Patents

Literature

31 results about "Three-CCD camera" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A three-CCD (3CCD) camera is a camera whose imaging system uses three separate charge-coupled devices (CCDs), each one receiving filtered red, green, or blue color ranges. Light coming in from the lens is split by a complex prism into three beams, which are then filtered to produce colored light in three color ranges or "bands". The system is employed by high quality still cameras, telecine systems, professional video cameras and some prosumer video cameras.

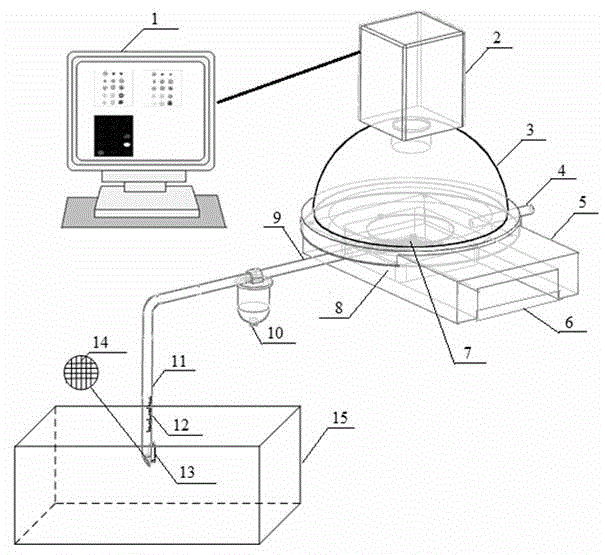

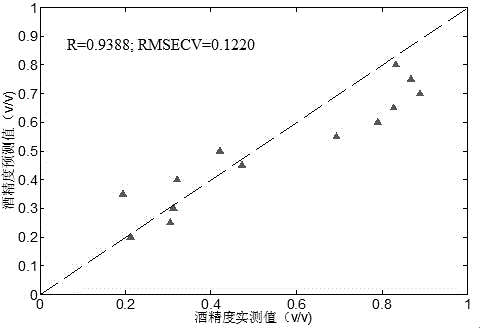

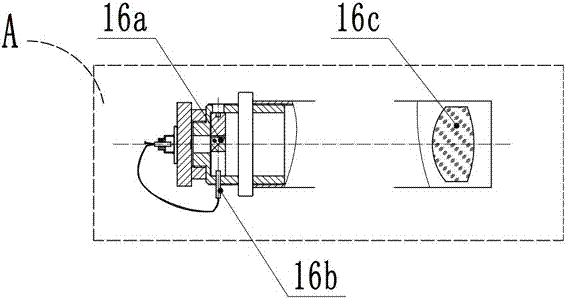

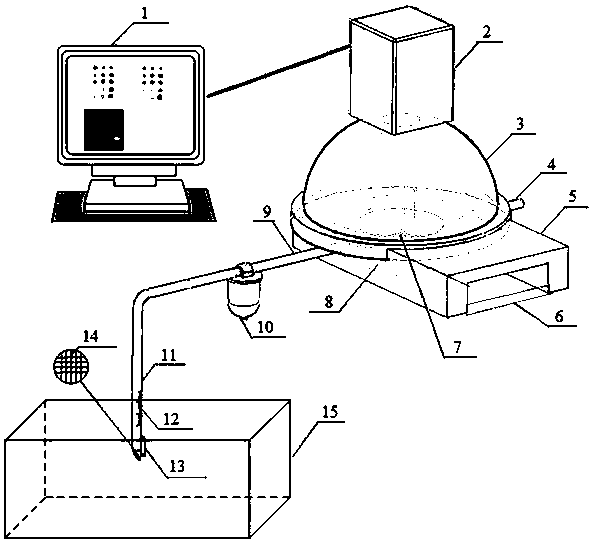

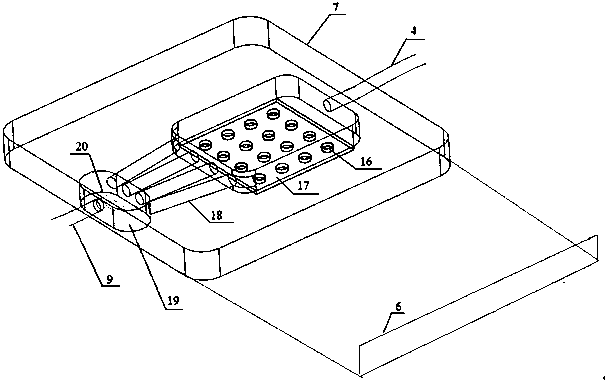

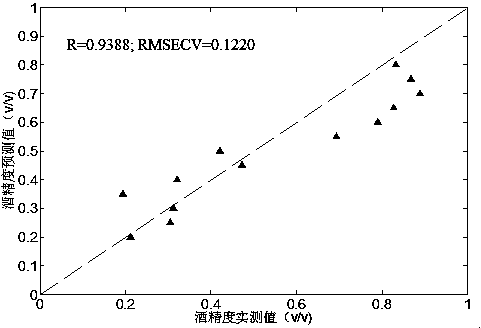

Novel alcohol degree detection method and apparatus

ActiveCN104977296AIncrease softnessSimplify the detection and analysis processMaterial analysis by observing effect on chemical indicatorEngineeringColor changes

The invention relates to a novel alcohol degree detection method and apparatus, especially relates to an detection method and apparatus based on a color sensitive material, wherein the detection method and apparatus are used to detect the alcohol degree during the fermentation process in real time, and belongs to the fields of fermented product raw material utilization and quality control. The apparatus comprises an upper computer, three CCD cameras, a LED integrating sphere light source, a base, a gas reaction chamber, an air inlet, an air outlet, a vacuum pump, a gas collecting probe with a special filter screen, and a temperature sensor. After the gas collected by the gas colleting probe reaches the gas reaction chamber, the gas reacts with the color sensitive material sensor arrays, which are adhered on the polyvinylidene difluoride membrane in the array area of a gas sensor; the color sensitive material is sensitive to alcohol, and thus the alcohol degree can be determined by watching the color change after the color sensitive material reacts with ethanol. The provided method and apparatus has the advantages that the operation is simple and convenient, the method is intelligent; the apparatus is simplified and is convenient to move; at the same time the detection system cost is reduced; and furthermore, the provided apparatus can be used to detect liquid alcohol and semi-solid alcohol.

Owner:JIANGSU UNIV

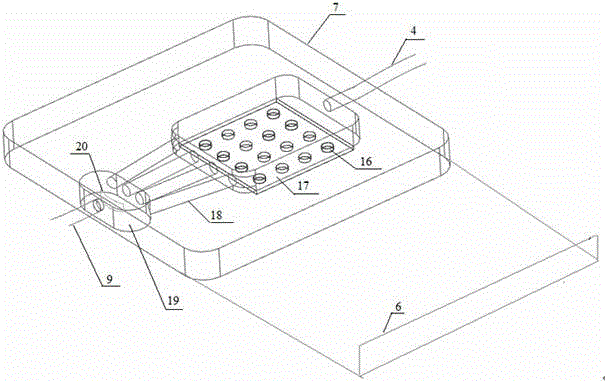

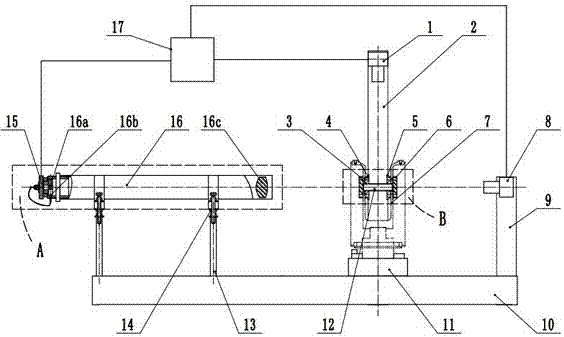

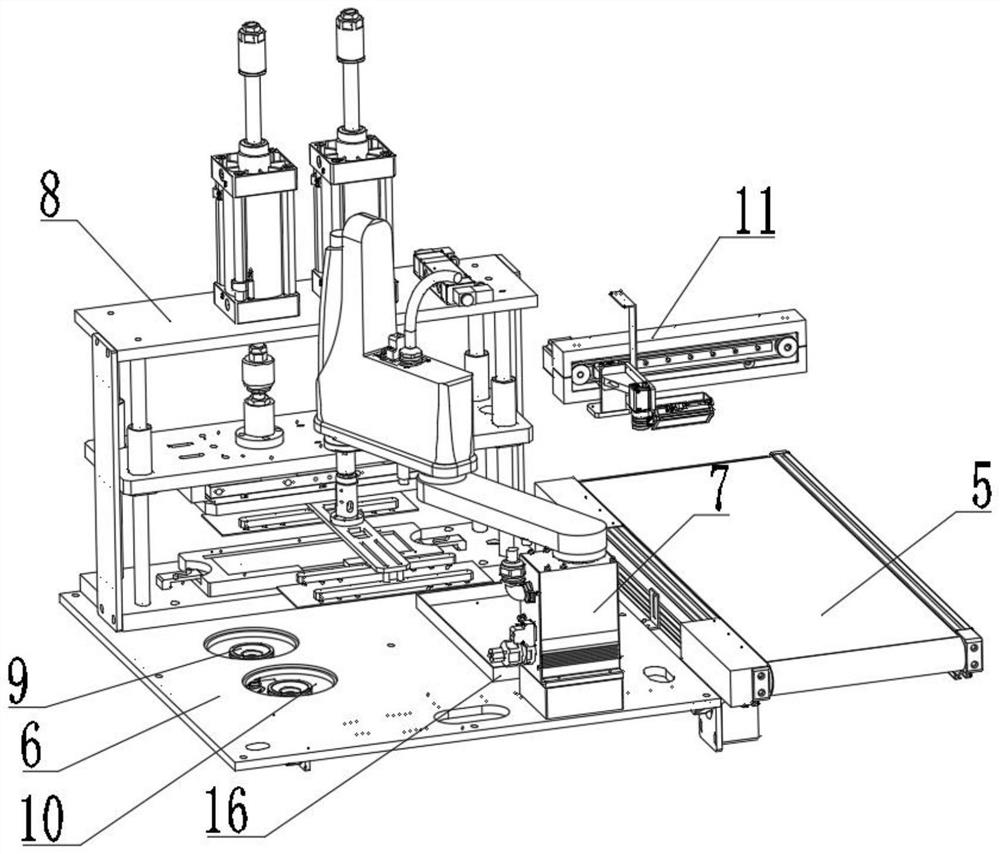

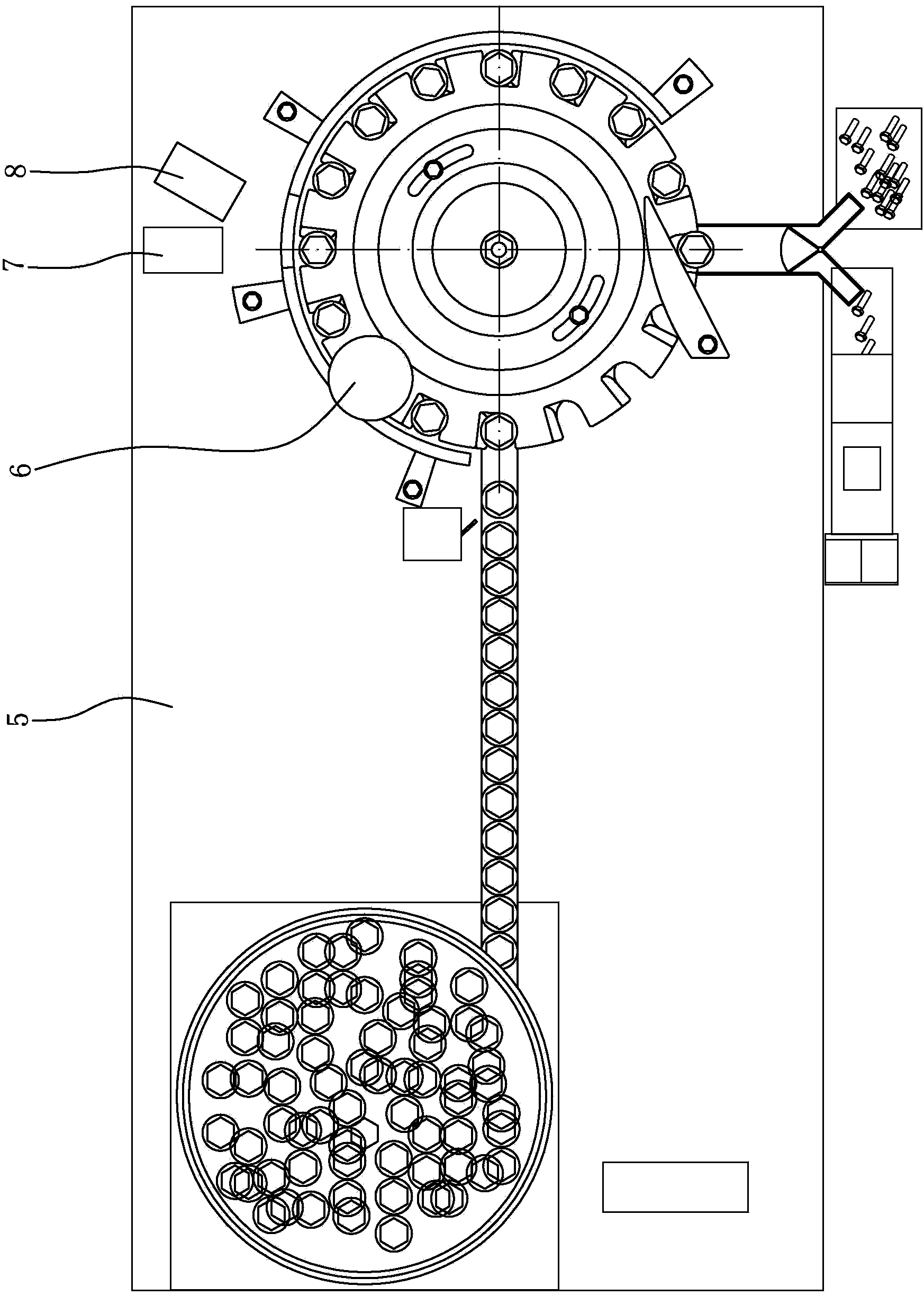

Machine vision detection system for standard fasteners

InactiveCN104142331AWon't shakeImprove stabilityOptically investigating flaws/contaminationUsing optical meansMachine visionEngineering

