Range hood, panel assembly and front cover therefor, and method of making the same

A range hood and panel assembly technology, which is applied in the direction of oil fume removal, lighting and heating equipment, application, etc., can solve the problems of needing welding and increasing product manufacturing costs, and achieve the effects of reducing preparation costs, convenient preparation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

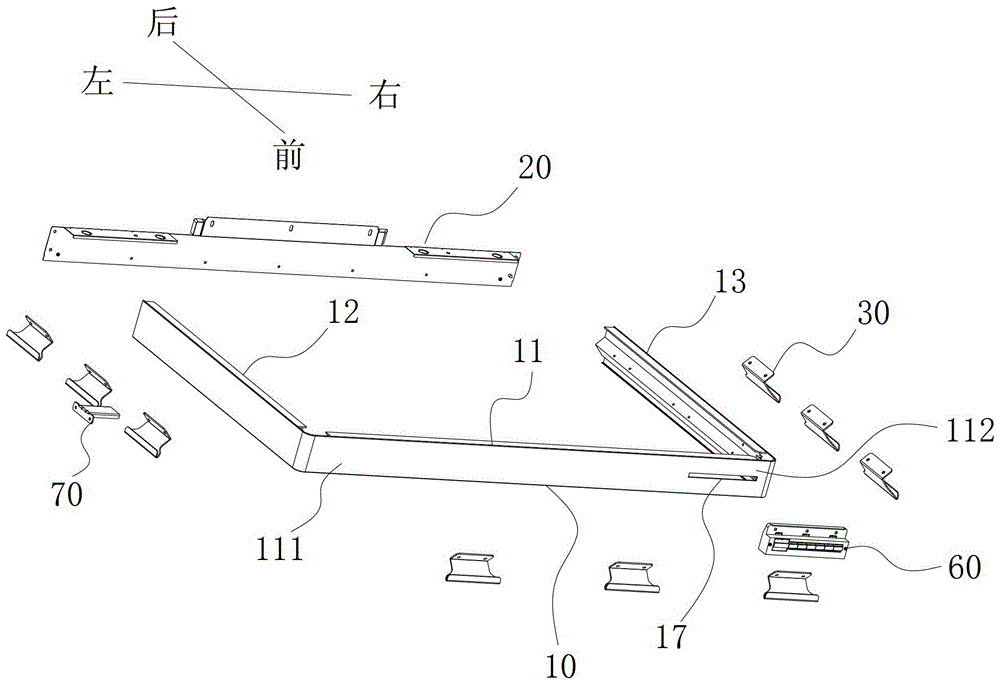

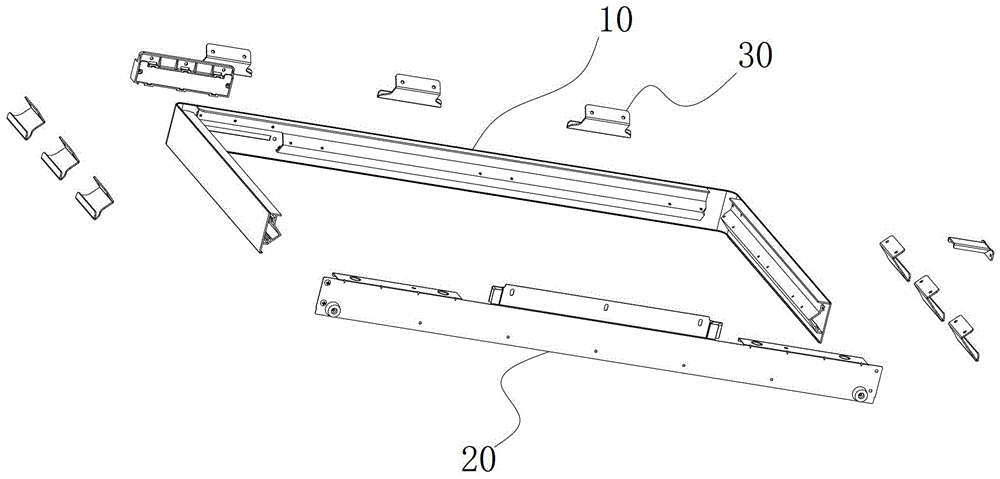

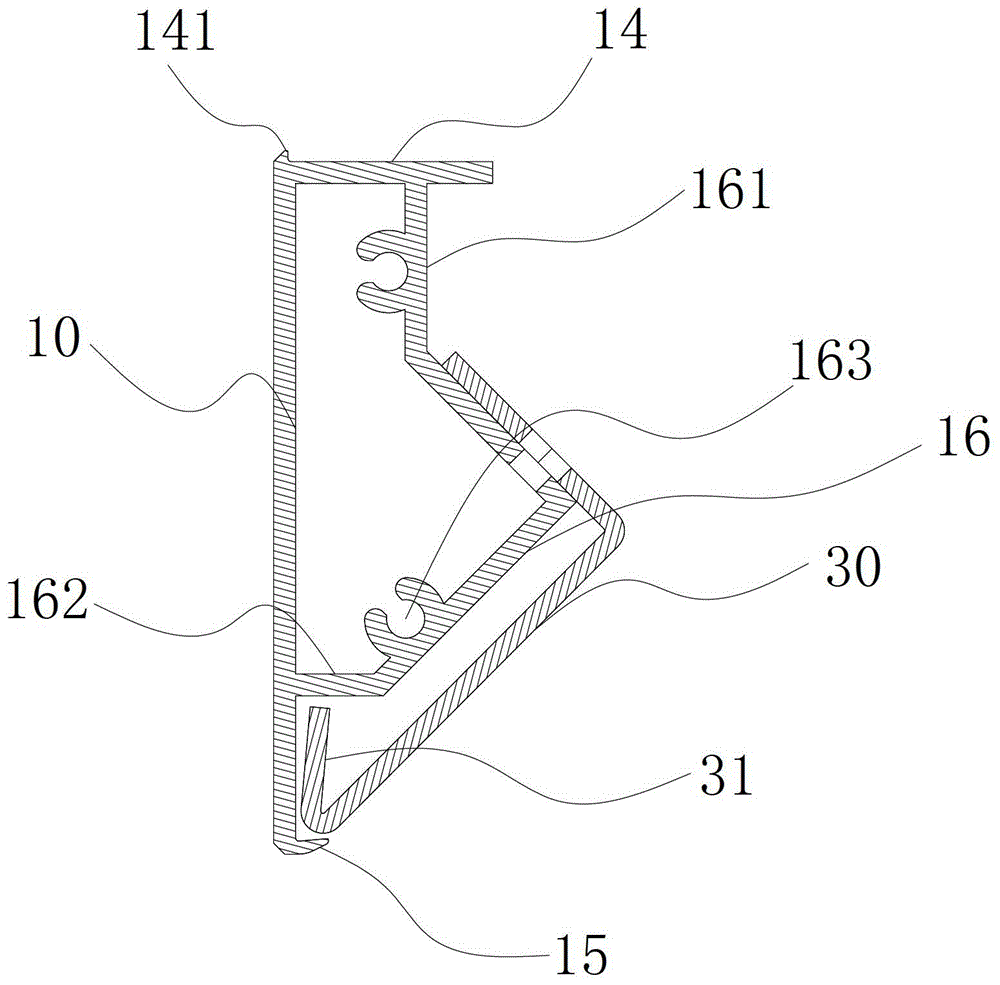

[0060] Specifically, the preparation method of the front cover according to the embodiment of the present invention includes the following steps:

[0061] S1: Extrude a strip-shaped aluminum profile, the upper edge of the strip-shaped aluminum profile forms a top plate installation part, the lower edge of the aluminum profile forms a smoke collection chamber installation part, the top plate installation part and the smoke collection chamber A bracket fixing part is formed between the mounting parts;

[0062] S2: forming a thin plate structure at the intended bending position of the strip-shaped aluminum profile; and

[0063] S3: Bending the strip-shaped aluminum profile into a predetermined shape from the intended bending position to obtain the front cover.

[0064] Wherein, the front cover 10 according to the embodiment of the present invention is the front cover 10 in the panel assembly for the range hood of the above-mentioned embodiments of the present invention. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com