Electronic gauge for automatically detecting vehicle sunroof assembly glass

An automobile sunroof, automatic detection technology, applied in the direction of measuring devices, instruments, etc., can solve the problem of automatic detection of automobile sunroof glass, etc., to avoid errors, avoid manual positioning, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

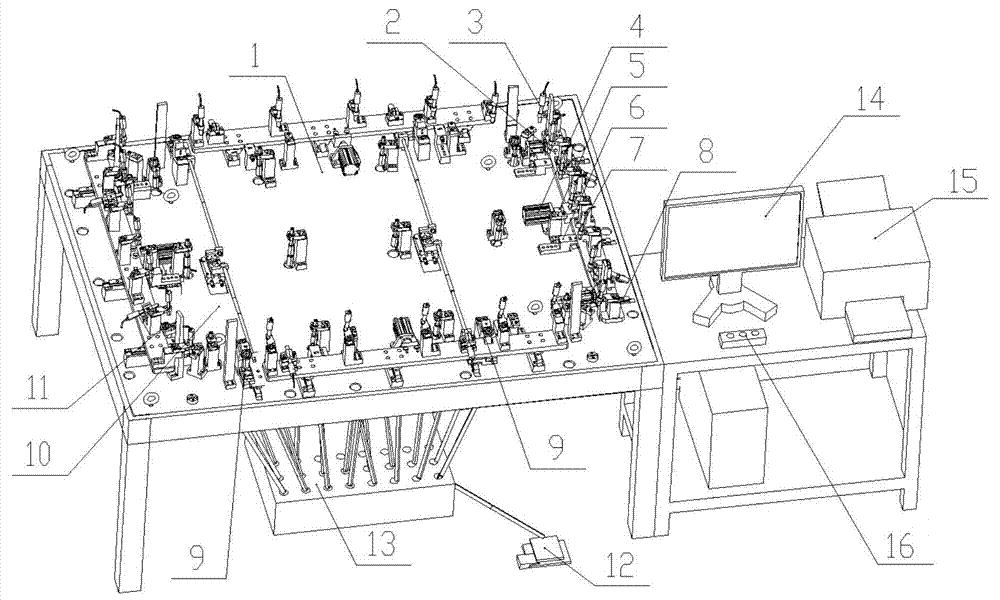

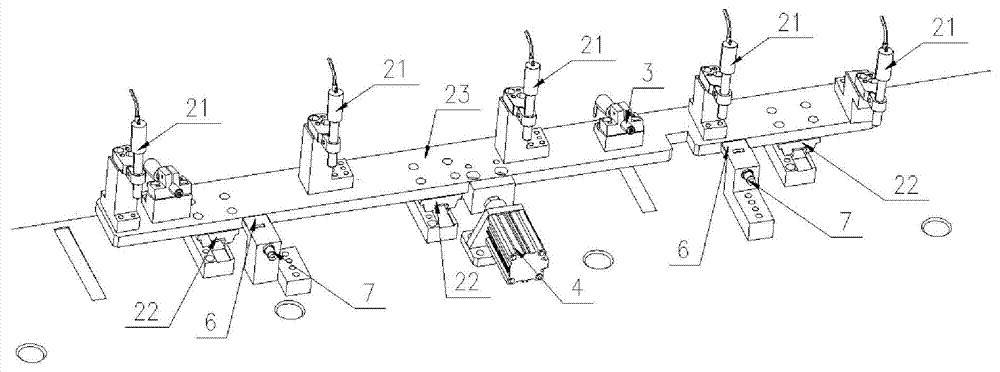

[0024] An electronic inspection tool for automatic detection of glass in an automobile sunroof assembly, the structure of which is as follows: figure 1 As shown, it mainly includes a computer 14, a foot valve 12, a cast aluminum base plate 1, and a centering mechanism 9 installed on the cast aluminum base plate 1, a clamping positioning block 11, a slide plate mechanism 2, a buffer 7, a limit block 6, The electronic sensor 3, the foot valve 12 are connected to the air source, and the centering mechanism 9 and the slide plate mechanism 2 are controlled to be loosened and put into the car sunroof assembly glass 10 to be tested, and then the centering mechanism 9 is controlled to be closed by the foot valve 12 and clamped. Tighten the positioning block 11 to clamp the limit, the slide plate mechanism 2, driven by the cylinder 4, slowly closes to the limit block 6 through the buffer 7 to complete the positioning, and the electronic sensor 3 contacts and senses that the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com