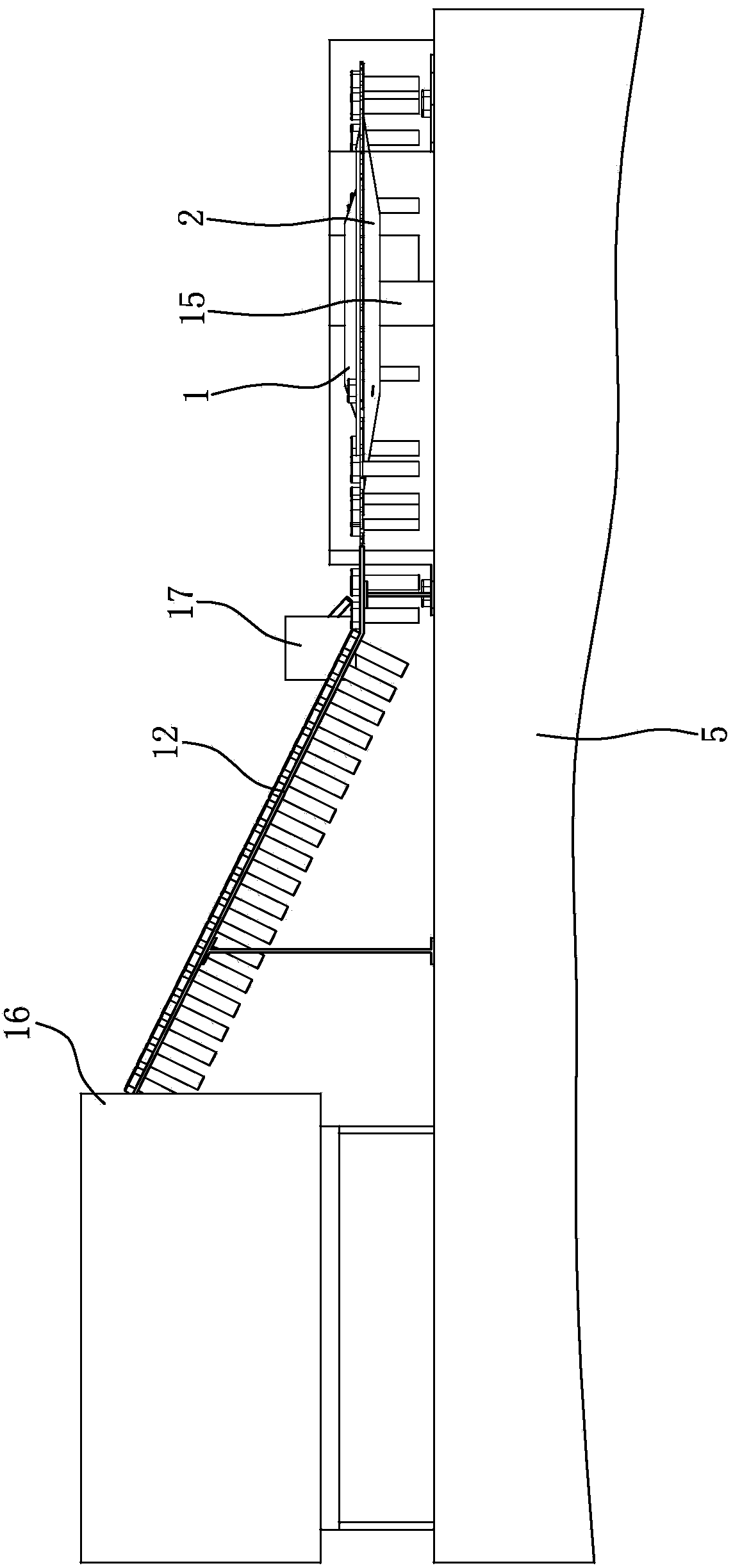

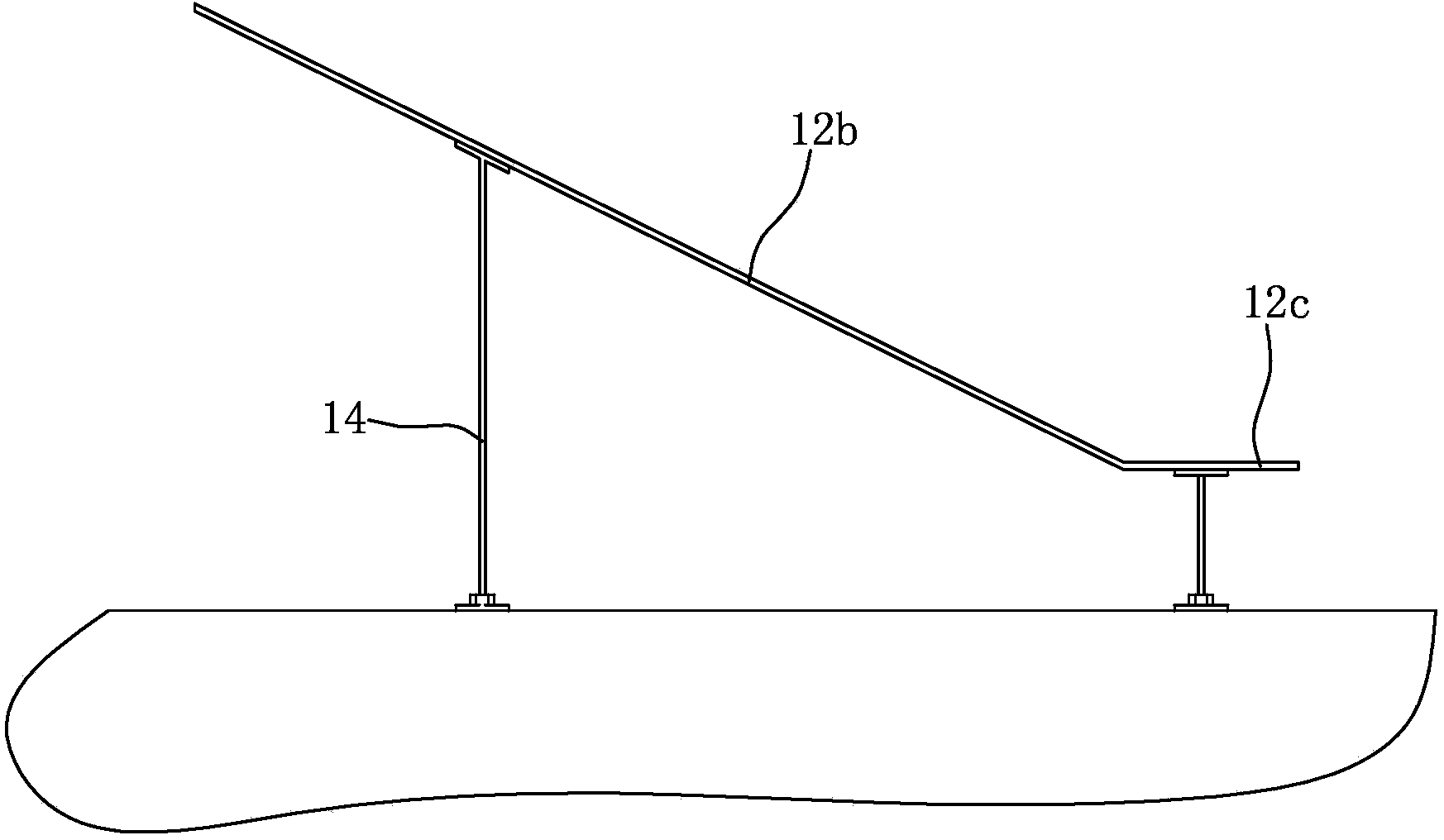

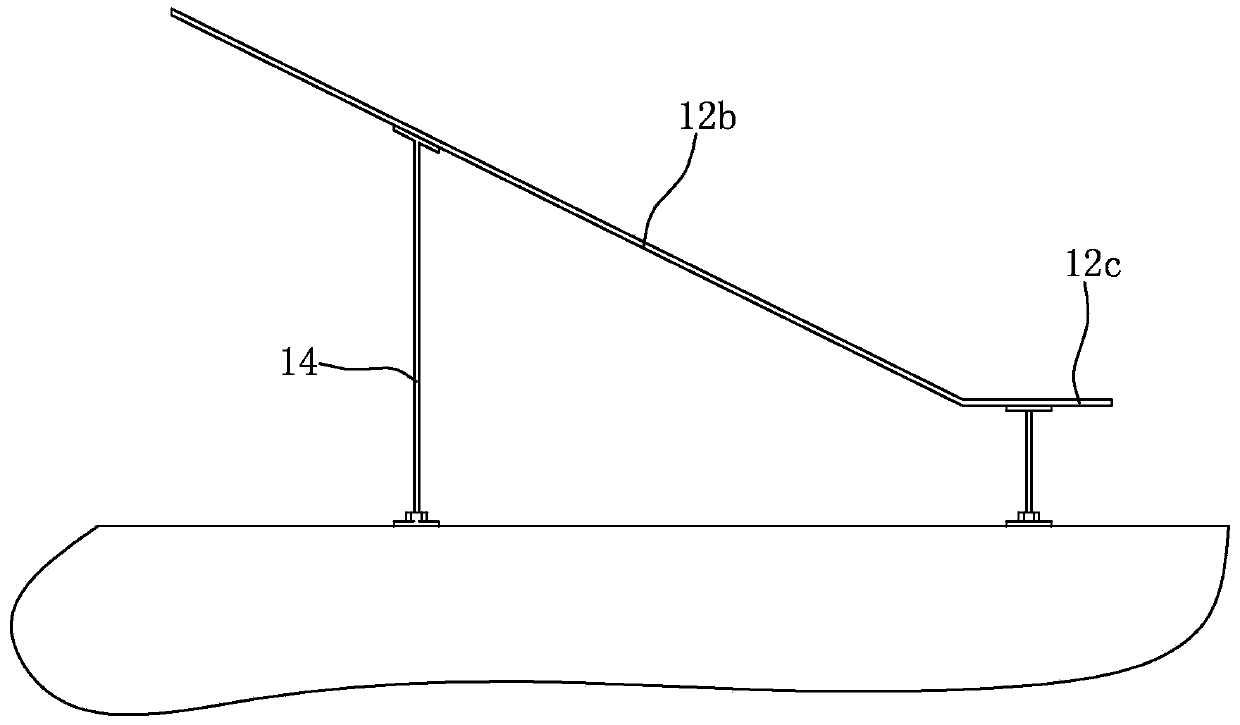

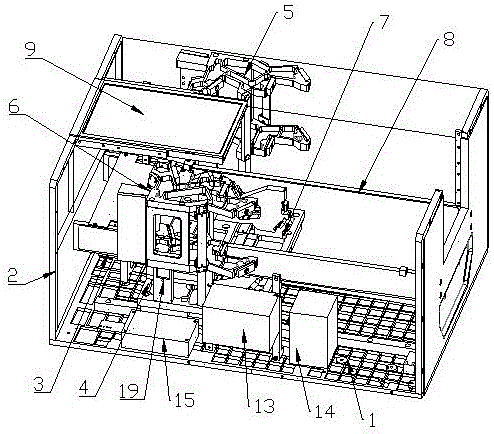

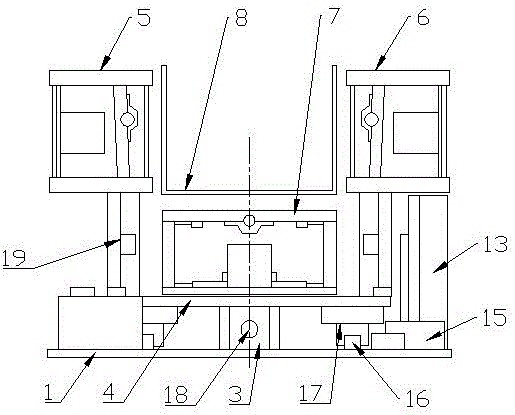

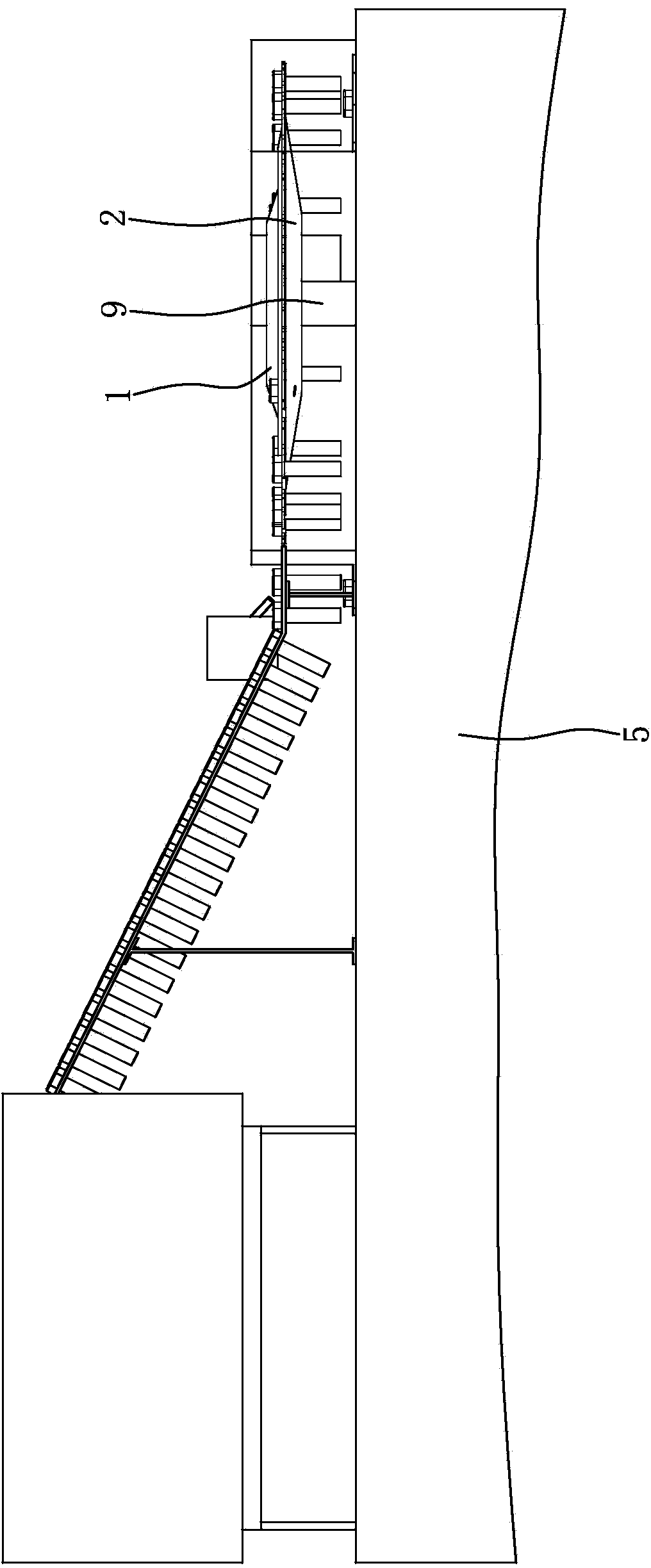

The invention discloses a machine vision detection system for standard fasteners. A vibration disc (16) is arranged at one end of the top of a machine table (5), a scale division rotating disc is arranged at the other end of the top of the machine table (5), a guide rail (12) for conveying parts is arranged between the vibration disc (16) and the scale division rotating disc, the guide rail (12) is composed of a fixed conveying rail (12a) and an adjustable conveying rail (12b), and the fixed conveying rail (12a) and the adjustable conveying rail (12b) are arranged side by side. An anti-falling-off baffle (9) is arranged on the periphery of the scale division rotating disc in a semi-surrounding mode, and a sliding way (10) for bearing the parts is arranged beside the scale division rotating disc. Pictures of the parts are shot by three CCD cameras from different angles, conveying, detection, sorting and packaging of the standard fasteners can be completed automatically, the system can be used for detecting various standard fasteners, the system can prevent the standard fasteners from falling off, and meanwhile the system can adapt to to-be-detected parts of different specifications. The machine vision detection system is good in generality, high in automation degree and high in detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

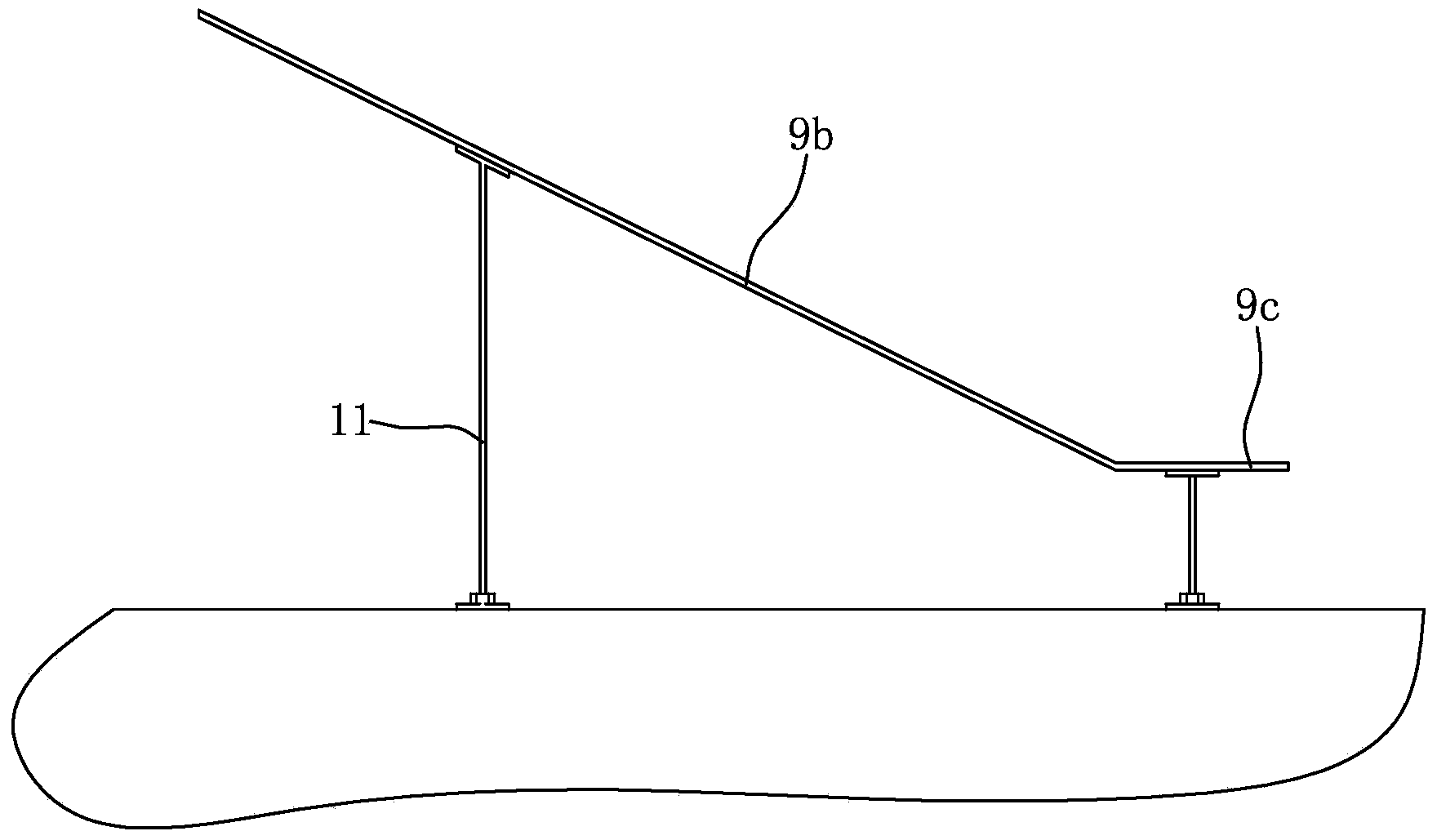

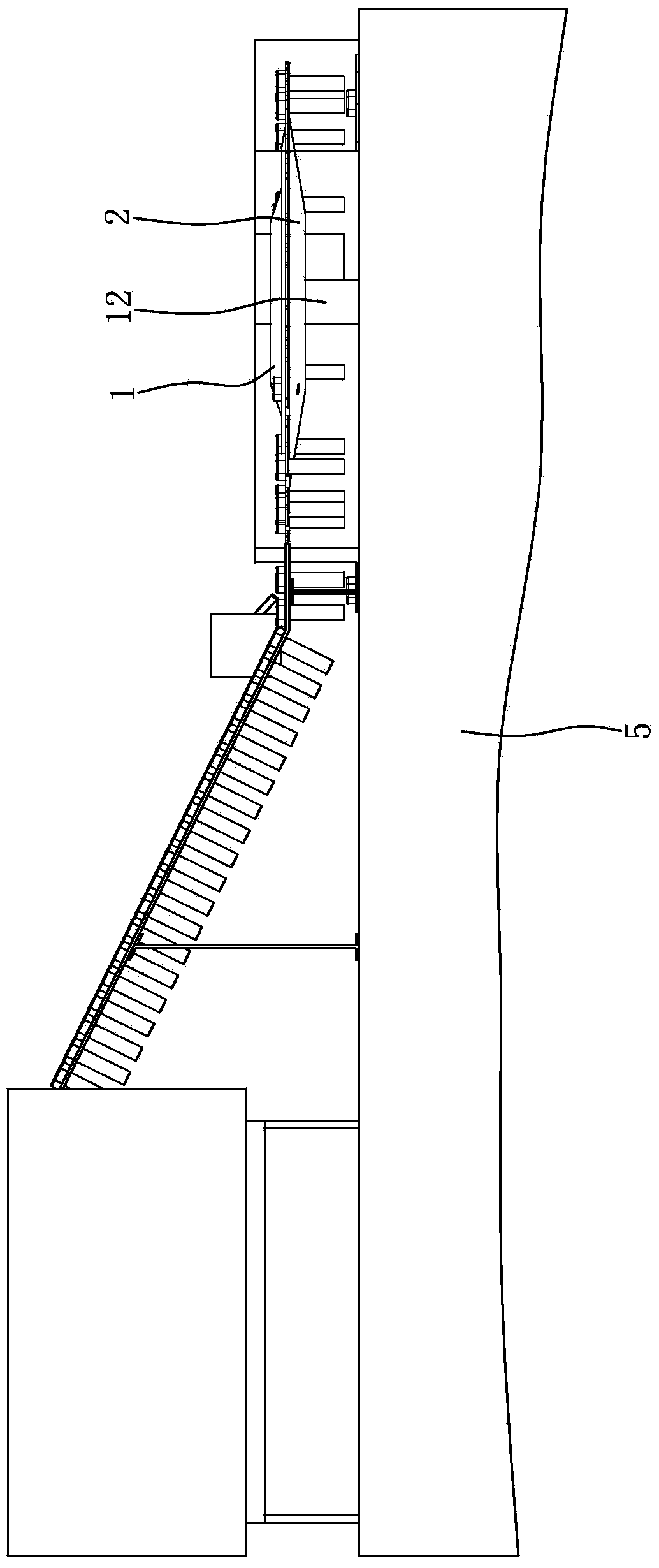

Plant protection system and plant protection method on basis of visible light-infrared technologies for trees

ActiveCN107593200AImprove controllabilitySave human effortMaterial analysis by optical meansPressurised distribution of liquid fertiliserEngineeringCcd camera

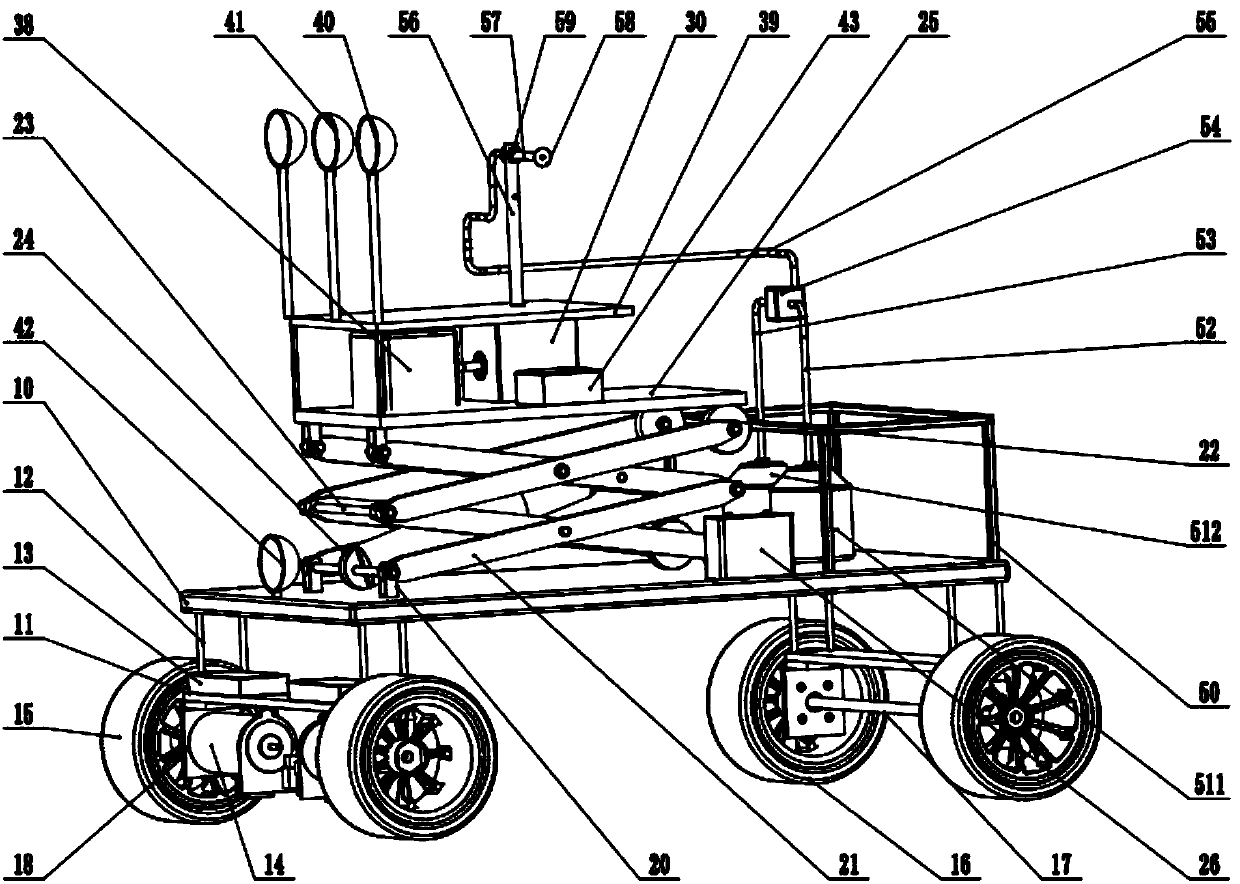

The invention relates to a plant protection system and a plant protection method on the basis of visible light-infrared technologies for trees. The plant protection system is characterized by comprising an advancing device, a lifting device, a speed reduction rotary device, an image acquiring and processing device and a medicine administration device; the lifting device, the speed reduction rotarydevice, the image acquiring and processing device and the medicine administration device are carried by the advancing device, and travel power can be provided by the advancing device; the image acquiring and processing device comprises a single chip microcomputer processor, three CCD (charge coupled device) cameras and an infrared camera, the infrared camera is used for detecting leaves to determine whether insects are available on the leaves or not, two of the three CCD cameras are used for binocular recognition calibration, and the other CCD camera is used for vision tracking; the two CCD cameras for binocular recognition calibration are fixed onto the upper surface of the lifting device by the aid of a pair of binocular camera frameworks, and the infrared camera is fixed onto the lifting device by the aid of an infrared camera framework and is positioned between the pair of binocular camera frameworks. The plant protection system and the plant protection method have the advantagesthat focuses of the trees can be recognized, and medicines can be administrated at fixed points according to the types of the focuses.

