Pressure closed loop control digital integrated direct acting type proportional overflow valve

A proportional relief valve, closed-loop control technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve the problem that the performance and reliability of the proportional relief valve cannot meet the requirements of high-pressure and high-precision applications, and the regulating pressure is affected by overflow changes. The problems such as large influence of quantity and temperature, large valve pressure regulation deviation, etc., achieve the effect of high dynamic quality, small hysteresis, and reducing pressure regulation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

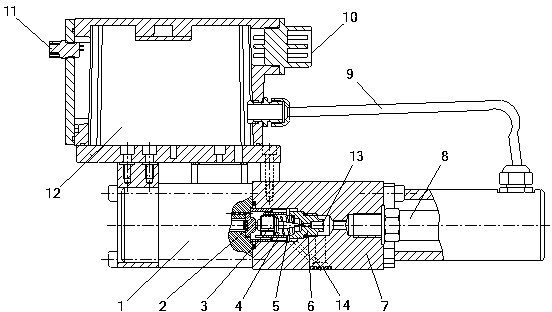

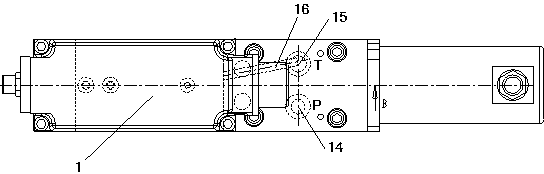

[0016] Such as figure 1 and figure 2 As shown, the pressure closed-loop control digital integrated direct-acting proportional relief valve of the present invention includes a valve core 3, a valve seat 6, a valve body 7, a proportional electromagnet 1, a pressure sensor 8 and a pressure closed-loop control digital integrated amplifier 12, The pressure closed-loop control digital integrated amplifier 12 is equipped with a communication interface 11 on one side and a seven-pin socket 10 on the other side. The valve core 3 is a cone valve core. Sensor 8, pressure closed-loop control digital integrated amplifier 12 is fixed on the proportional ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com