Machine vision detection mechanism for standard fasteners

A technology for machine vision inspection and standard fasteners, which is applied in the direction of instruments, measuring devices, and optical testing for flaws/defects. The effect of high degree of automation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

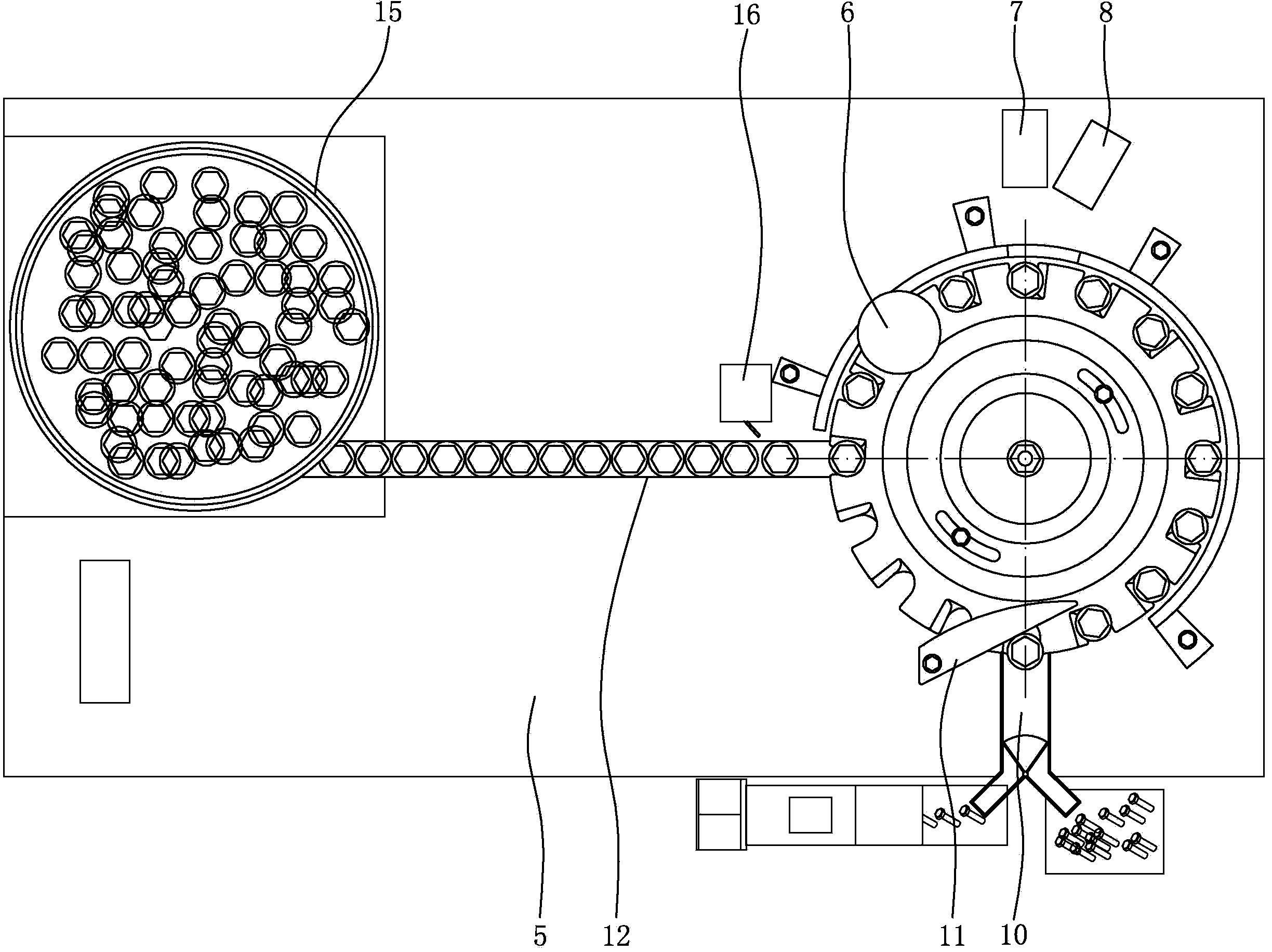

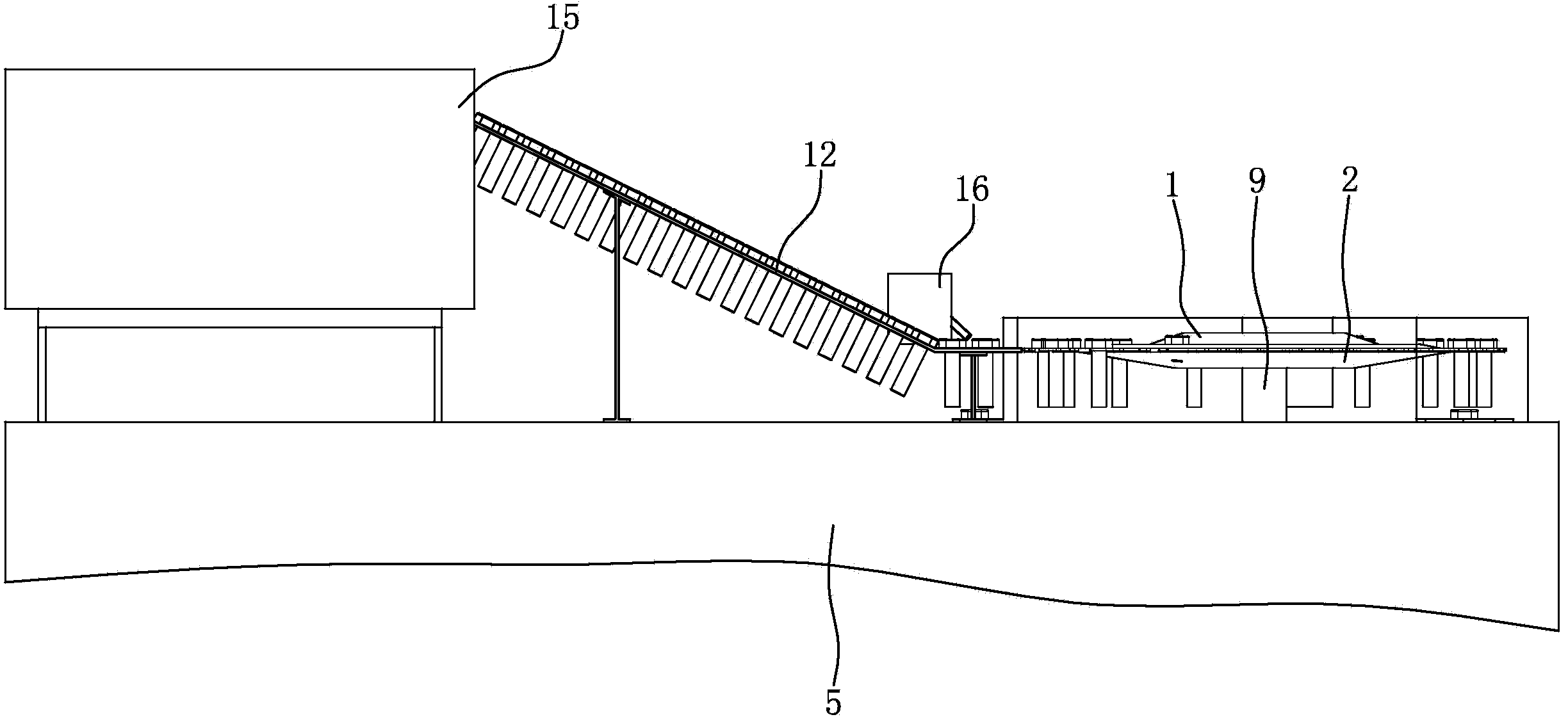

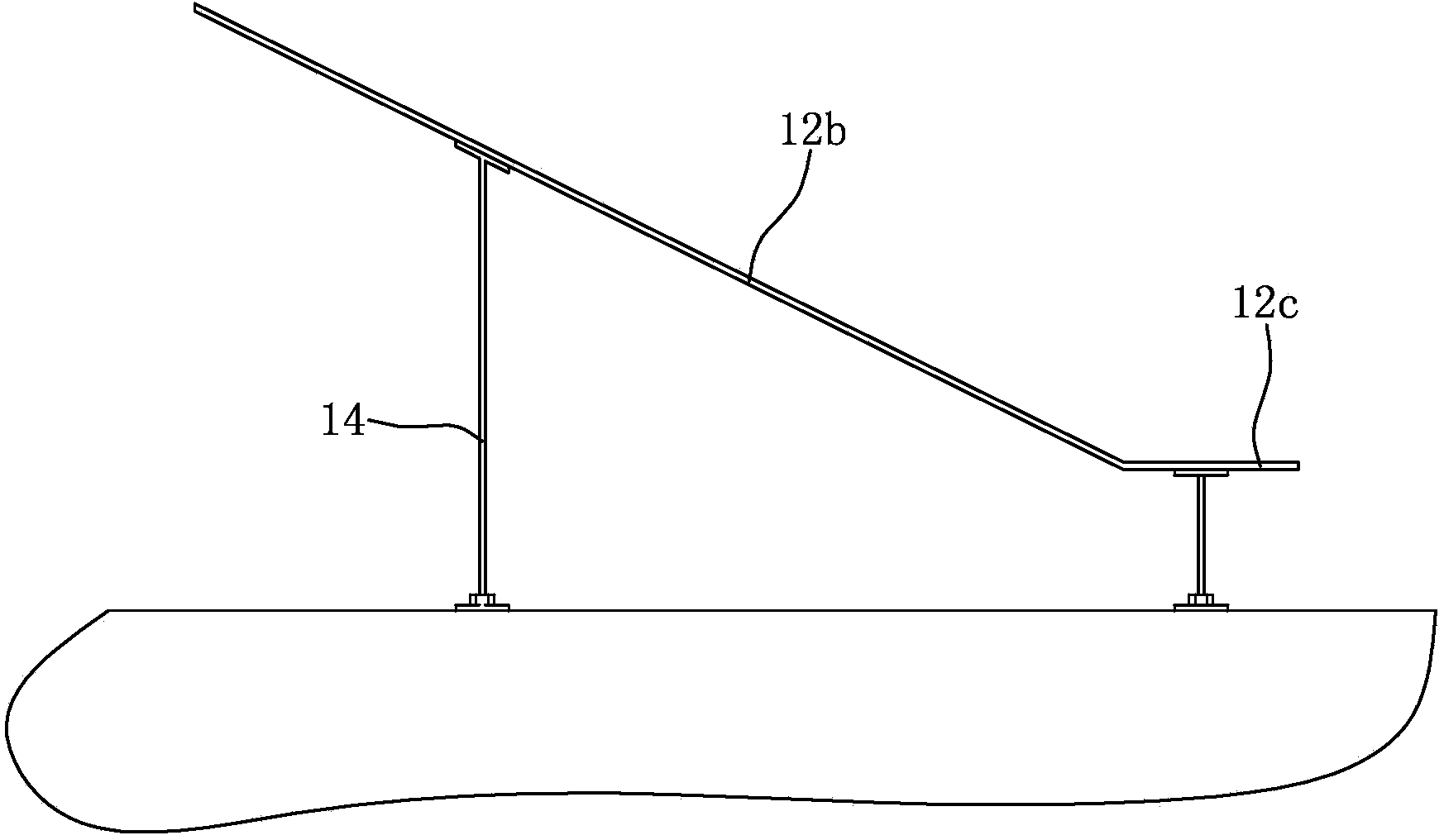

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0035] Such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a vibrating plate 15 is installed at one end of the top of the machine table 5, and the vibrating plate 15 is driven by a vibrating motor. The other end of the top of the machine platform 5 is provided with an indexing turntable, which is arranged on the machine platform 5 and consists of a moving plate 1 and a fixed plate 2 . The moving plate 1 and the fixed plate 2 are disc structures with equal diameters, and the moving plate 1 is located directly above the fixed plate 2 . The middle part of the top surface of the moving disk 1 is integrally formed with a stepped boss with a small upper part and a larger lower part; The surfaces are fitted together, and the moving plate 1 and the fixed plate 2 are connected by two fastening bolts evenly distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com