Owner:HEBEI UNIV OF TECH

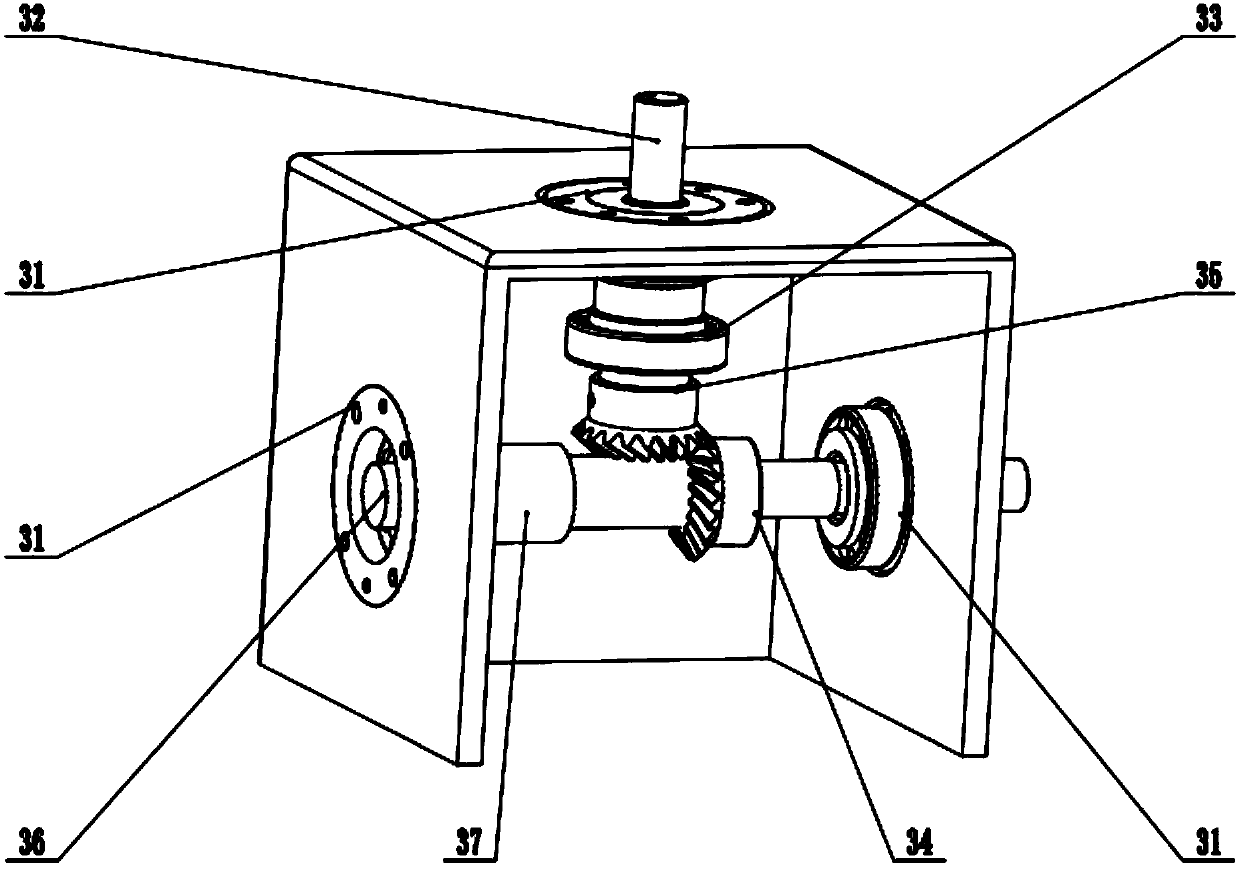

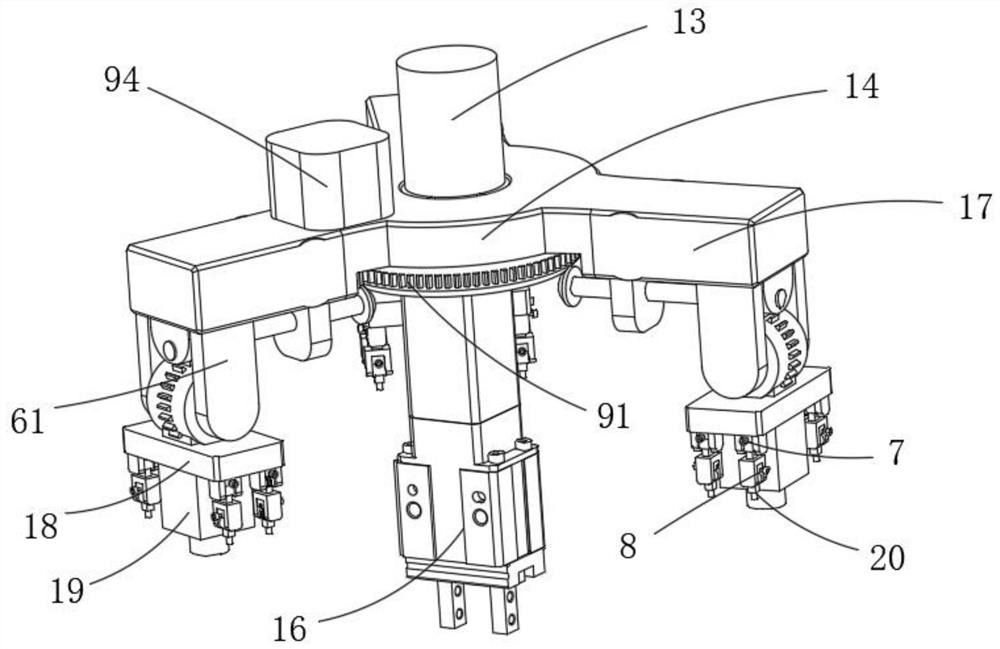

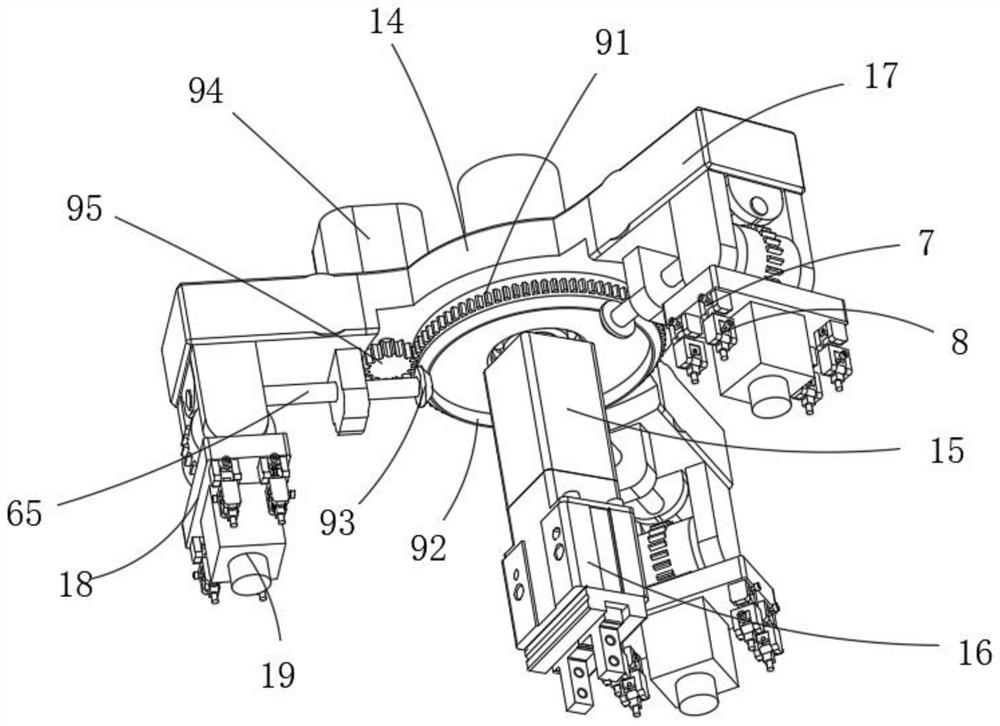

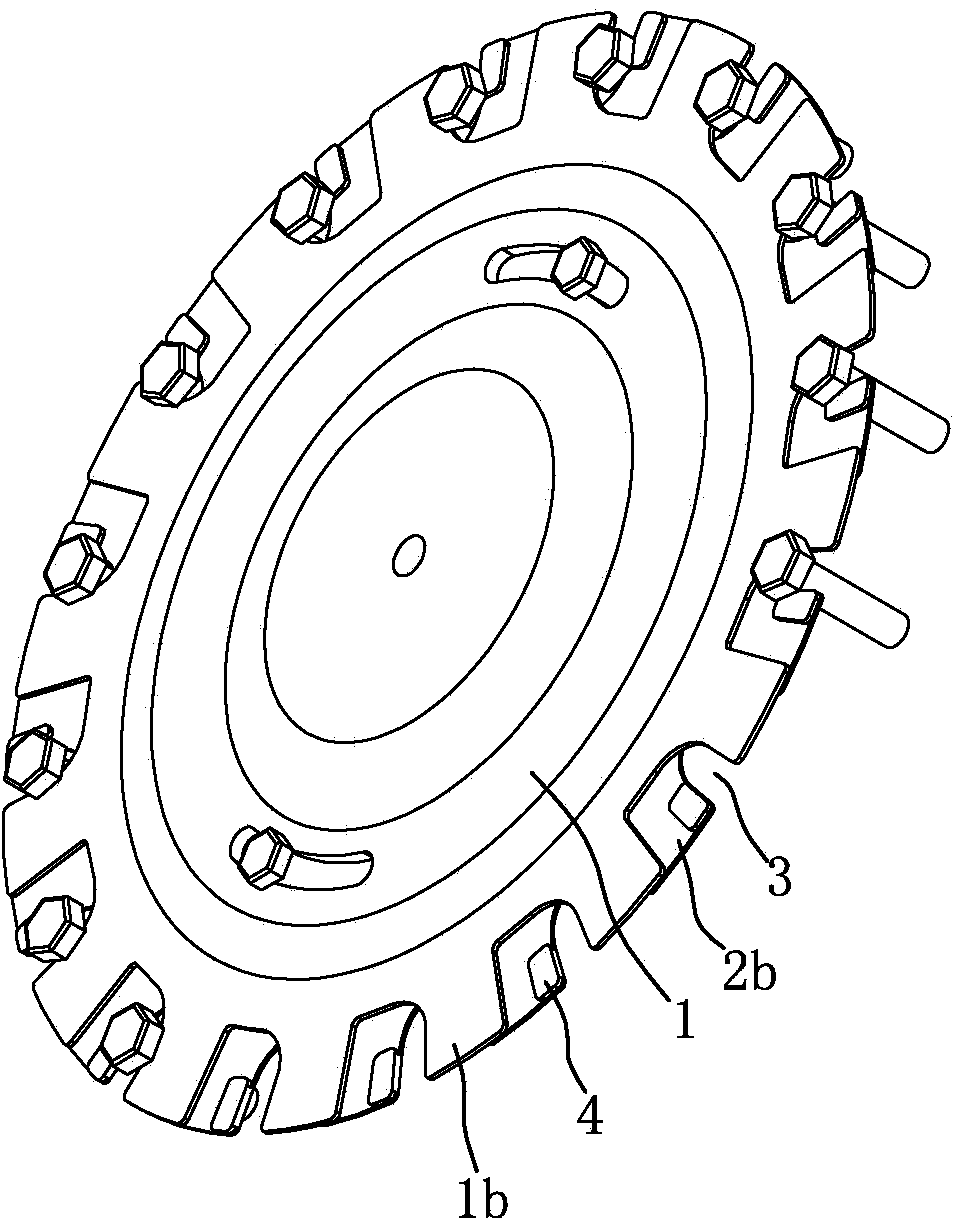

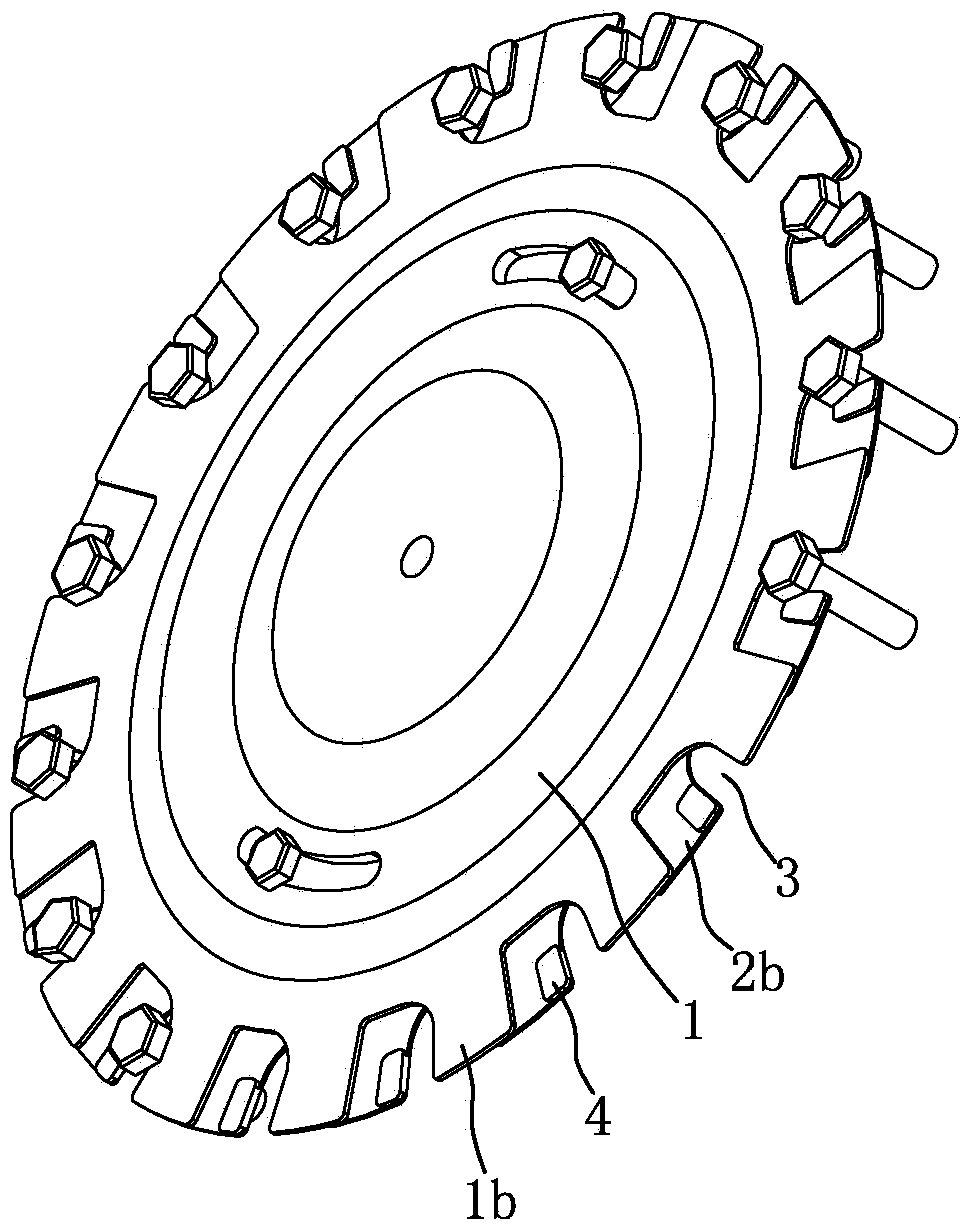

Threaded hole three-CCD camera detection mechanism

InactiveCN105004275AComprehensive samplingReduce missed detection rateOptically investigating flaws/contaminationUsing optical meansEngineeringCcd camera

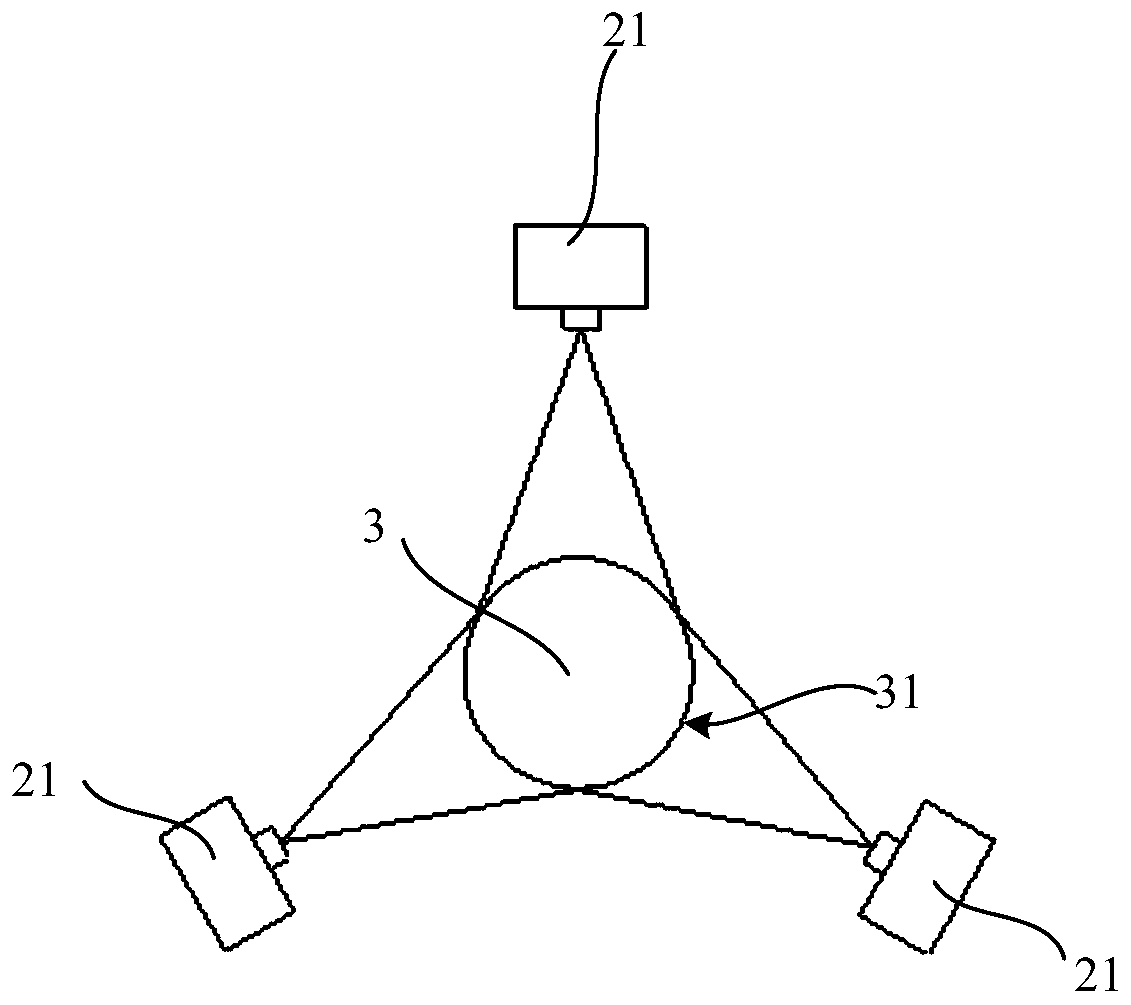

The invention relates to a threaded hole three-CCD camera detection mechanism. One end of the detection mechanism is provided with a target zone, and the detection mechanism comprises at least two image devices arranged at a certain angle. The detection mechanism is characterized in that at least one image device is arranged towards the target zone in a positive direction, at least one image device is arranged towards the target zone in an inclined manner, extension lines of lenses of the image devices intersect at the same intersection, and the intersection is positioned in the target zone. According to the detection mechanism, a CCD camera arranged in the positive direction and a CCD camera arranged in an inclined manner detect each quality index of an internal thread with clear division of labor, and the CCD cameras with two different angles are arranged on the same fixing plate so that all quality index items of the same internal thread can be integrally and simultaneously detected.

