Choke manifold inclined hole cylinder valve core and valve seat adjustable throttle valve

A throttling manifold and adjustable technology, applied in sliding valves, valve devices, engine components, etc., can solve the problems of gate vibration, poor mutual cooperation performance, and difficult processing, and achieve high throttling accuracy and sealing performance. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

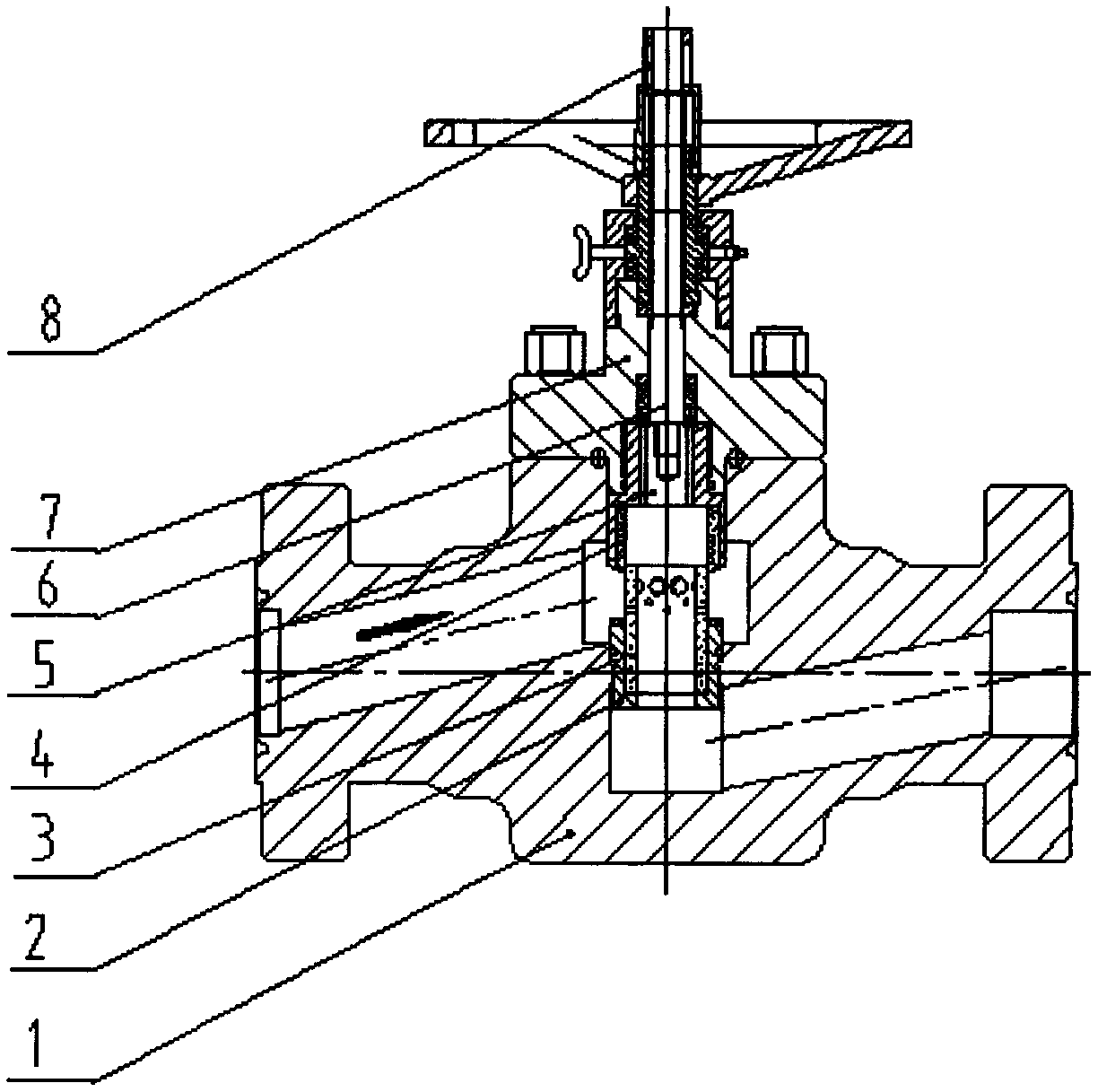

[0012] like figure 1 As shown, the choke manifold inclined hole cylindrical valve seat can be adjusted. There are three rows of throttle holes on the circumference of the valve seat of the throttle valve. Adjust the throttle aperture of the throttle valve seat to achieve the purpose of throttling. The choke manifold oblique hole cylindrical valve seat adjustable throttle valve includes a valve body 1, a valve seat cover 2, a valve seat 3, a valve core cover 4, a valve core 5, an adjustable valve stem 6, a valve cover 7 and an anti-corrosion valve. Dust cover 8, valve seat cover 2 and valve seat 3 are installed in valve body 1, valve core cover 4, valve core 5 and adjustable valve stem 6 are installed in valve body 1.

[0013] In the adjustable choke valve of the present invention with a slanted hole cylindrical valve core valve seat of the choke manifold, three rows of choke holes are arranged on the circumference of the valve seat 3 .

[0014] In the adjustable choke valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com