construction, can solve the problems of low adsorption stability of suction cups, high requirements for tiles, and tile throwing out, etc., to achieve automatic construction, wide variety, and fast laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

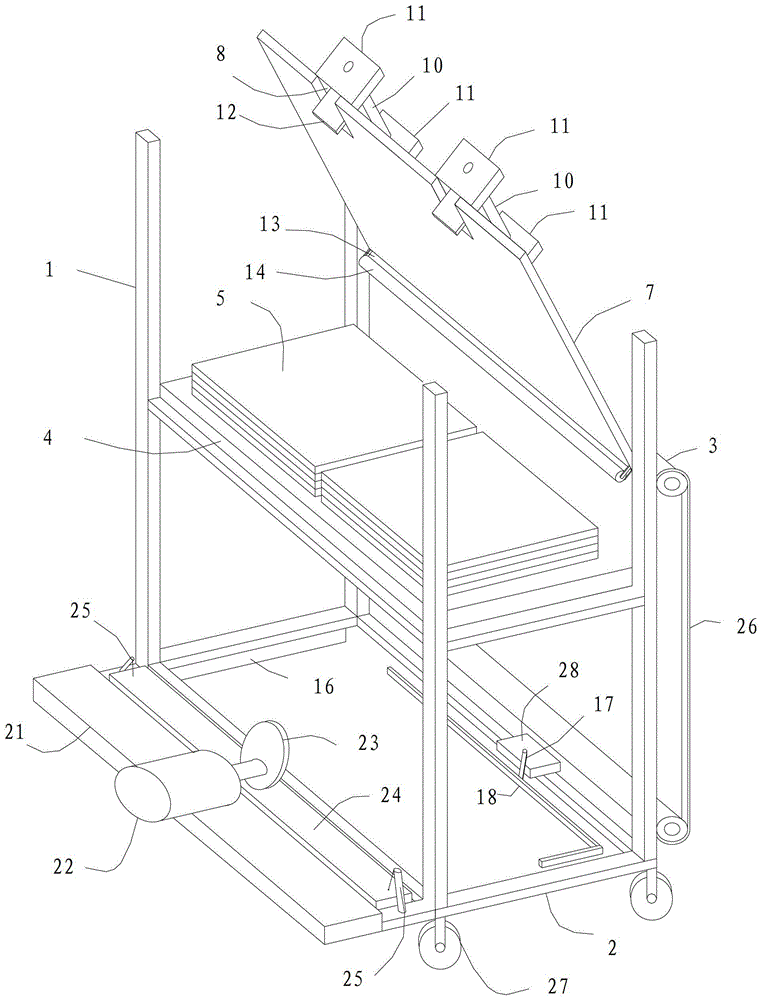

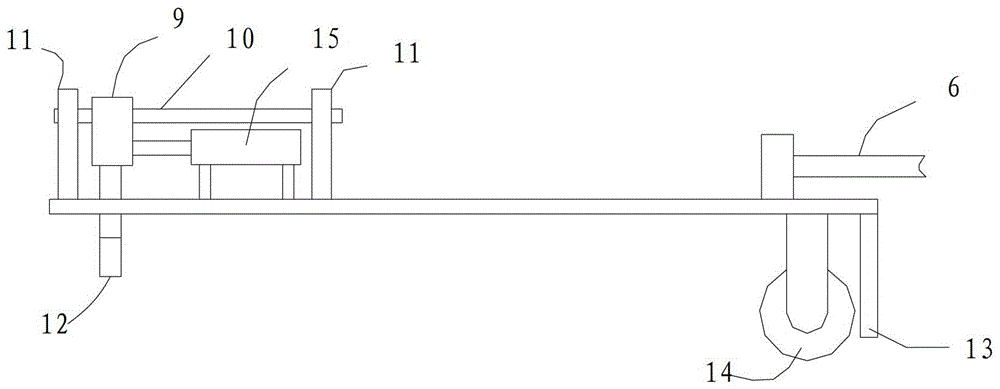

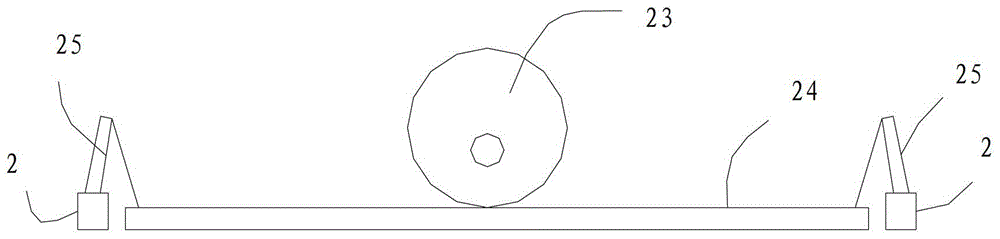

[0023] refer to Figure 1-3 , a tile laying machine, including a main frame 1 with wheels 27 at the bottom, a concrete slurry laying mechanism, a walking mechanism, etc. (not shown in the figure), wherein the upper part of the main frame 1 is provided with a tile placement platform 4 for placing tiles 5 , the bottom is provided with a construction frame 2 for laying tiles 5, and a lifting frame 3 is provided on one side of the main frame 1, and the lifting frame 3 is started by a sprocket 26, and moves up and down between the tile placement platform 4 and the construction frame 2. Lifting frame 3 is provided with rotating arm 6, and the free end of rotating arm 6 is fixed on one side of the upper surface of turning platform 7, and the other side of turning platform 7 is provided with the slot extending toward rotating arm 6 side direction. 8. Along the slot 8, a guide rail 10 fixed by the guide rail fixing seat 11 is provided on the upper surface of the turning table 7. The sl...

Embodiment 2

[0029] refer to Figure 4, is another kind of ceramic tile laying machine, and its difference from Embodiment 1 is that a flat push rod 19 and a flat push mechanism 20 are arranged on three adjacent sides of the construction frame 2, and the flat push rod 19 is connected to the flat push rod 19. Push the end of the mechanism 20. When flattening, the three horizontal pushing mechanisms 20 can simultaneously drive the horizontal pushing rods 19 to move inside the frame to squeeze and align the tiles, and can also drive the horizontal pushing rods 19 to move sequentially, which is suitable for more precise leveling and alignment requirements. Other technical features are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com