Owner:SUZHOU JQS INFO TECH CO LTD

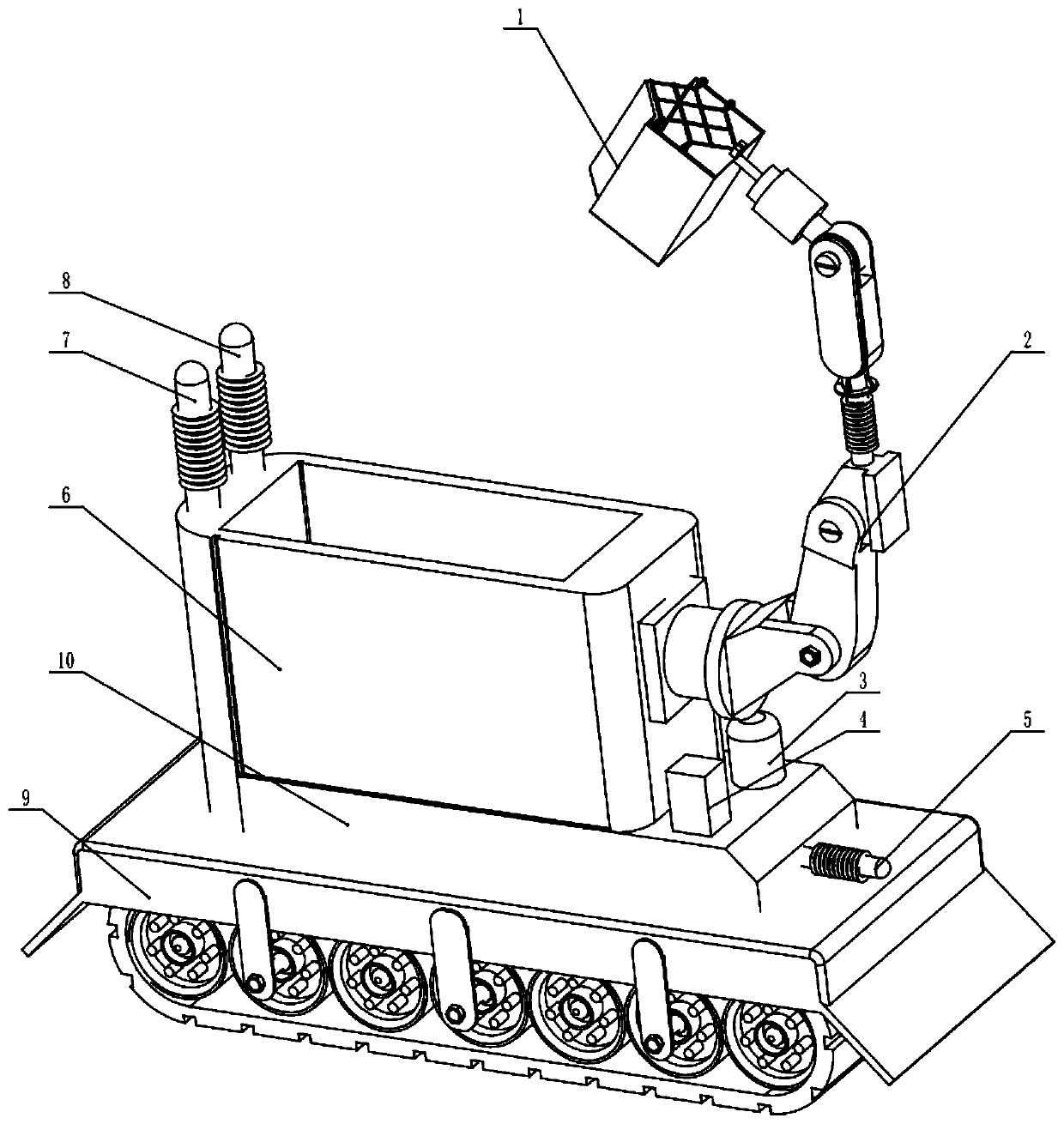

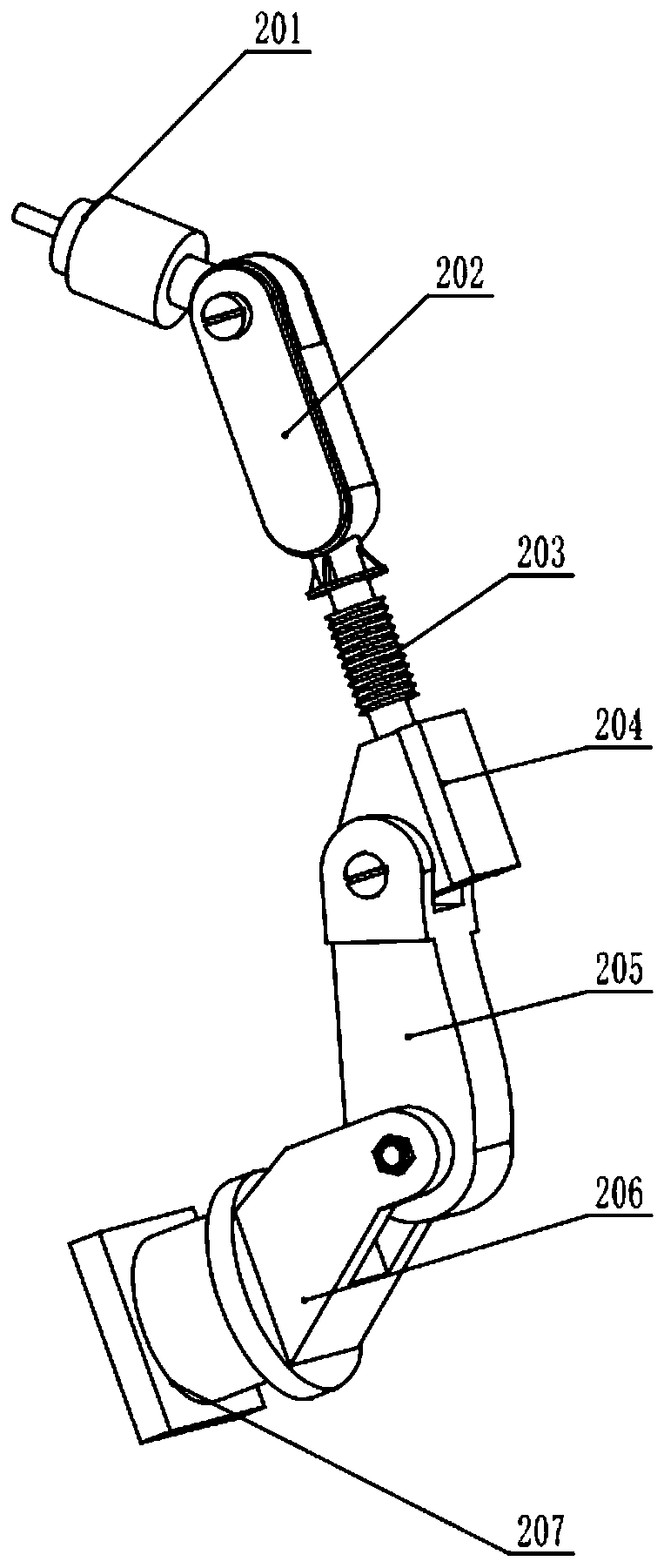

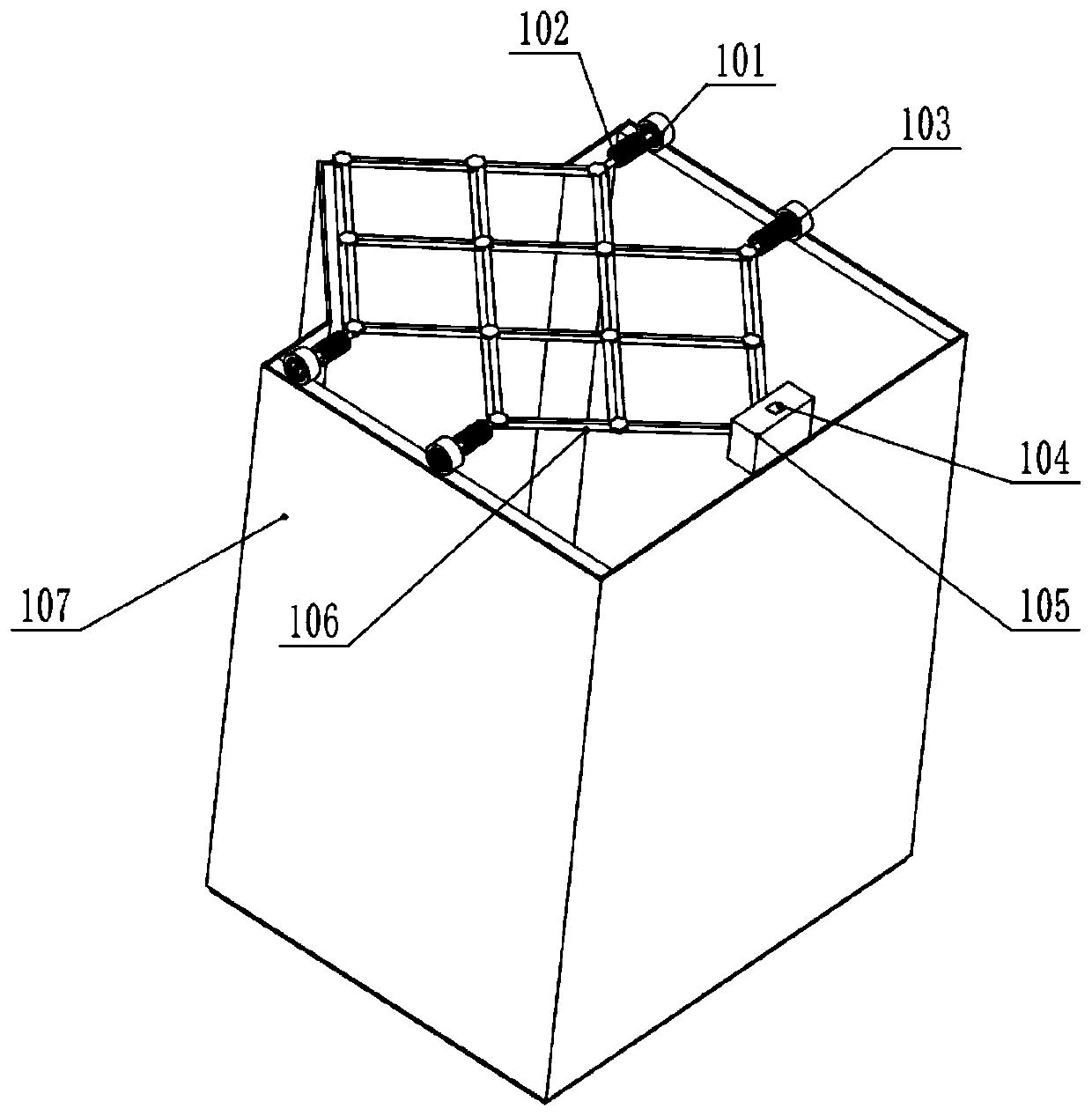

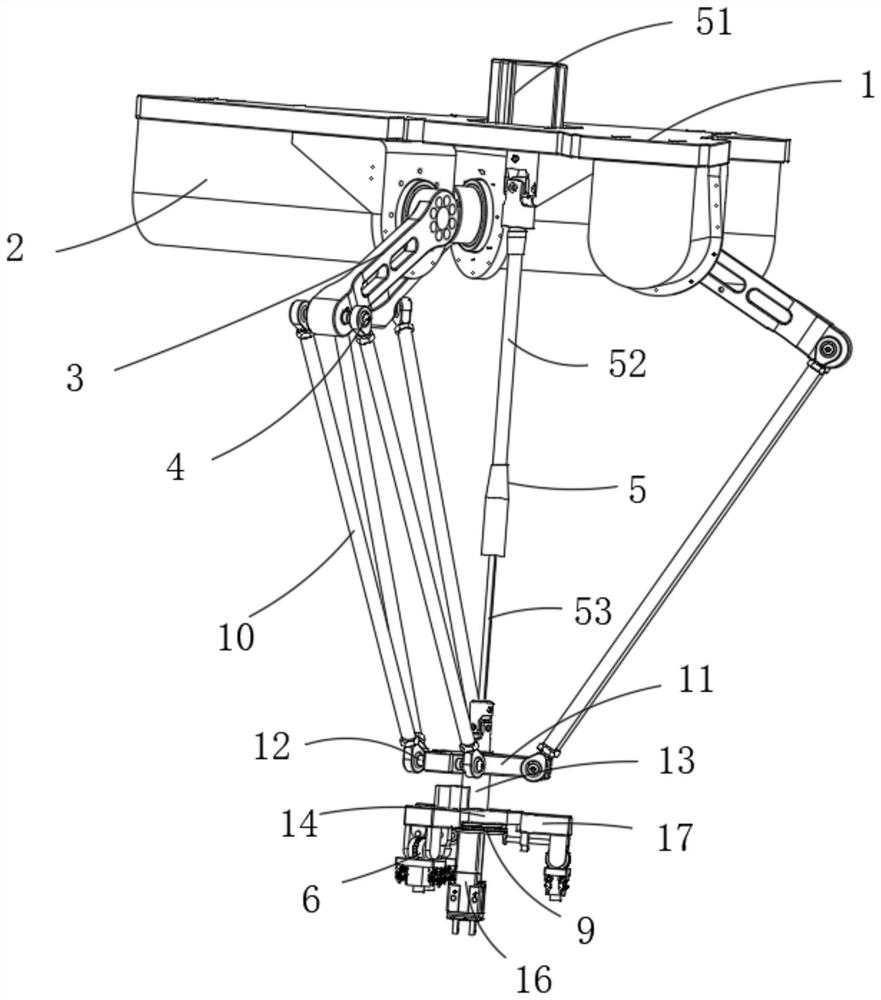

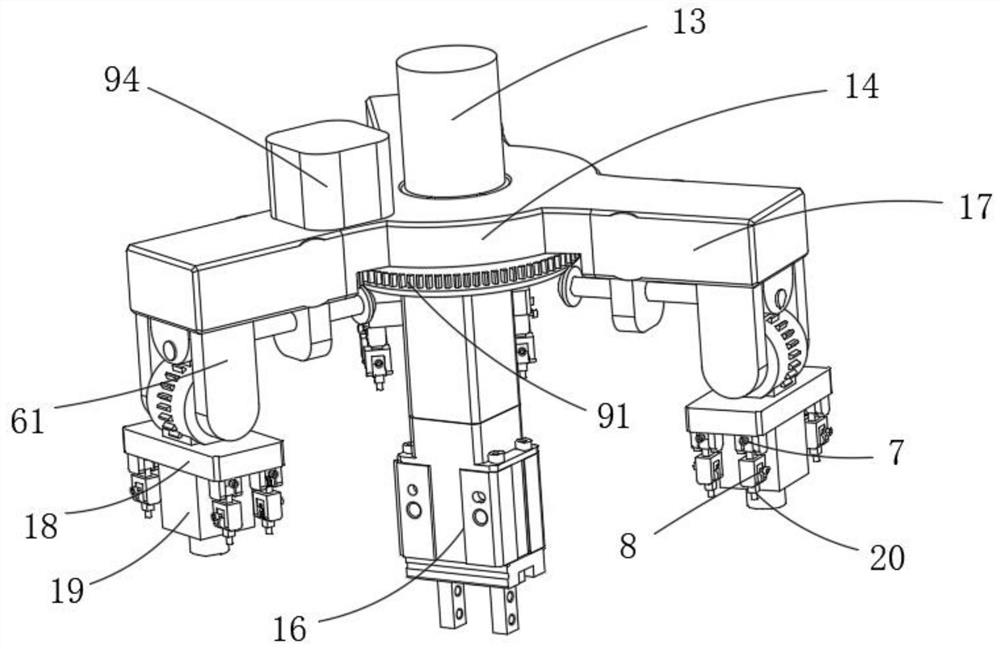

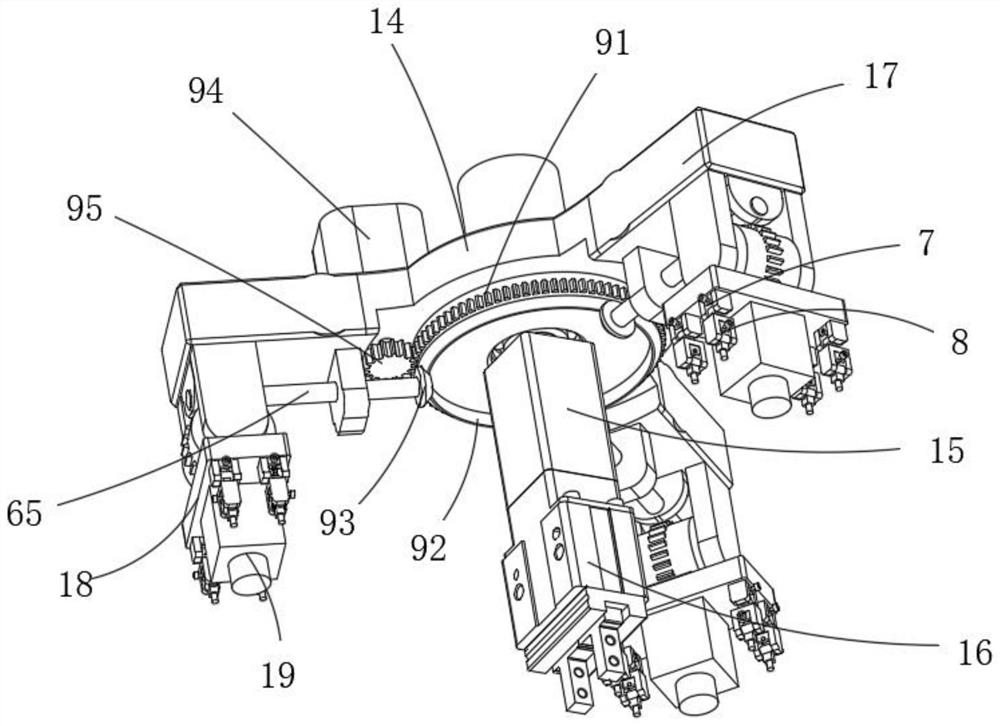

Binocular-recognition-based intelligent hawthorn picking robot

ActiveCN109729829AWon't spillSmooth goingTelevision system detailsRenewable energy machinesRobotic armComputer science

The invention provides a binocular-recognition-based intelligent hawthorn picking robot. The robot comprises a hawthorn picking device, an advancing device and an image acquiring and processing device; the hawthorn picking device comprises a mechanical arm, a small-capacity collecting device and a large-capacity collecting device; the large-capacity collecting device is a cuboid box body and is fixedly arranged on the advancing device; the advancing device is a crawler-type advancing device; and the image acquiring and processing device comprises three telescopic racks and three CCD cameras and an industrial control computer and is located on the advancing device. Hawthorn fruits are sufficiently protected due to the design that whether a scissor net is shrunk or not is judged after an image of a position relationship between hawthorns and the scissor net is sent back to the industrial control computer, hawthorn stalks are sheared, and then, picking is finished.

Owner:HEBEI UNIV OF TECH

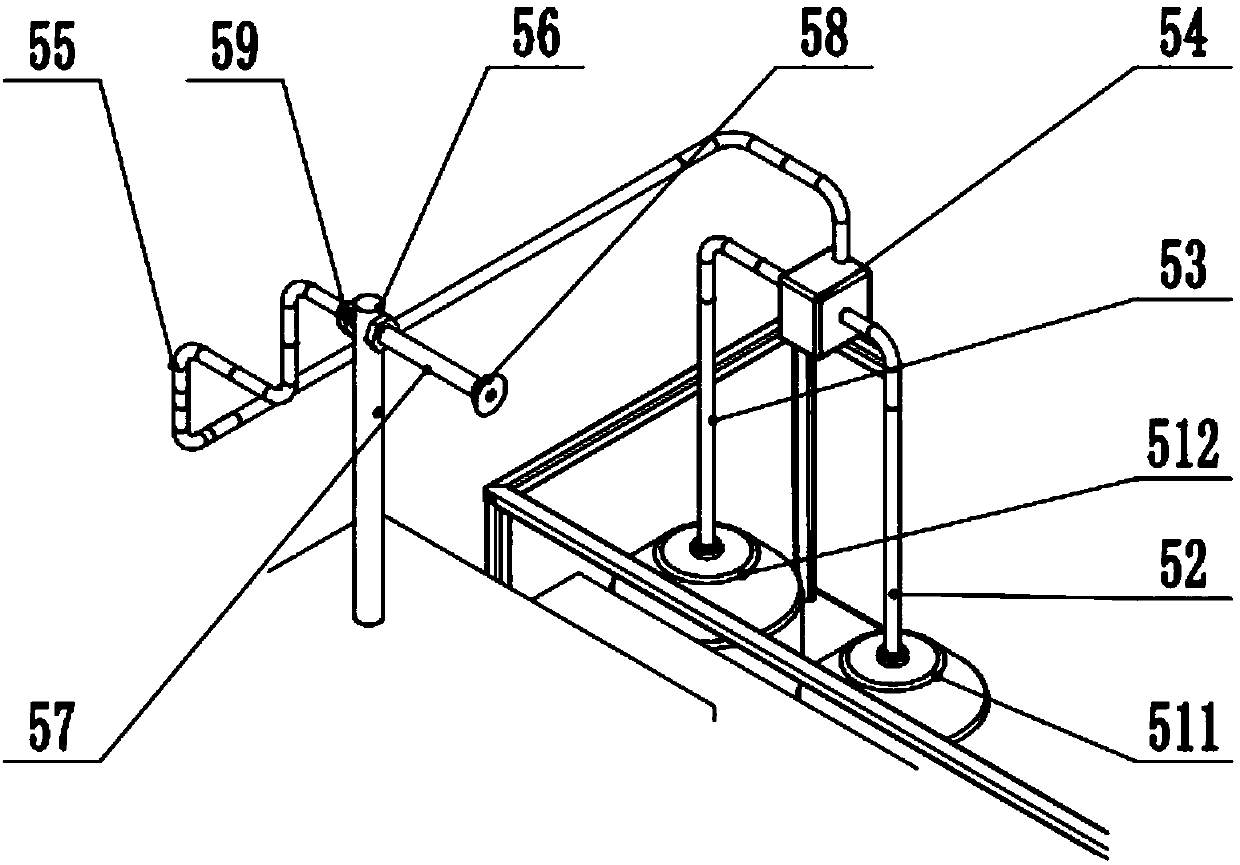

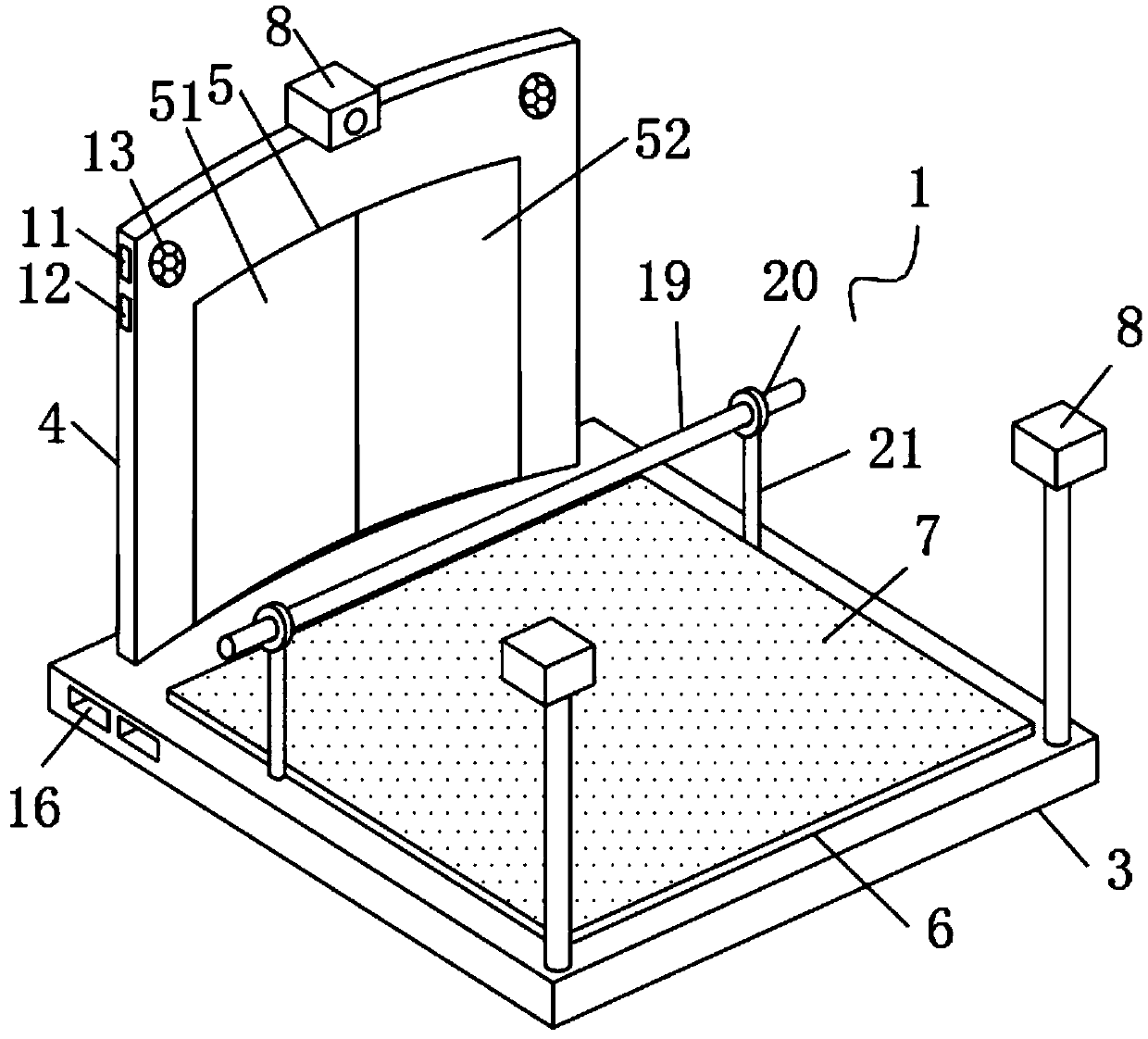

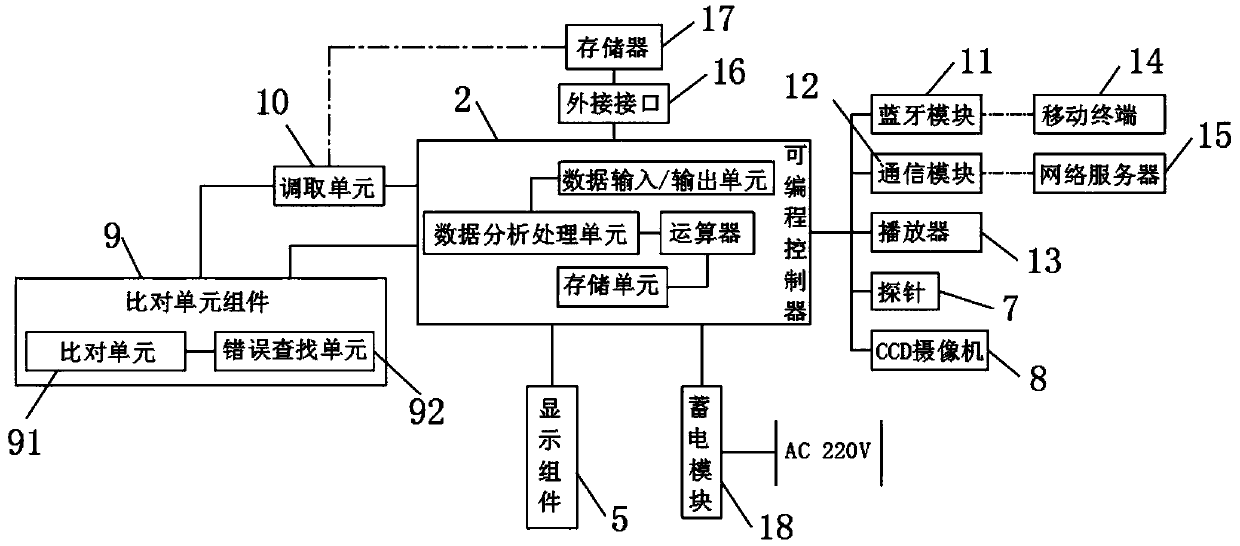

Dance independent training comparison system

InactiveCN109513194AEasy to compareGood for detecting pressure valuesStiltsCcd cameraThree-CCD camera

The invention discloses a dance independent training comparison system, and relates to the technical field of dance comparison. The system comprises a dance training machine body and a programmable controller, the dance training machine body is arranged in a cavity of the programmable controller, the dance training machine body is composed of a base and a support member, the support member is fixedly disposed on one side of the top end of the base, one side of the support member is inlaid with a display assembly arranged in an arc shape, the top of the base fits a soft cushion, a probe is disposed in the soft cushion, two CCD cameras and one CCD camera are respectively disposed on the base and the support member, and the three CCD cameras are arranged in a triangle shape. The system facilitates the comparing dances for which dancers are trained with existing standard dance movements by the arrangement of a comparing unit assembly, delineates and records the differences of the compareddances, displays through the display assembly, and provides convenience for the dancers to find the irregularities of the dances in time during the dance training.

Owner:HUNAN CITY UNIV

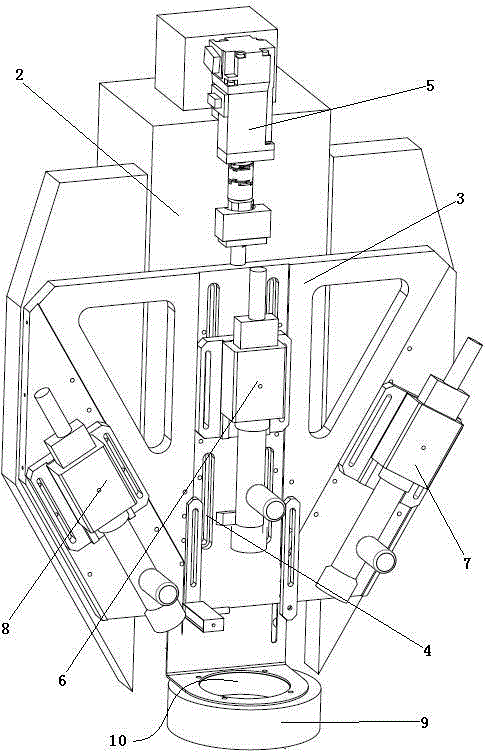

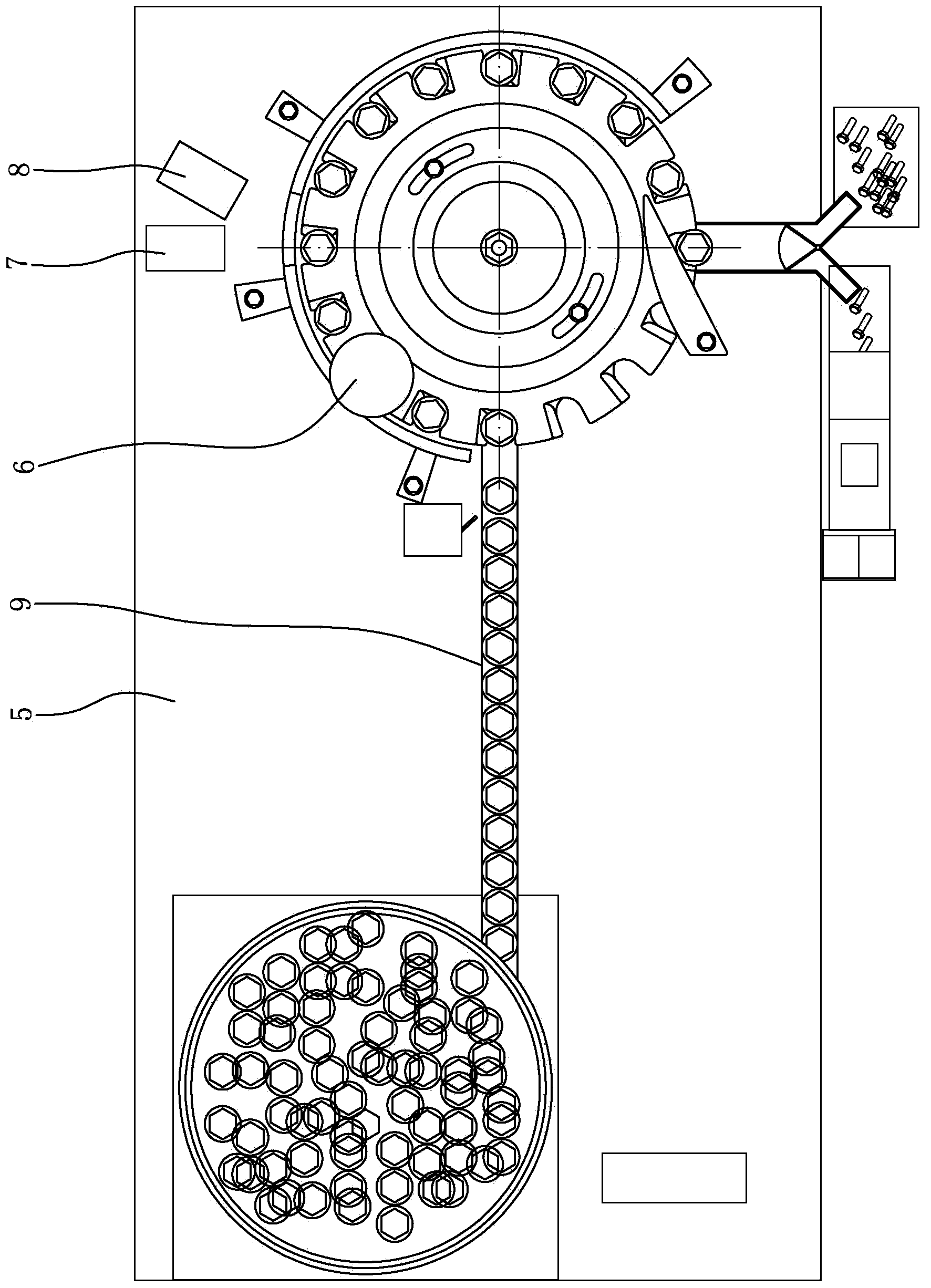

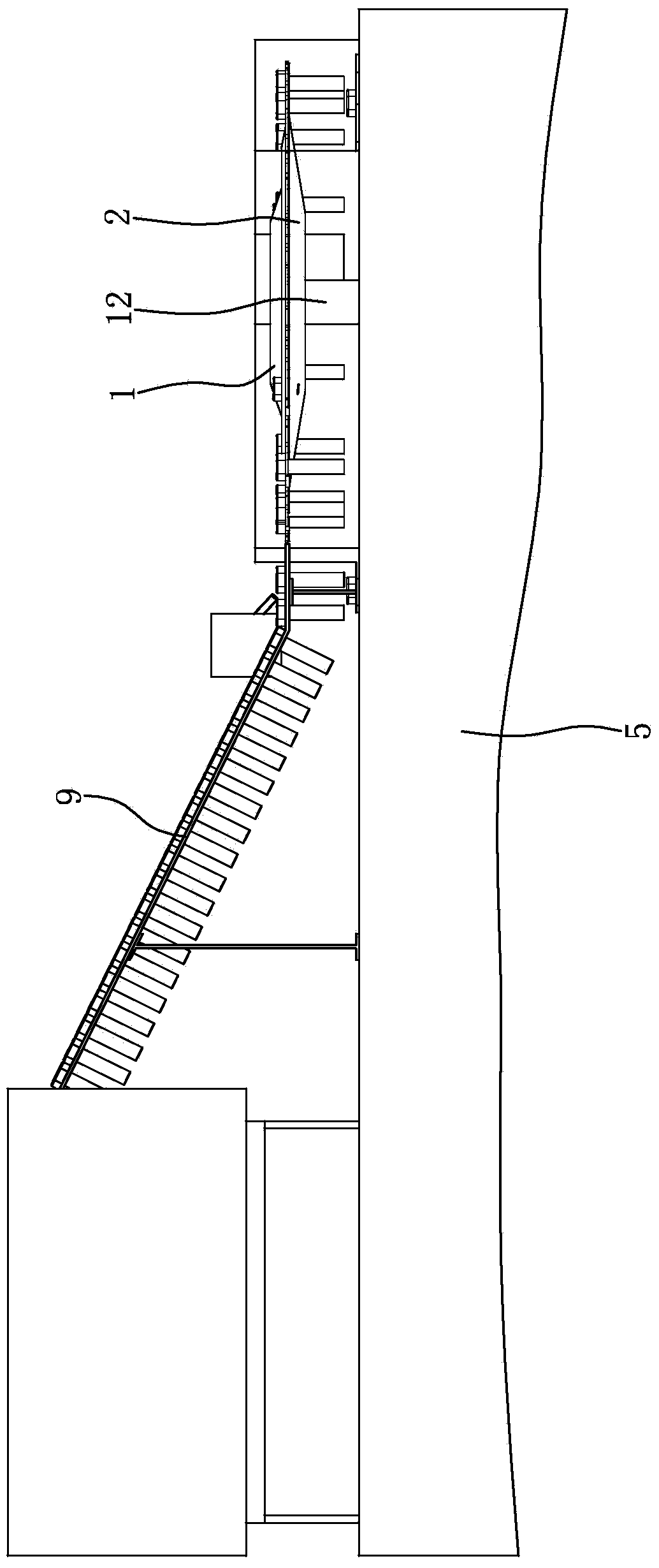

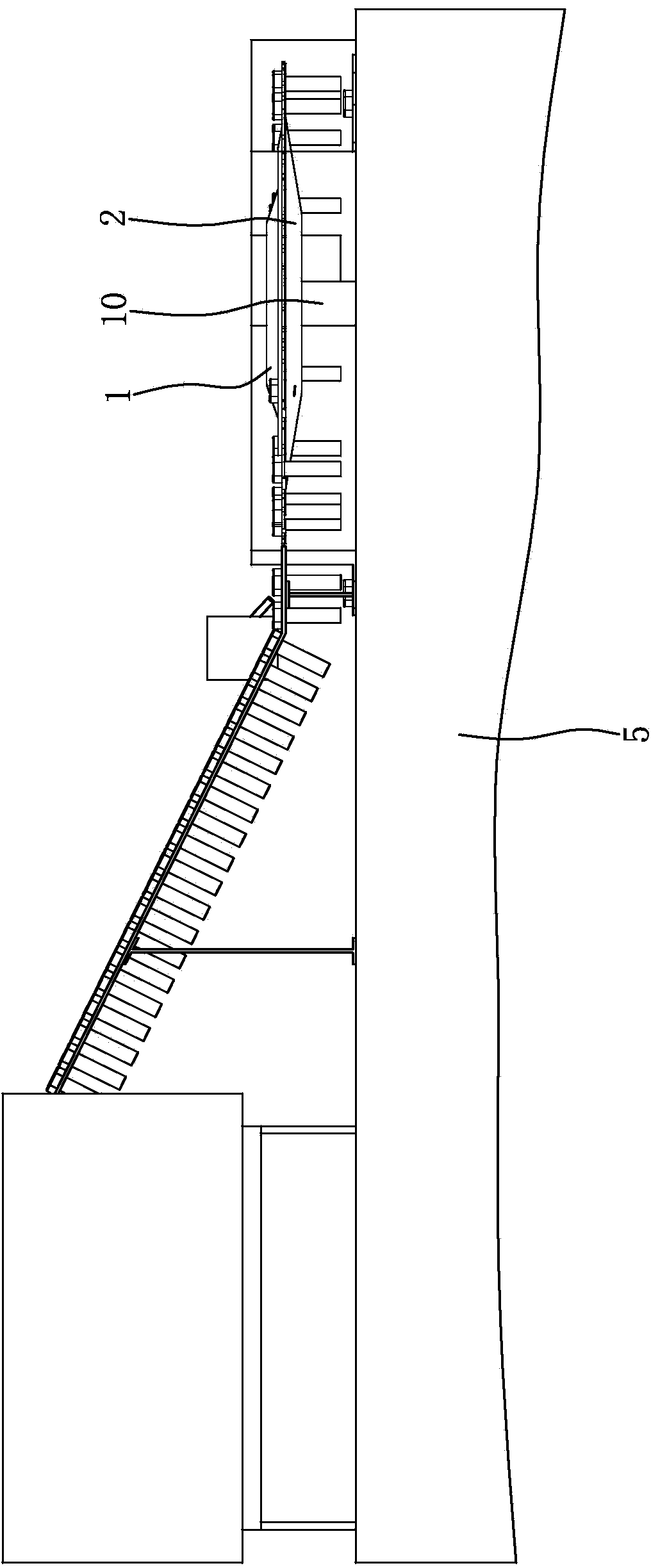

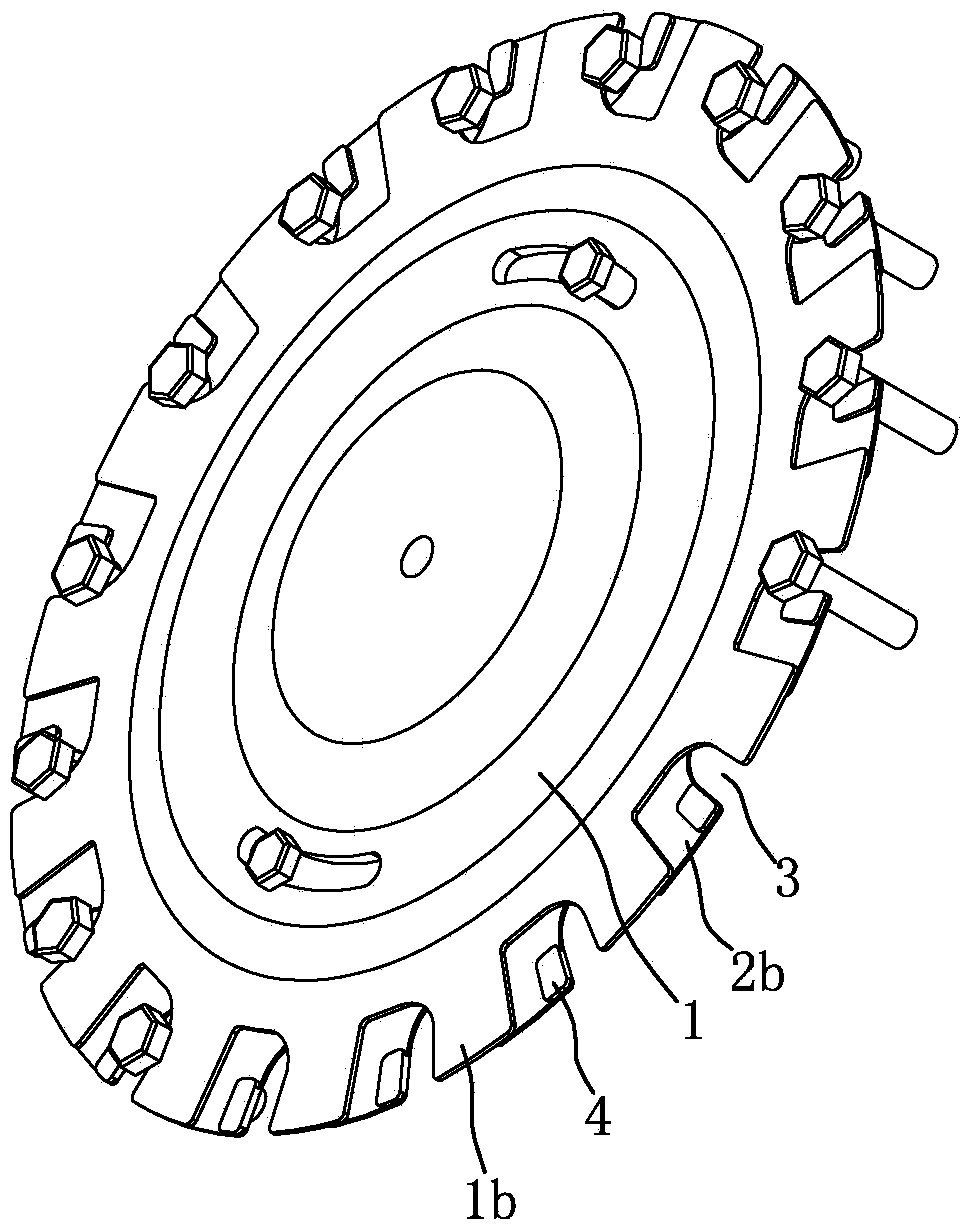

Machine vision detection mechanism for standard fasteners

InactiveCN104237248AImprove versatilityHigh degree of automationOptically investigating flaws/contaminationUsing optical meansMachine visionEngineering

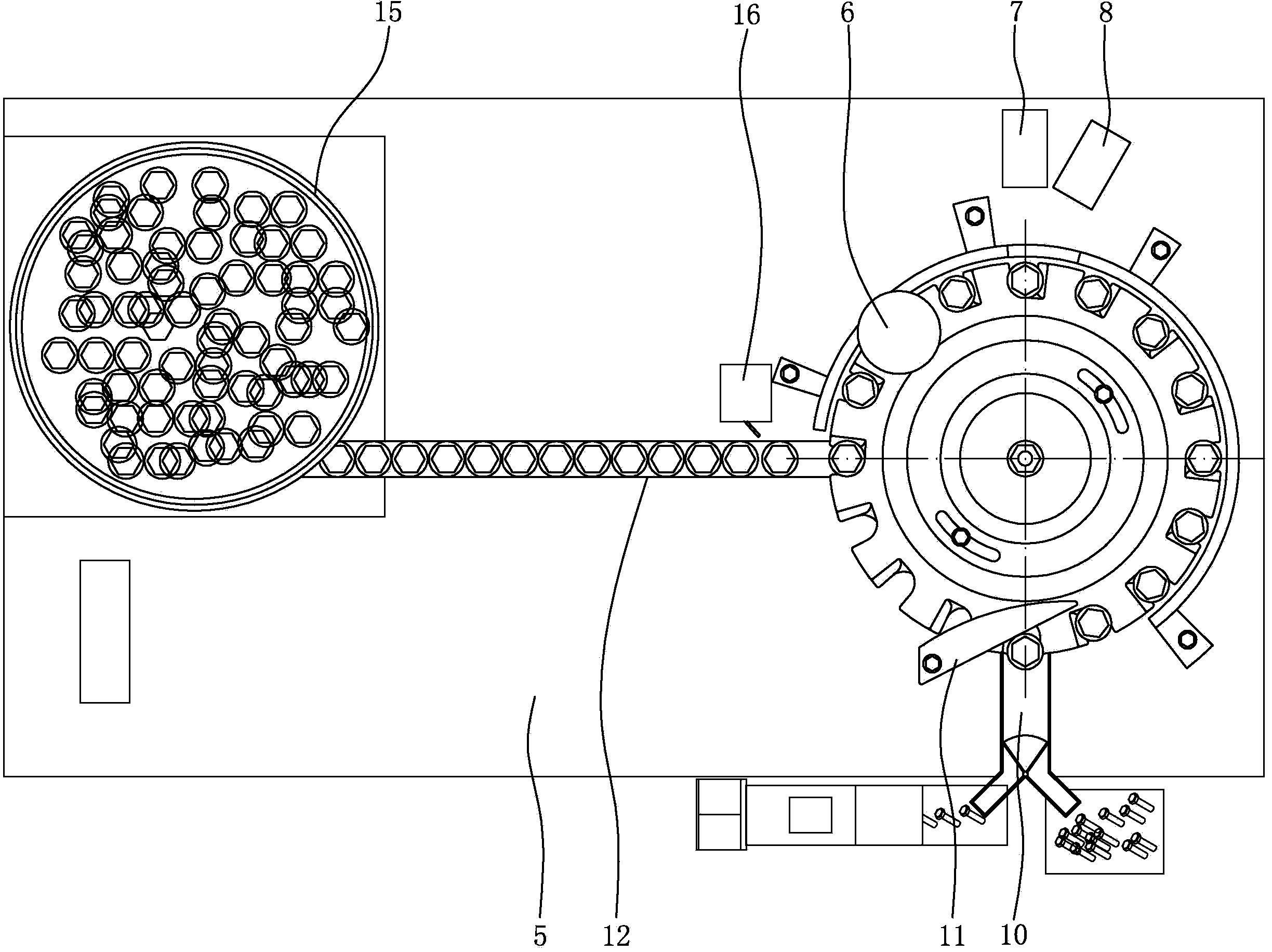

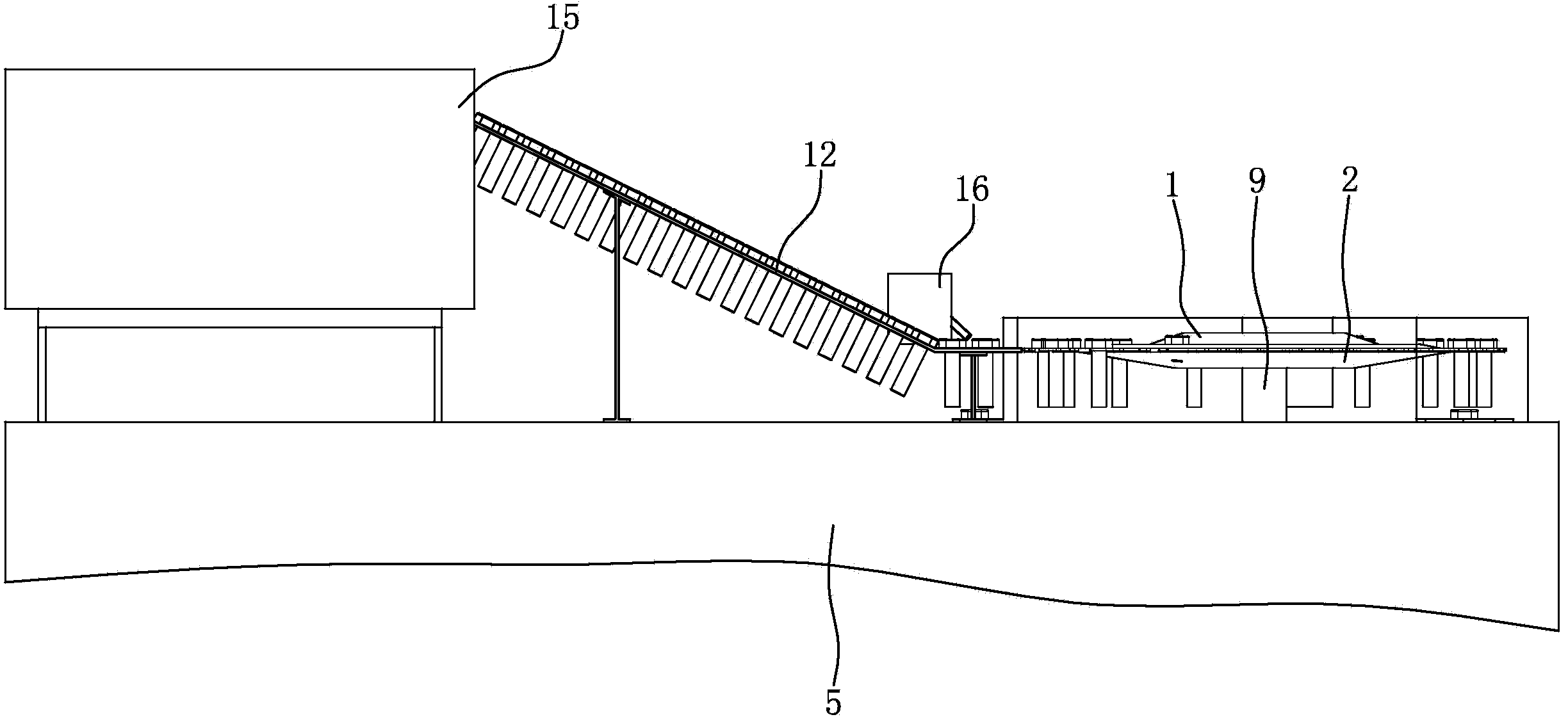

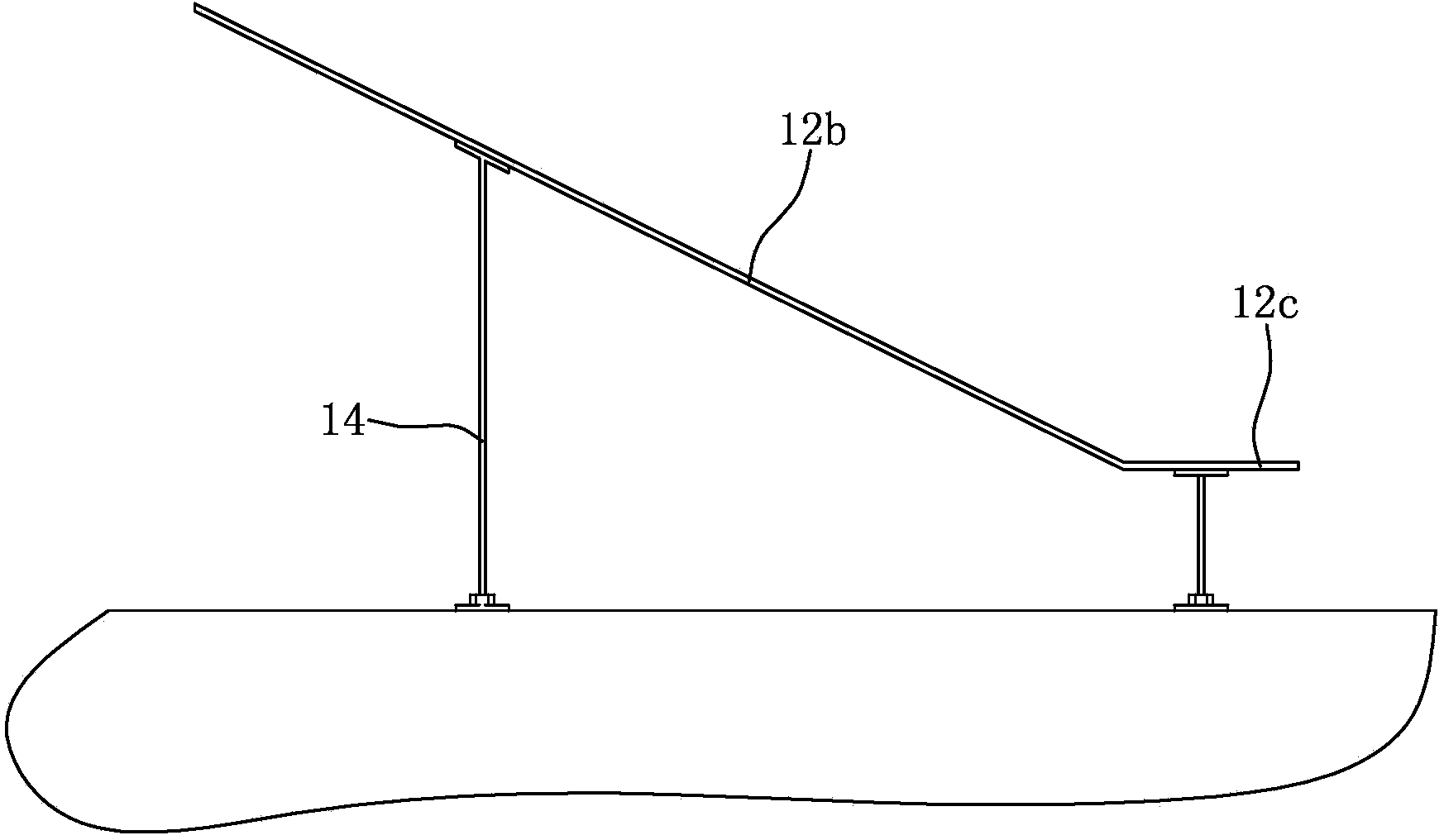

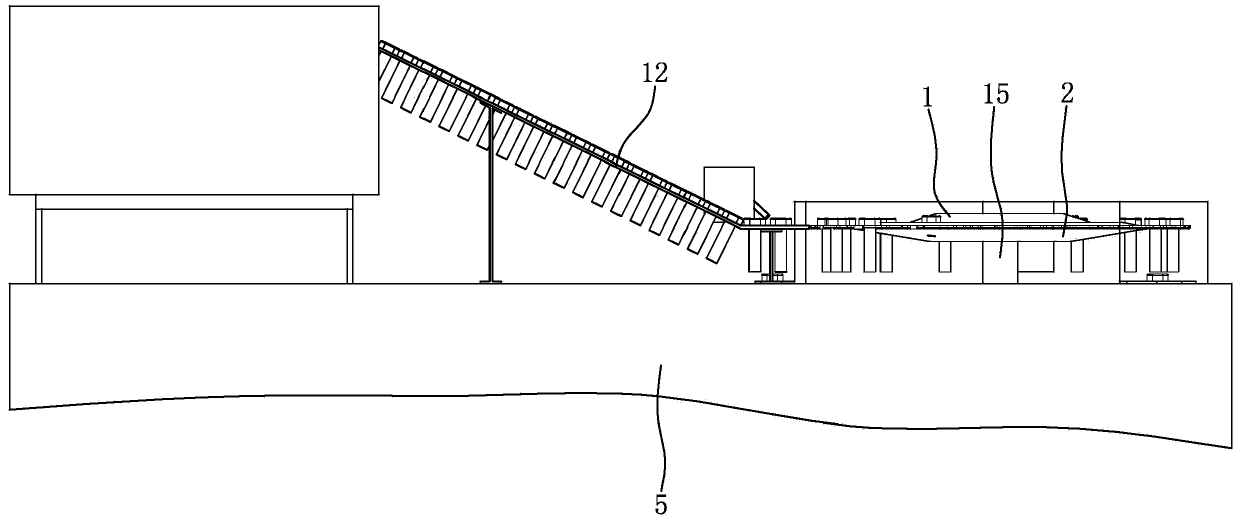

The invention discloses a machine vision detection mechanism for standard fasteners. A vibrating disk (15) is arranged at one end of the top part of a machine stand (5), an indexing turntable is arranged at the other end of the top part of the machine stand (5), a guide rail (12) for conveying parts is arranged between the vibrating disk (15) and the indexing turntable, the guide rail (12) is composed of a fixed conveying rail (12a) and an adjustable conveying rail (12b), which are arranged side by side, the outlet ends of the fixed conveying rail (12a) and the adjustable conveying rail (12b) are bent upwards to form a horizontal section (12c), and a blowing device (16) is arranged on the side edge of the outlet end of the guide rail (12). The machine vision detection mechanism adopts three CCD cameras to shoot images of the parts in different angles, can be used for automatically completing conveying, detection, sorting and packaging of the standard fasteners, can be used for detecting the various standard fasteners, can be adaptive to the to-be-detected parts with different specifications, and is good in universality, high in automation degree and high in detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

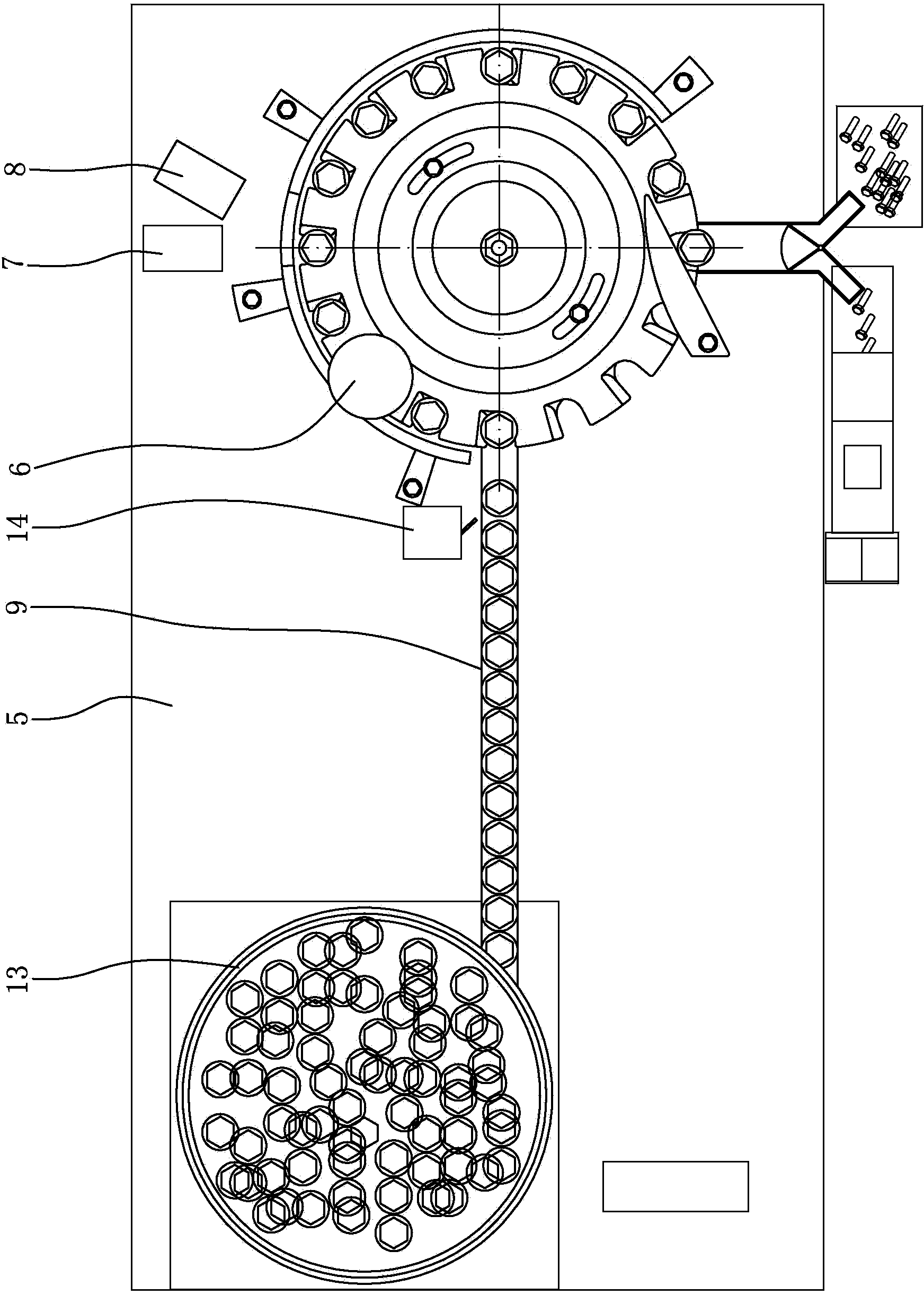

Visual inspection mechanism

InactiveCN104142334AImprove versatilityHigh degree of automationOptically investigating flaws/contaminationUsing optical meansVisual inspectionEngineering

The invention discloses a visual inspection mechanism. A vibrating plate (13) is installed at one end of the top of a machine table (5), and a scale division rotating plate is arranged at the other end of the top of the machine table (5). A guide rail (9) for conveying parts is arranged between the vibrating plate (13) and the scale division rotating plate and formed by a fixed conveying rail body (9a) and an adjustable conveying rail body (9b) which are arranged side by side, the outlet ends of the fixed conveying rail body (9a) and the adjustable conveying rail body (9b) are both upwards bent to form horizontal sections (9c), and a blowing device (14) is arranged on the lateral side of the outlet end of the guide rail (9). By means of the visual inspection mechanism, pictures of the parts are shot through three CCD cameras from different angles, standard fasteners can be automatically conveyed, inspected, sorted and packaged, the visual inspection mechanism can be used for inspecting the fasteners in various standards, can be suitable for the to-be-inspected parts in different specifications and is good in university and high in automation degree, the device investment is effectively reduced, and the inspection efficiency is greatly improved.

Owner:CHONGQING YINGQUAN STANDARD PARTS

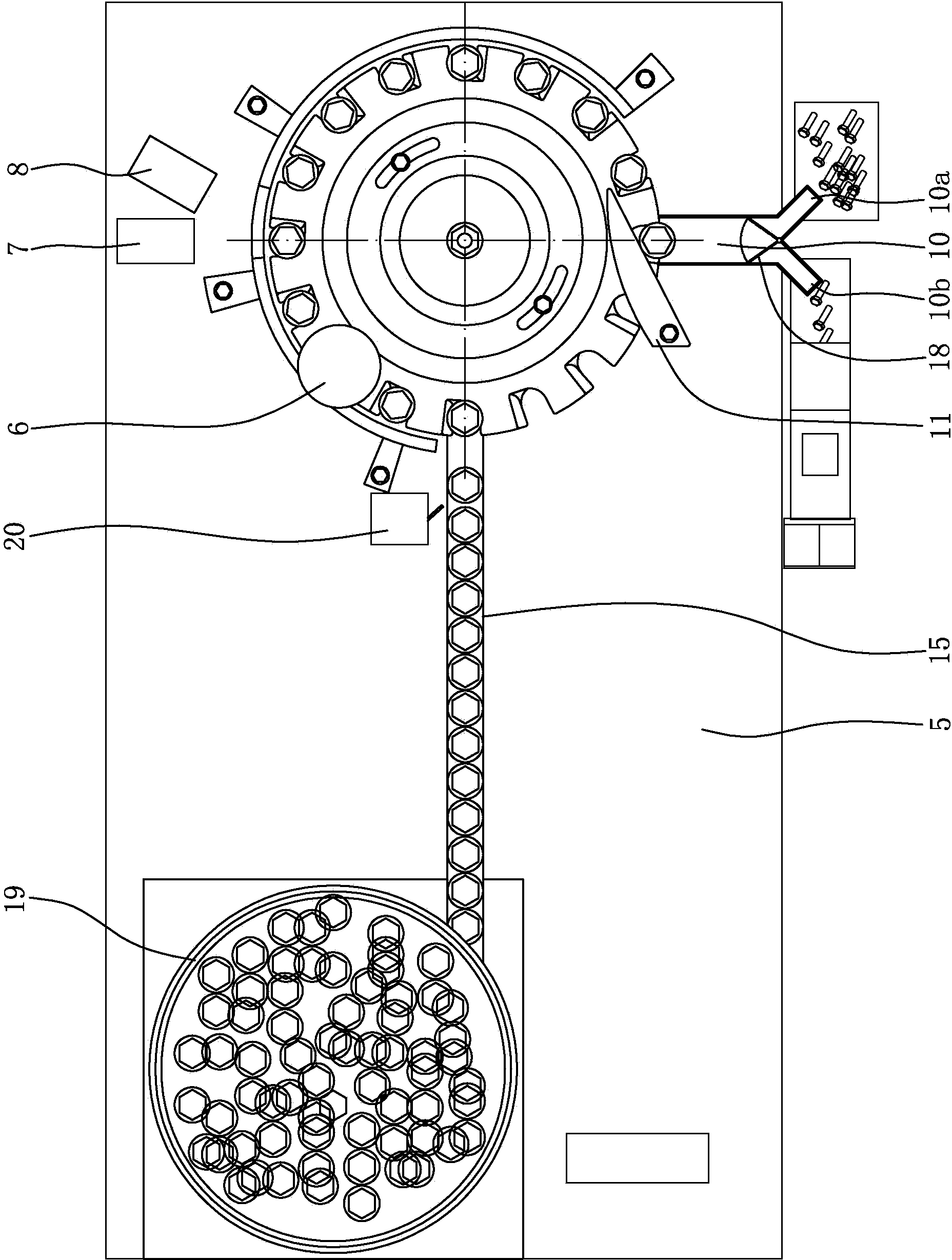

Standard fastener detection system based on machine vision

InactiveCN104142337AThe working process is simple and fastHigh degree of automationOptically investigating flaws/contaminationUsing optical meansMachine visionEngineering

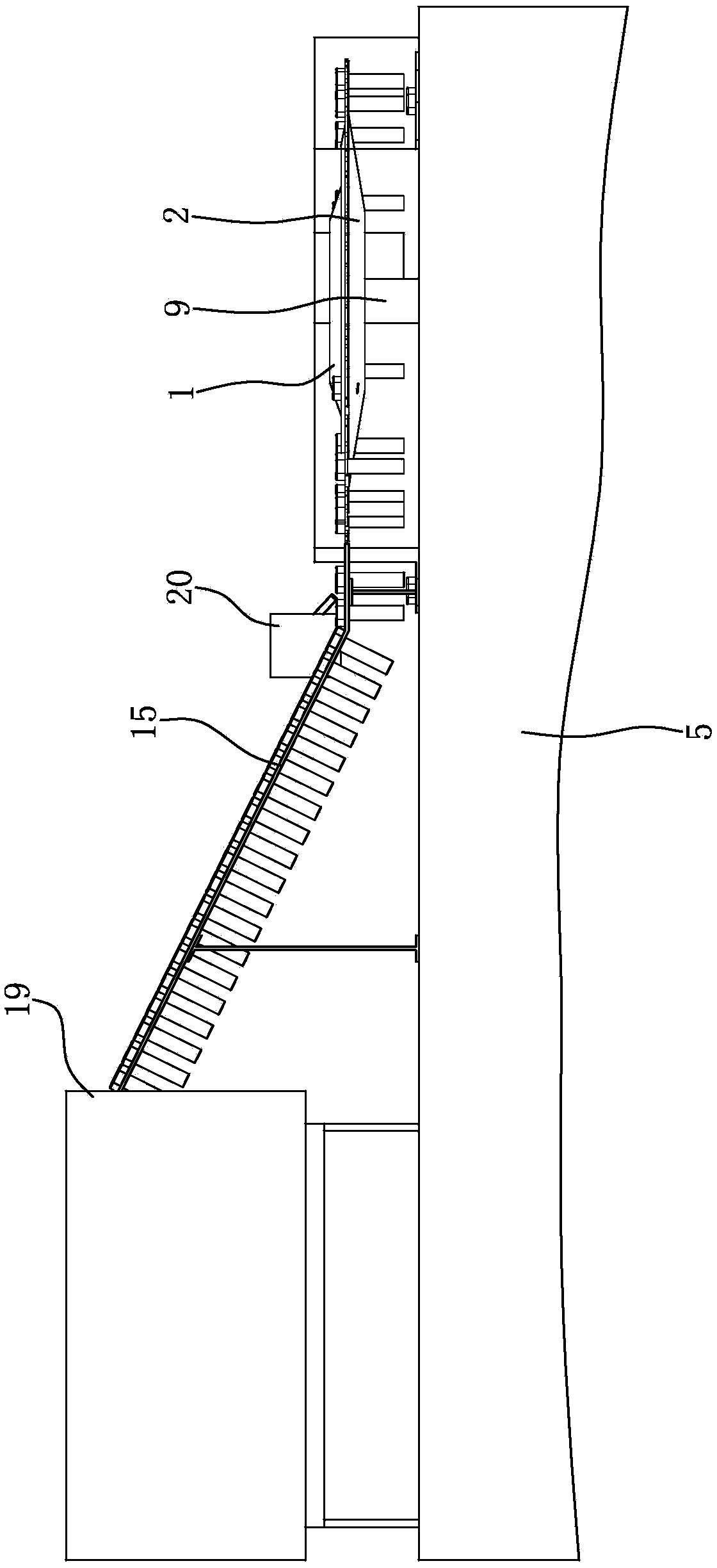

The invention discloses a standard fastener detection system based on machine vision. A vibrating disk (19) is installed at one end of the top of a machine table (5), a rotary indexing disk is arranged at the other end of the top of the machine table (5), guide rails (15) for conveying parts are arranged between the vibrating disk (19) and the rotary indexing disk, the guide rails (15) are composed of the fixed conveying rail (15a) and the adjustable conveying rail (15b) which are arranged side by side, both the outlet end of the fixed conveying rail (15a) and the outlet end of the adjustable conveying rail (15b) are bent upward to form horizontal segments (15c), and an air blowing device (20) is arranged on the lateral side of the outlet ends of the guide rails (15). According to the standard fastener detection system based on machine vision, the pictures of parts can be taken through three CCD cameras from different angles, standard fasteners can be conveyed, detected, sorted and packaged automatically, and the standard fastener detection system based on machine vision can be used for detecting various standard fasteners and sorting parts through a sorting device according to categories and is high in sorting speed, automation degree and detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

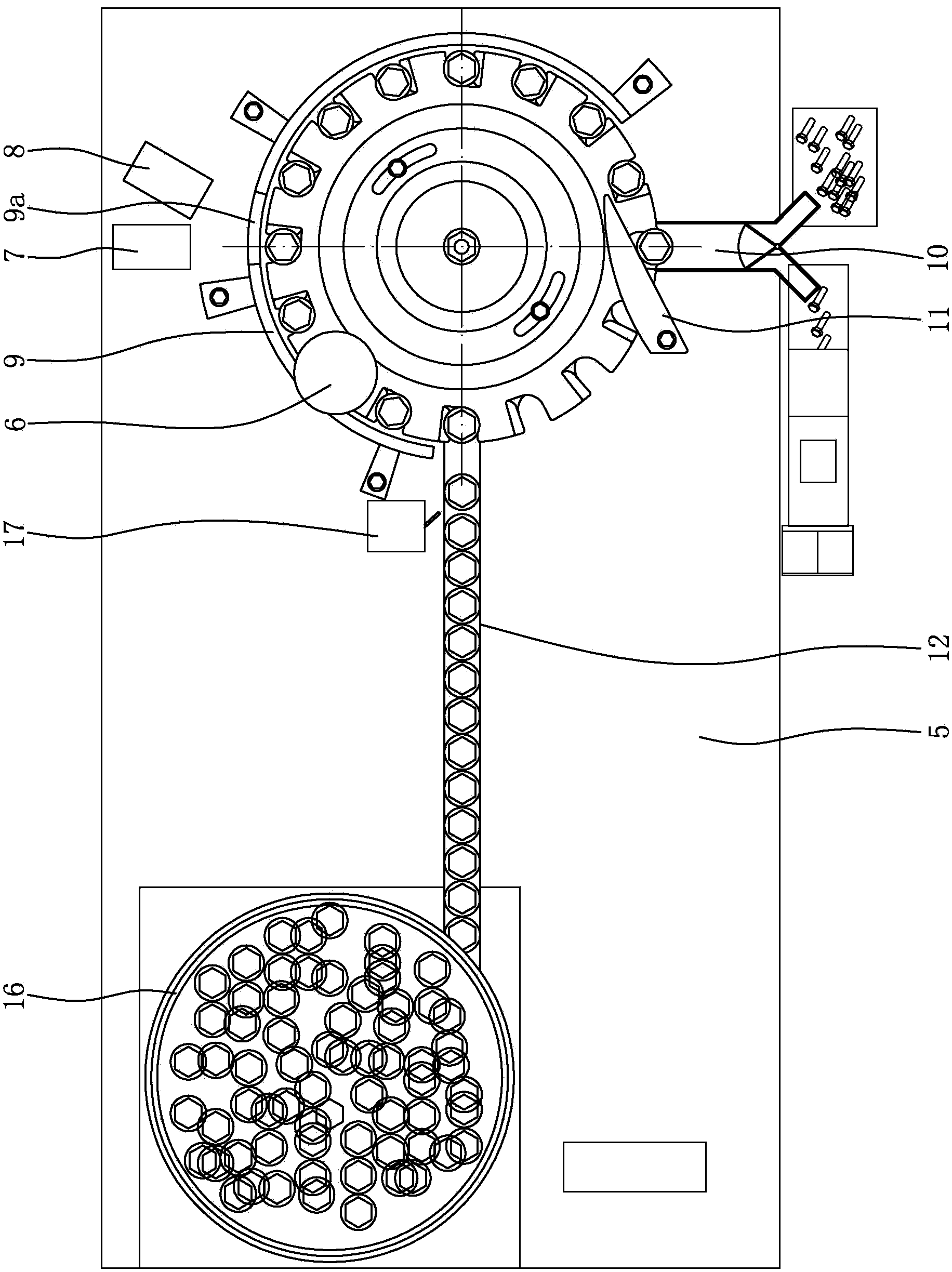

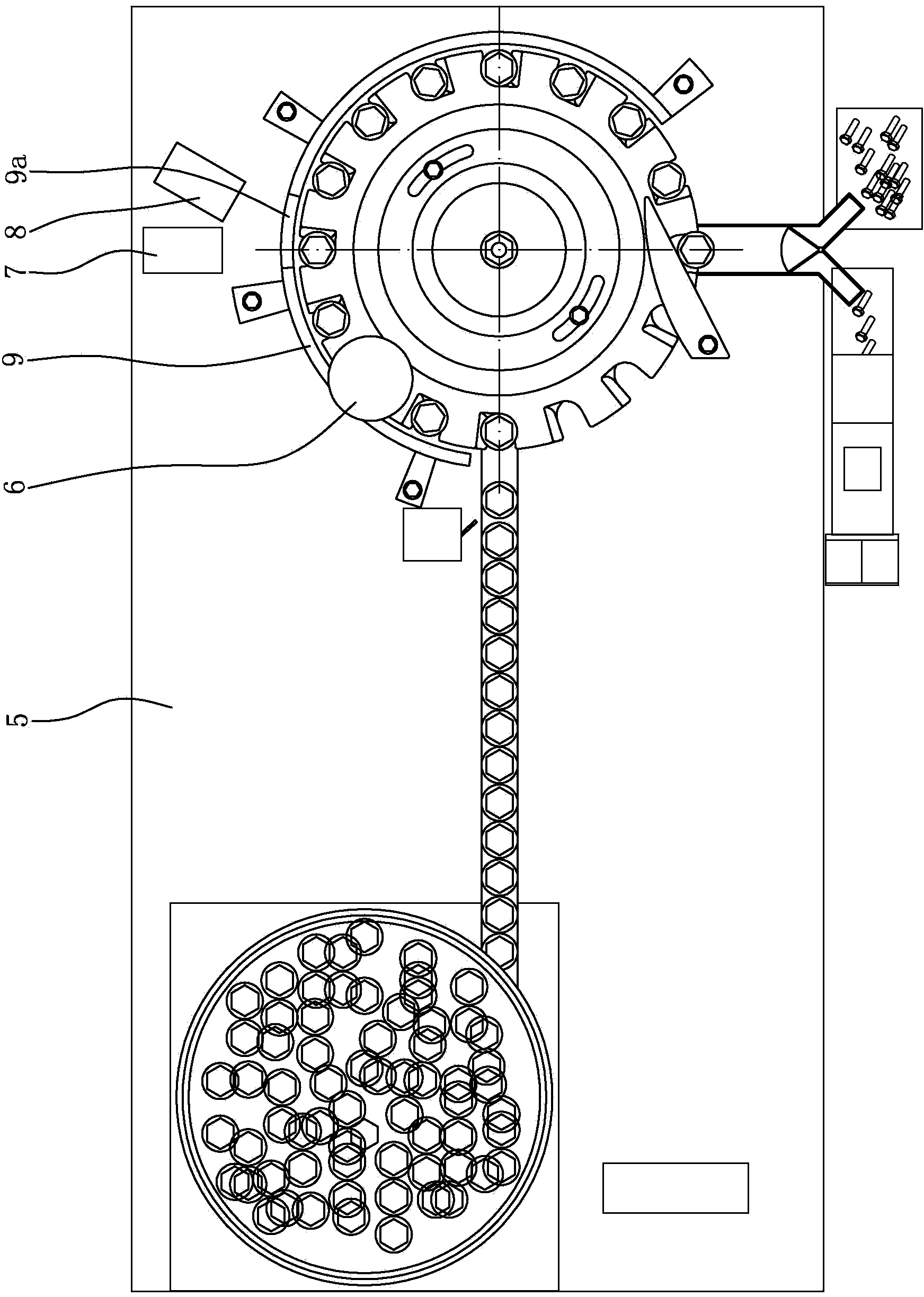

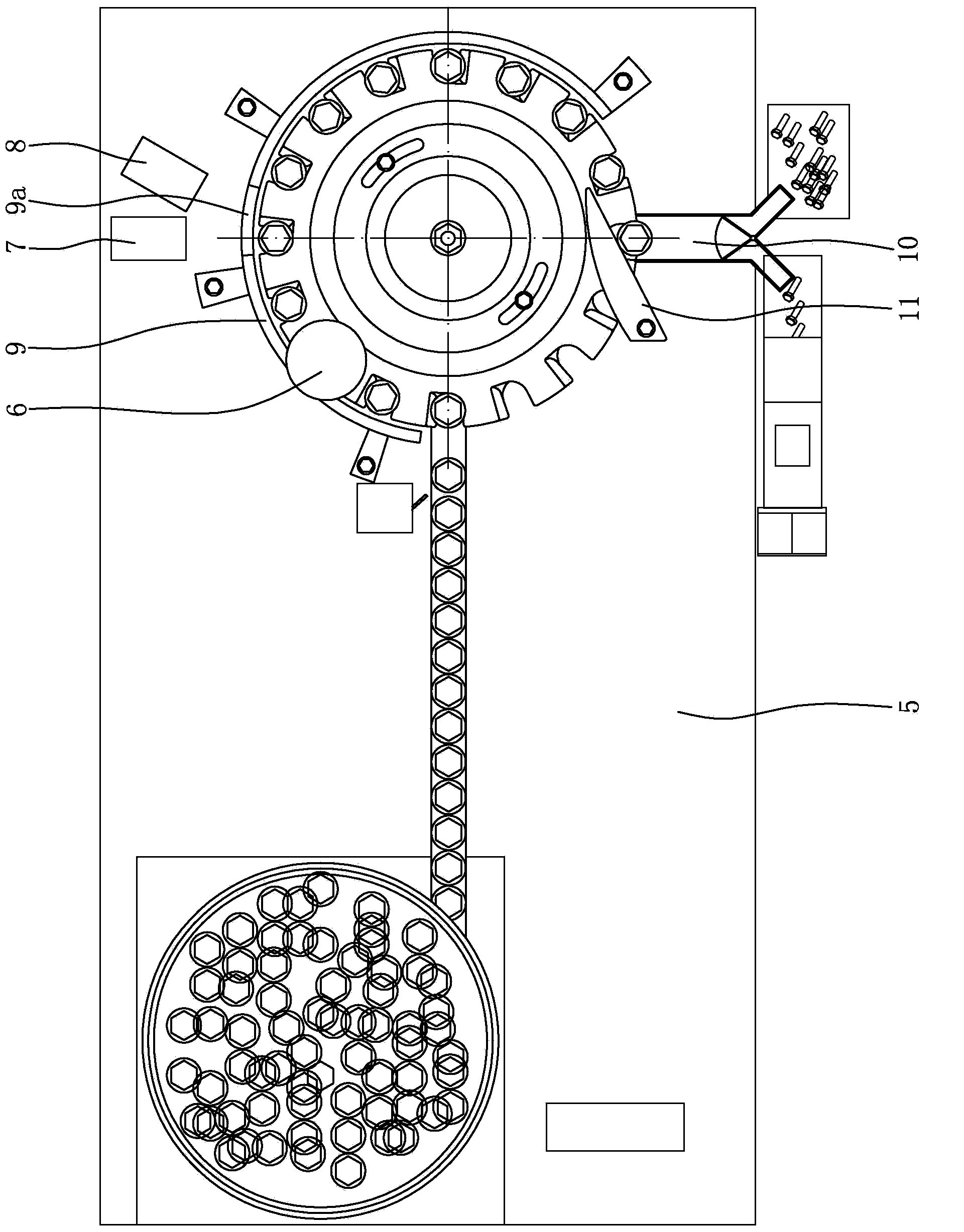

Mechanism for detecting standard fastener

InactiveCN104181166AWon't shakeImprove stabilityOptically investigating flaws/contaminationUsing optical meansCcd cameraComputer science

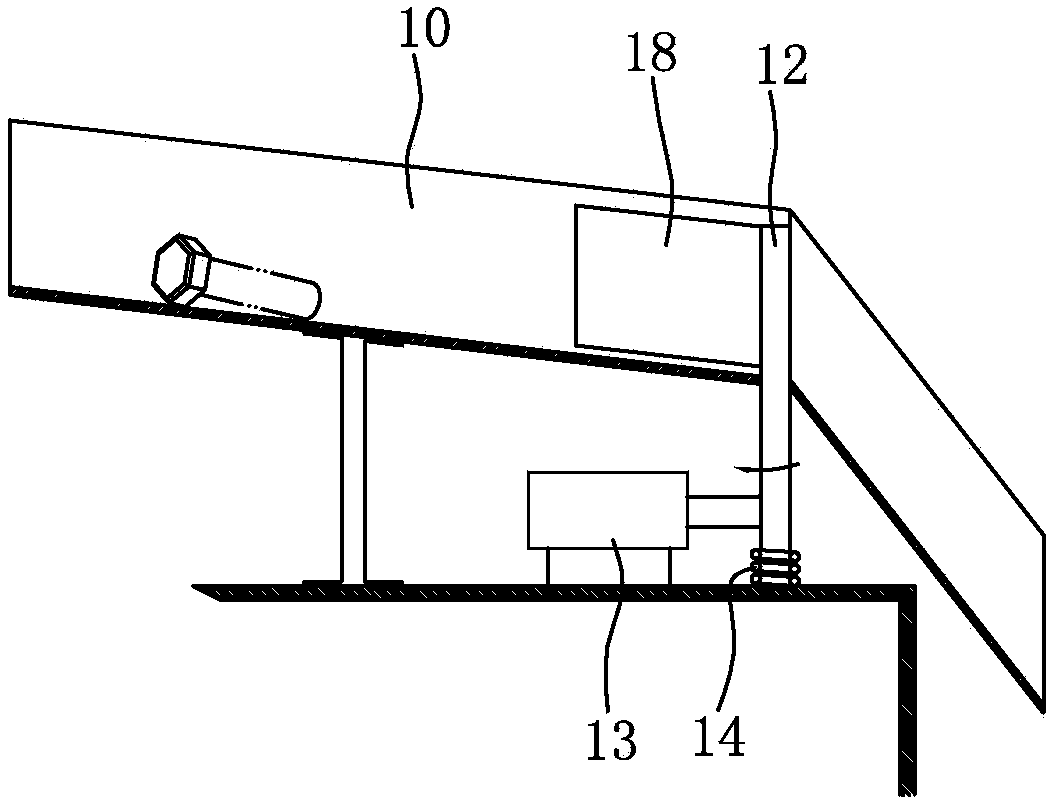

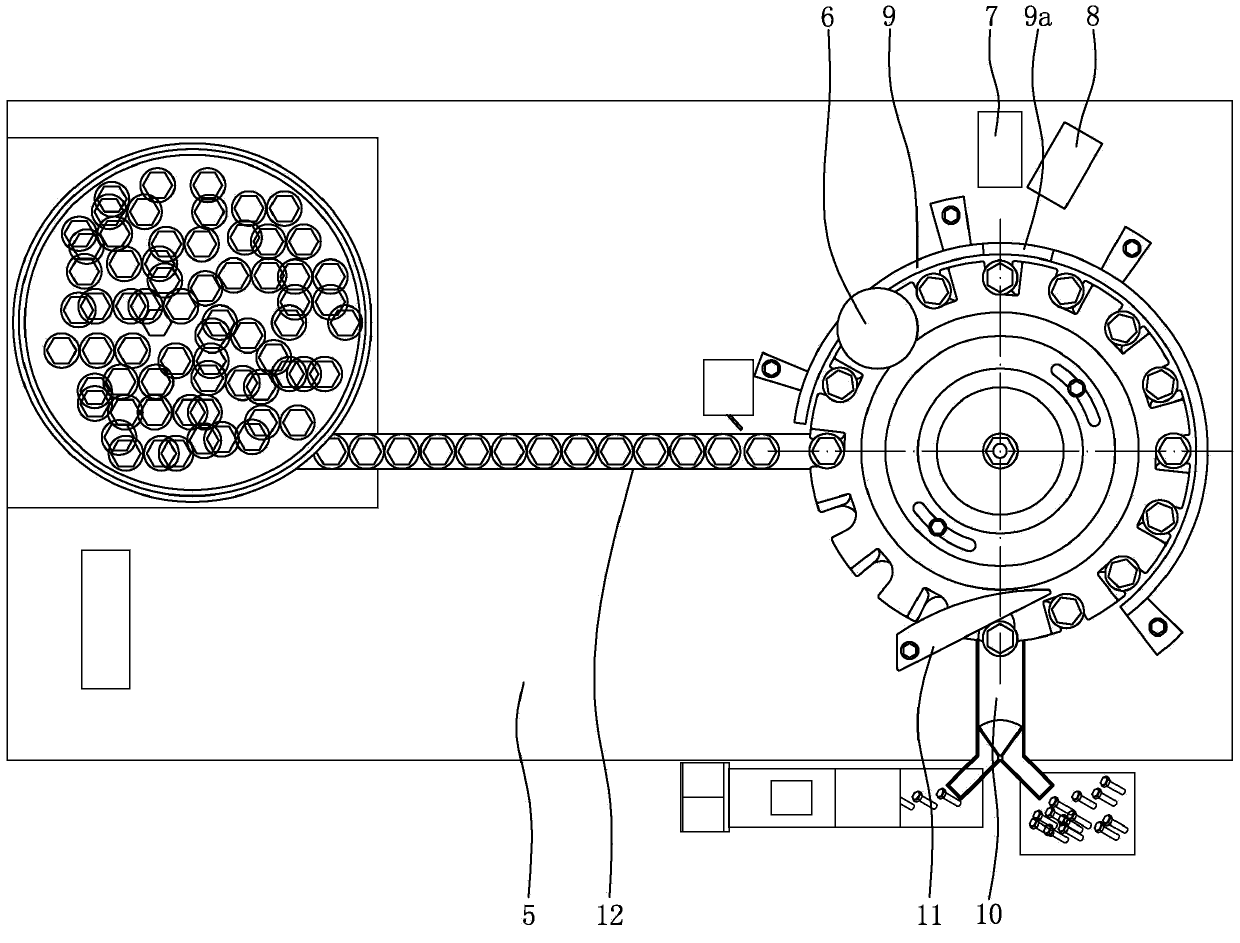

The invention discloses a mechanism for detecting a standard fastener. An indexing rotating plate is arranged above a machine stand (5), a first CCD camera (6) is arranged above the edge of the indexing rotating plate, and a second CCD camera (7) and a third CCD camera (8) are arranged by the side of the indexing rotating plate; an anti-dropping baffle plate (9) half surrounds the periphery of the indexing rotating plate; a slide-way (10) is also arranged by the side of the indexing rotating plate; a guide rail (12) is arranged on one side of the indexing rotating plate, the guide rail (12) is obliquely arranged in a way that an inlet end is higher than an outlet end, and the guide rail (12) is composed of a fixed conveying rail (12a) and an adjustable conveying rail (12b) which are arranged side by side. A component can be photographed by the three CCD cameras in different angles, the mechanism can be used for detecting different standard fasteners, and the mechanism is applicable to different to-be-detected components of different specifications while the standard fastener is prevented from dropping. The mechanism has the characteristics of simple and compact structure, small size, low cost, good universality, high automation degree, high detection efficiency and the like.

Owner:CHONGQING YINGQUAN STANDARD PARTS

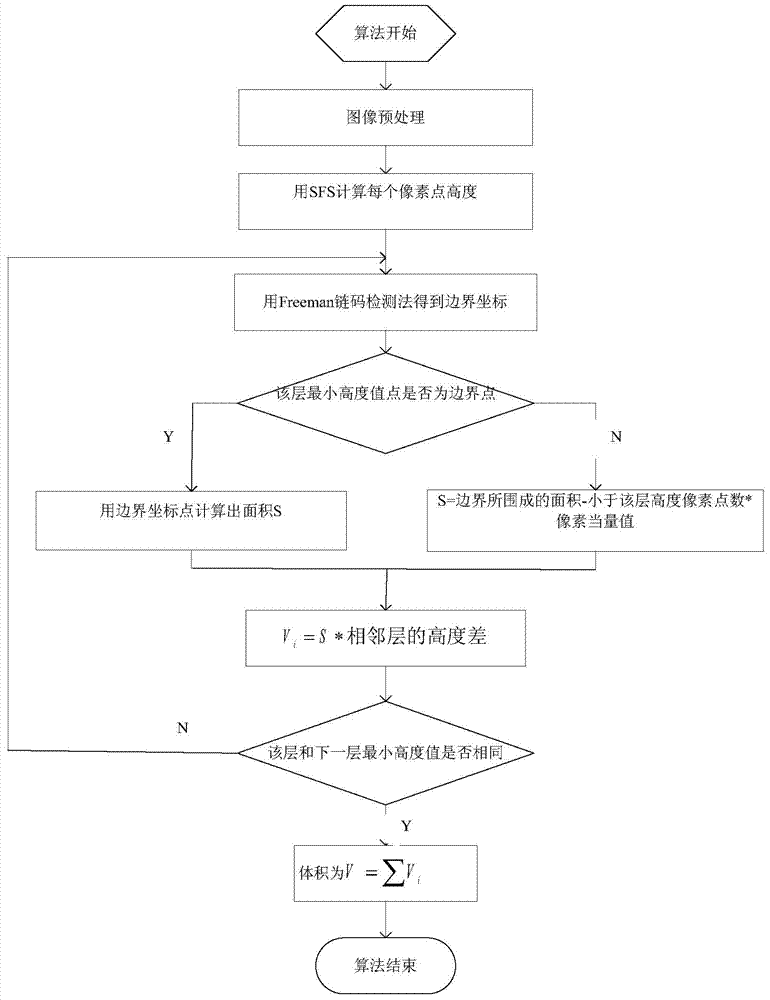

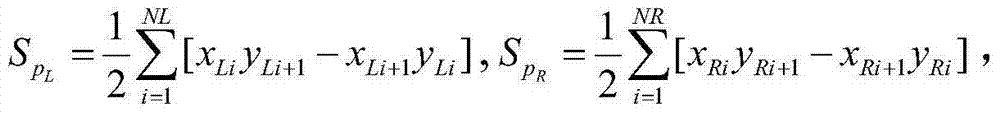

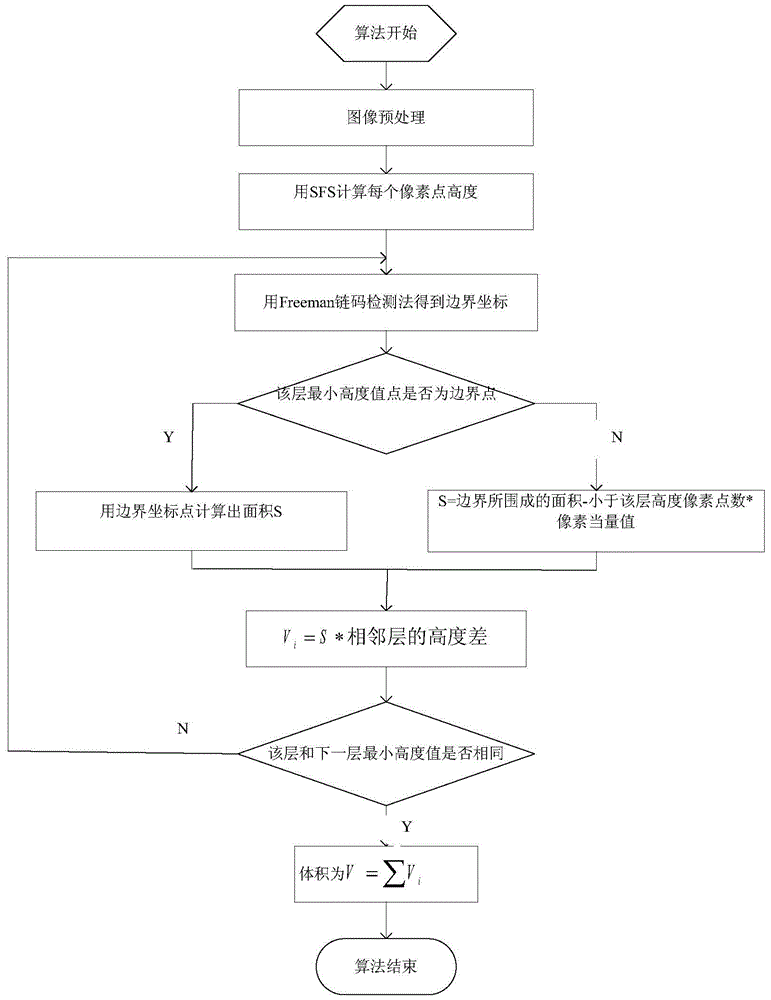

Irregular object volume measurement method based on Freeman chain code detection

The invention discloses an irregular object volume measurement method based on Freeman chain code detection. A system is calibrated so as to acquire a pixel equivalent of the system; three CCD cameras are used for respectively acquiring original images of a to-be-measured object in an over-looking direction, a left-looking direction and a right-looking direction, and maximal peripheral length image coordinate parameters of the to-be-measured object are acquired via the over-looking image; based on the over-looking maximal length pixel number, measurement ranges corresponding to the left-looking image and the right-looking image are divided, a shape from shading method is used for calculating the height of each pixel point of the left-looking image and the right-looking image, a Freeman chain code is used for carrying out boundary detection on the left-looking image and the right-looking image respectively, coordinates of the boundary point are calculated, a Green formula is used for calculating the area surrounded by the boundary, the volume of the first layer is obtained through product between the area and the minimal height value, and the volume of the entire object is finally acquired according to the position of secondary small height value pixel points. The invention provides an accurate non-contact volume measurement method, the measurement speed can be quickened, and the production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

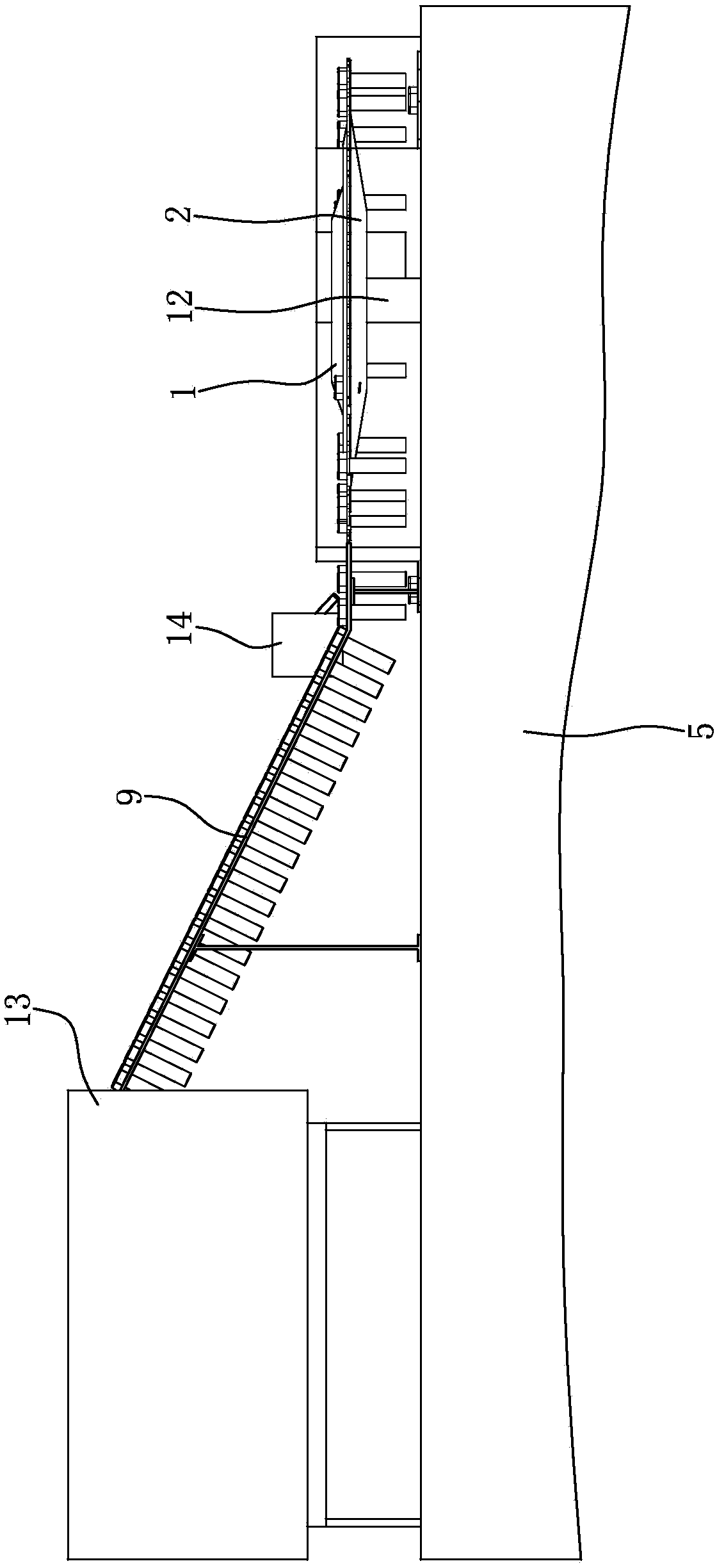

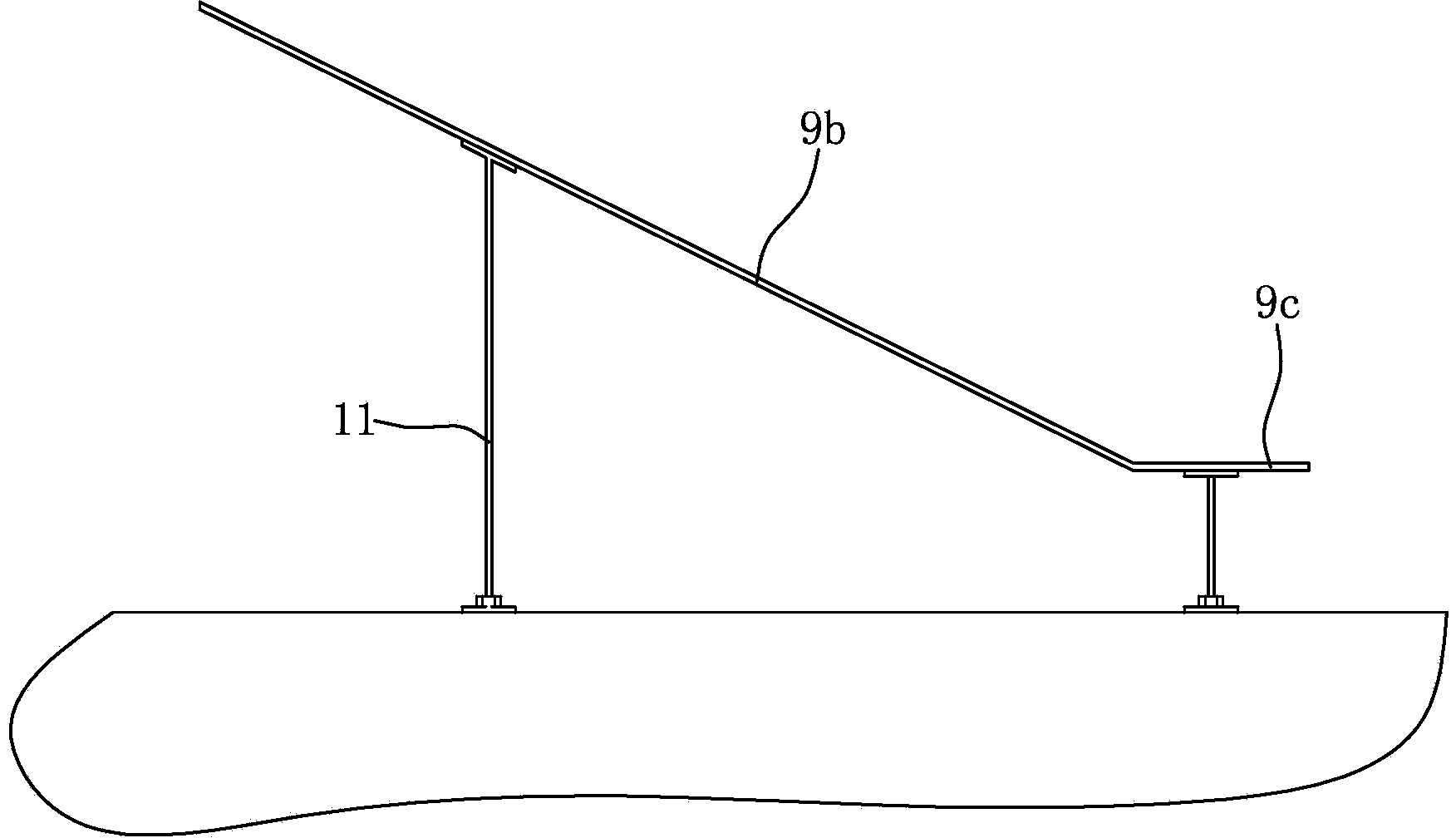

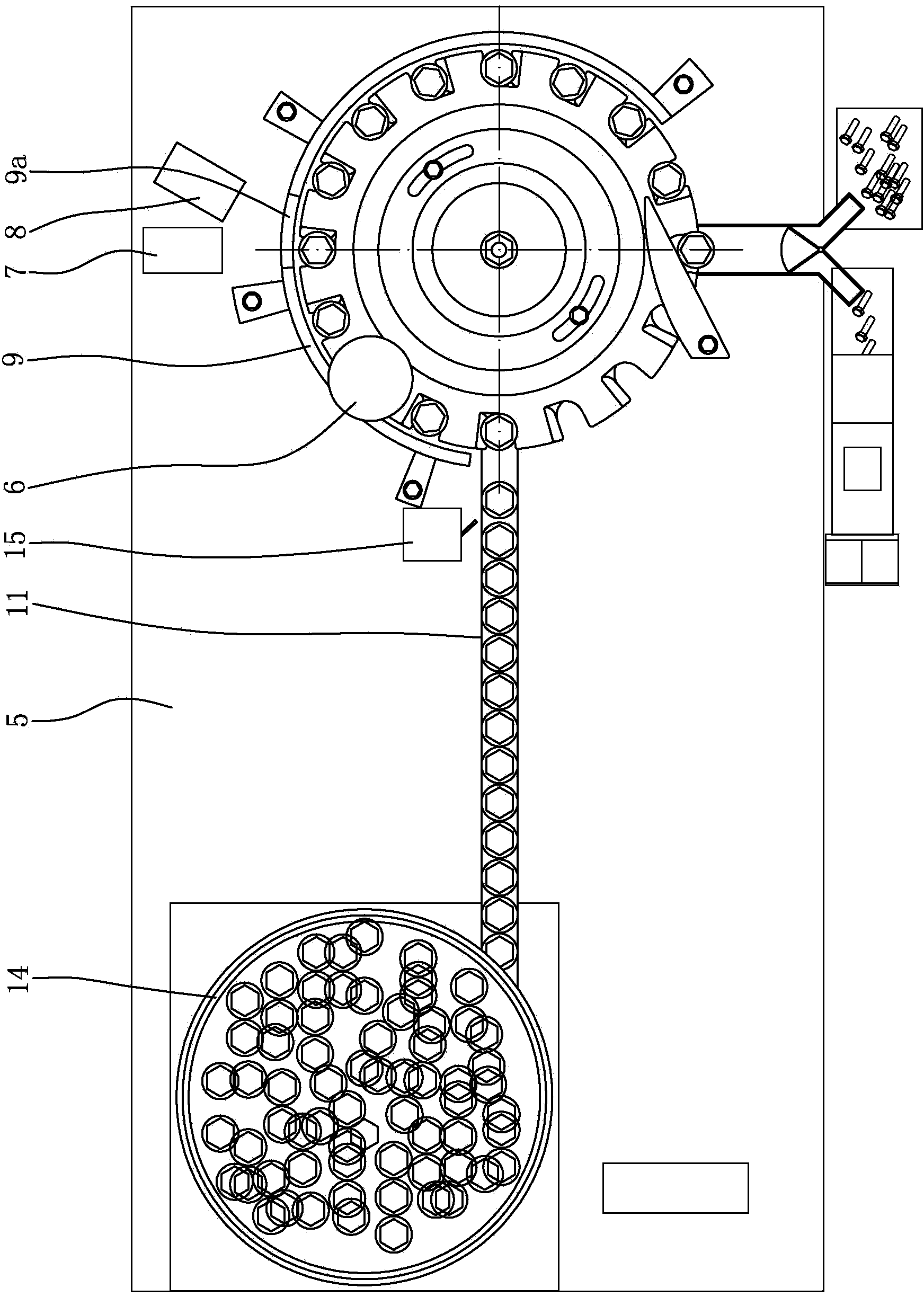

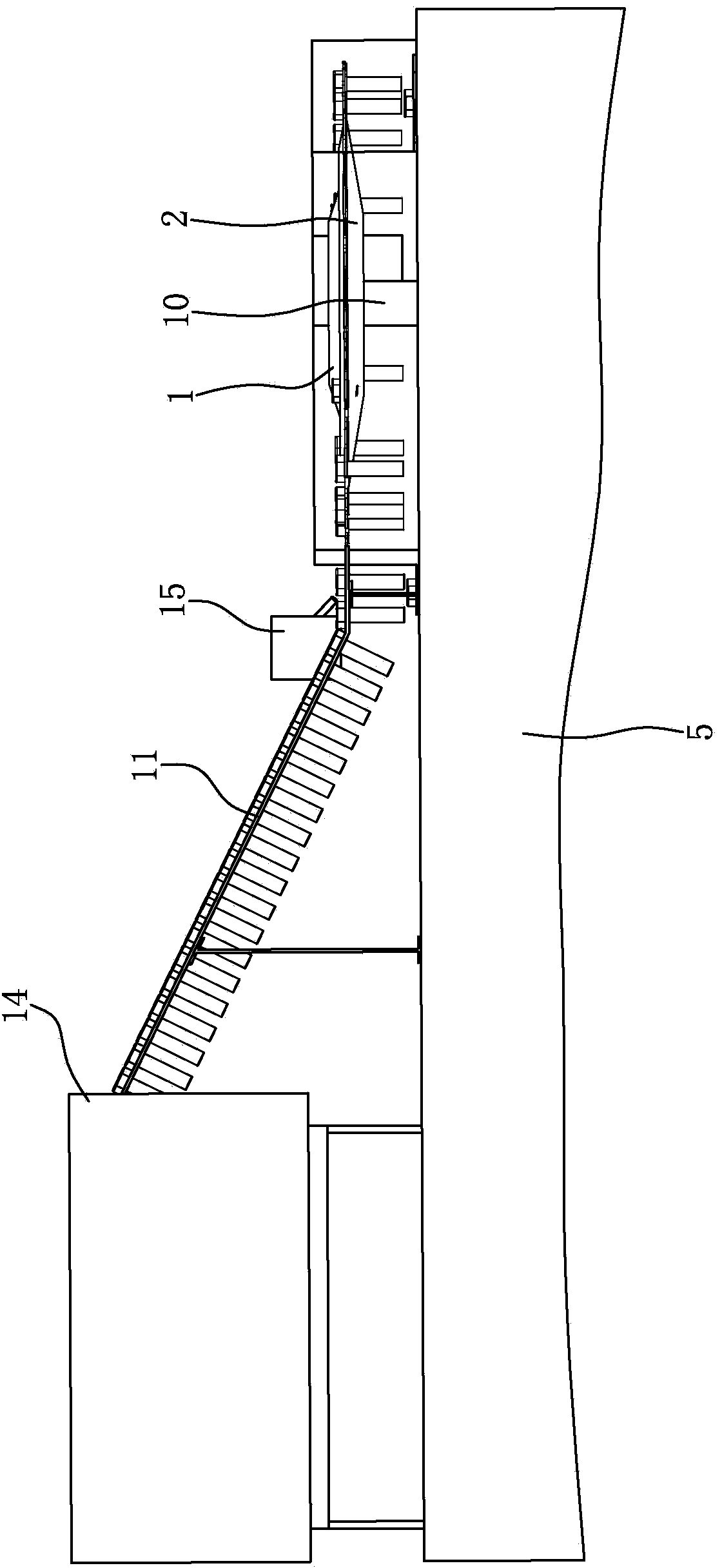

Standard fastener detection conveying and detection device

InactiveCN104142330AOptimize layoutEasy to installOptically investigating flaws/contaminationUsing optical meansEngineeringCcd camera

The invention discloses a standard fastener detection conveying and detection device. An indexing rotary disc is arranged above a machine table (5). A first CCD camera (6) is arranged above the edge of the indexing rotary disc. A second CCD camera (7) and a third CCD camera (8) are arranged near the indexing rotary disc. One side of the indexing rotary disc is provided with a guide rail (9) conveying standard fasteners. The guide rail (9) with the high inlet end and the low outlet end is obliquely arranged. The guide rail (9) is composed of a fixed conveying rail (9a) and an adjustable conveying rail (9b), wherein the fixed conveying rail (9a) and the adjustable conveying rail (9b) are arranged side by side. The standard fastener detection conveying and detection device is simple and compact in structure, small in size, low in cost, capable of taking pictures of the standard fasteners from different angles with the three CCD cameras and being used for detecting the various standard fasteners, suitable for different specifications of parts to be detected, good in universality and high in degree of automation, effectively reduces equipment investment and greatly improves detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

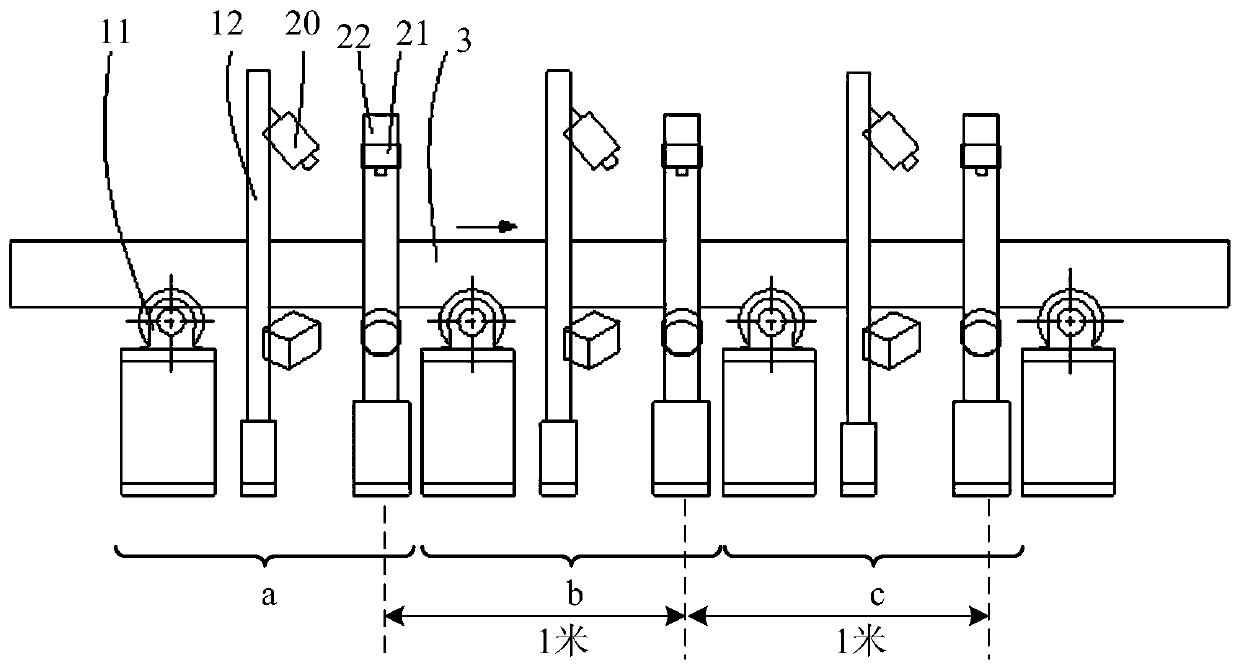

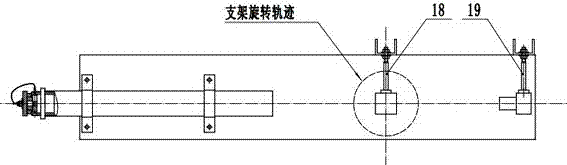

Improved bar straightness detection system and method based on visual detection

InactiveCN110926378AImprove accuracyFree laborImage enhancementImage analysisVision basedEngineering

The invention provides an improved bar straightness detection system based on visual detection. The improved bar straightness detection system comprises three sets of straightness detection devices. The straightness detection device comprises a first annular rack and a second annular rack; three lasers are evenly distributed on the first annular rack, when a bar moves to the first annular rack where the lasers are distributed, lasers emitted by the three lasers surround the circumference of the bar to form a circular ring, and three CCD cameras are evenly distributed on the second annular rack. The distance between every two adjacent sets of straightness detection devices is 1 m, and the three CCD cameras of each set of straightness detection devices shoot three circular ring images formedaround the bar at the same time. Aiming at the problem that the operation process of the bar is not stable, three groups of pictures are shot at the same time, and errors caused by vibration of the bar are avoided in the continuous detection process.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Three-dimensional foot laser scanner

ActiveCN107518522ARealize accurate measurementImproved detection algorithmFoot measurement devicesData processing systemLiquid-crystal display

The invention discloses a three-dimensional foot laser scanner. The three-dimensional foot laser scanner comprises an electromechanical system, an optical system and a data processing system which are connected with one another, wherein the electromechanical system comprises a base and a shell matched with the base; a supporting seat which is connected with a first motor is arranged on the base; a left light engine module is arranged on the left side of the supporting seat; a right light engine module is arranged on the right side of the supporting seat; a lower light engine module is arranged in the middle of the supporting seat; the left light engine module and the right light engine module are symmetrically arranged on the supporting seat; a glass platform is arranged between the front side surface and the rear side surface of the shell, is positioned between the left light engine module and the right light engine module and is positioned over the lower light engine module; and a liquid crystal display screen which is connected with the optical system and the data processing system is arranged above the glass platform. Three lasers and three CCD cameras are adopted, and human body three-dimensional foot laser scanning is realized by laser triangulation; and the measurement precision is high, the integration level is also high, the flexibility is good, and the working efficiency is greatly improved.

Owner:郑州马飞电子技术有限公司

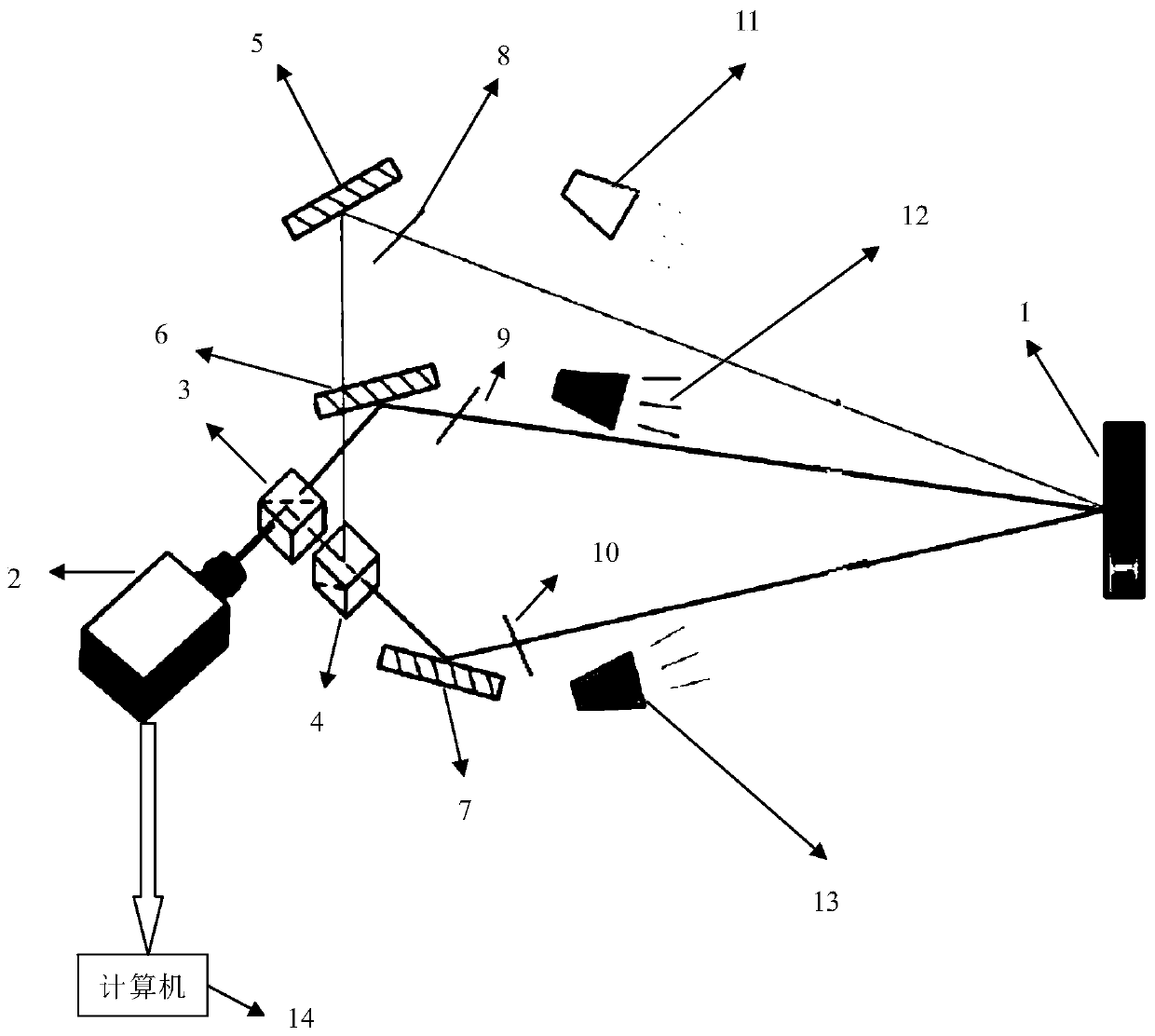

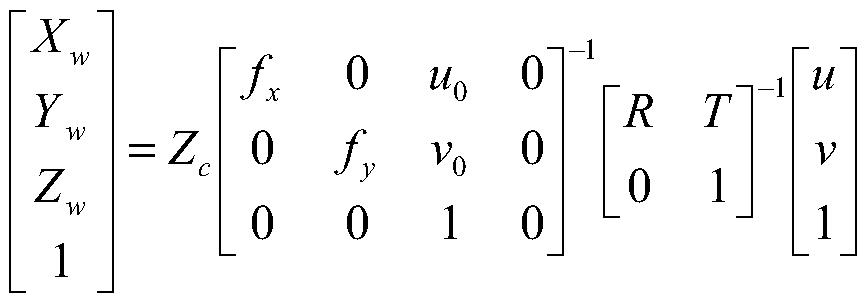

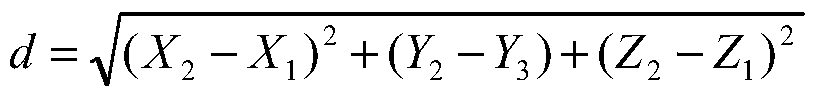

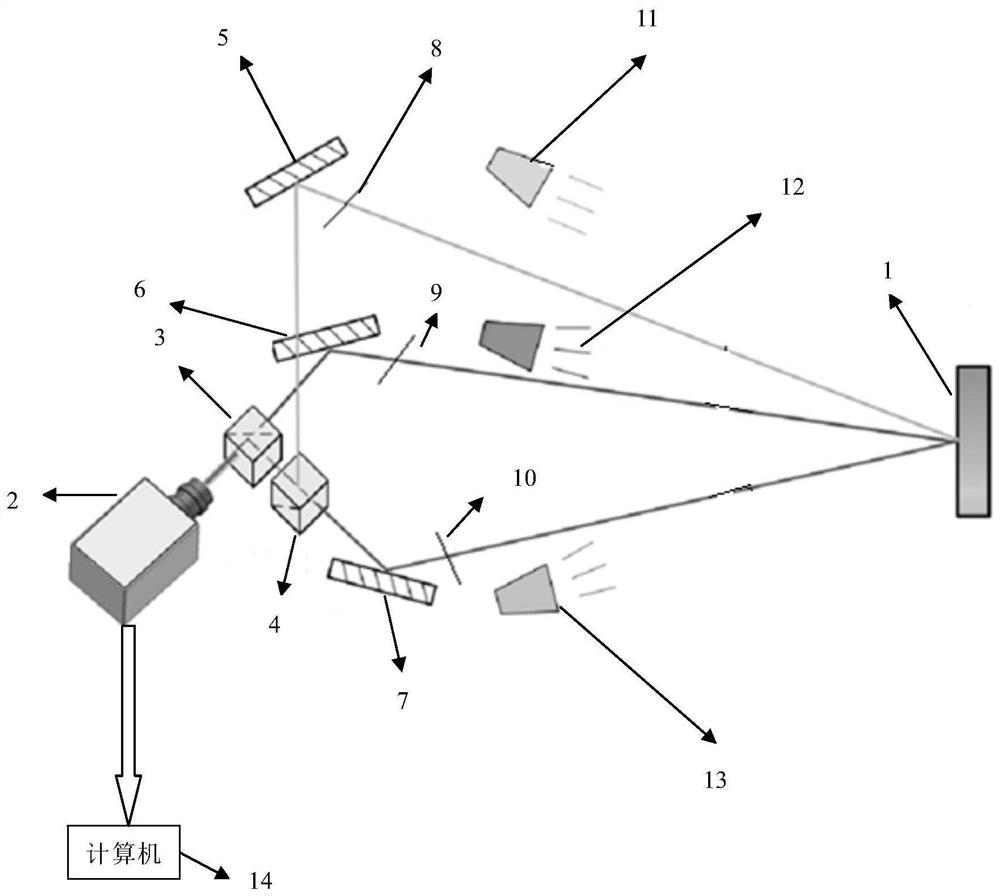

Device and method for image detection of total station bracket accuracy

ActiveCN106979789AImprove work motivationHigh measurement accuracyMechanical clearance measurementsPhotovoltaic energy generationLight spotImage detection

The invention relates to a device for image detection of total station bracket accuracy. The device comprises three CCD cameras, a plane reflector, a holding frame, a concentric gauge, a base and a computer. A measuring method comprises the following steps: on the basis of light reflecting principle, reflecting and forming four circular light spots in light tube CCD cameras by rotating a bracket, and then calculating perpendicularity and parallelism according to the four circular light spots; before and after rotating for 180 degrees, forming two circular light spots in the CCD camera at the top end by a reflecting circle at the top of the concentric gauge and calculating a center distance according to the coordinates of the centers of circle of the two light spots; calculating a distance of the centers of circles of inner and outer diameters of a circle formed in the CCD camera on the other side of the light tube through a circular end face of the concentric gauge and a bracket hole and calculating the coaxial degree of the bracket. According to the invention, an image detection method is adopted, no auxiliary tool is required, the measurement for the precision verticality, parallelism, coaxial degree and center distance of the bracket can be completed by a single person, the stability and the measurement accuracy both can reach u-level and the efficiency is increased.

Owner:SUZHOU XUNWEI PHOTOELECTRIC TECH

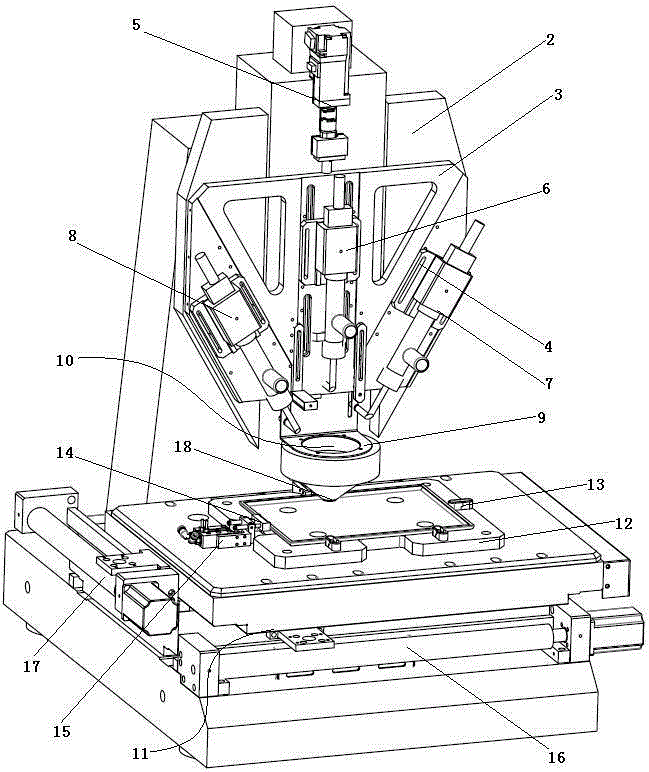

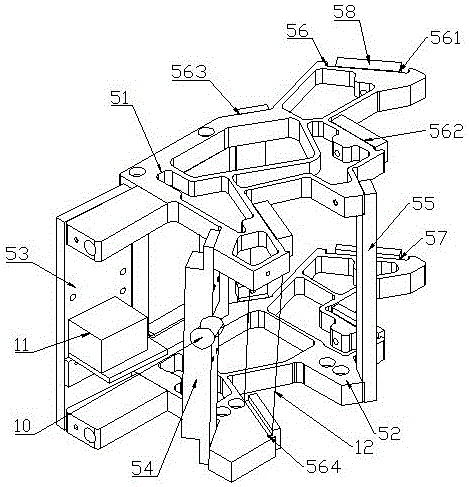

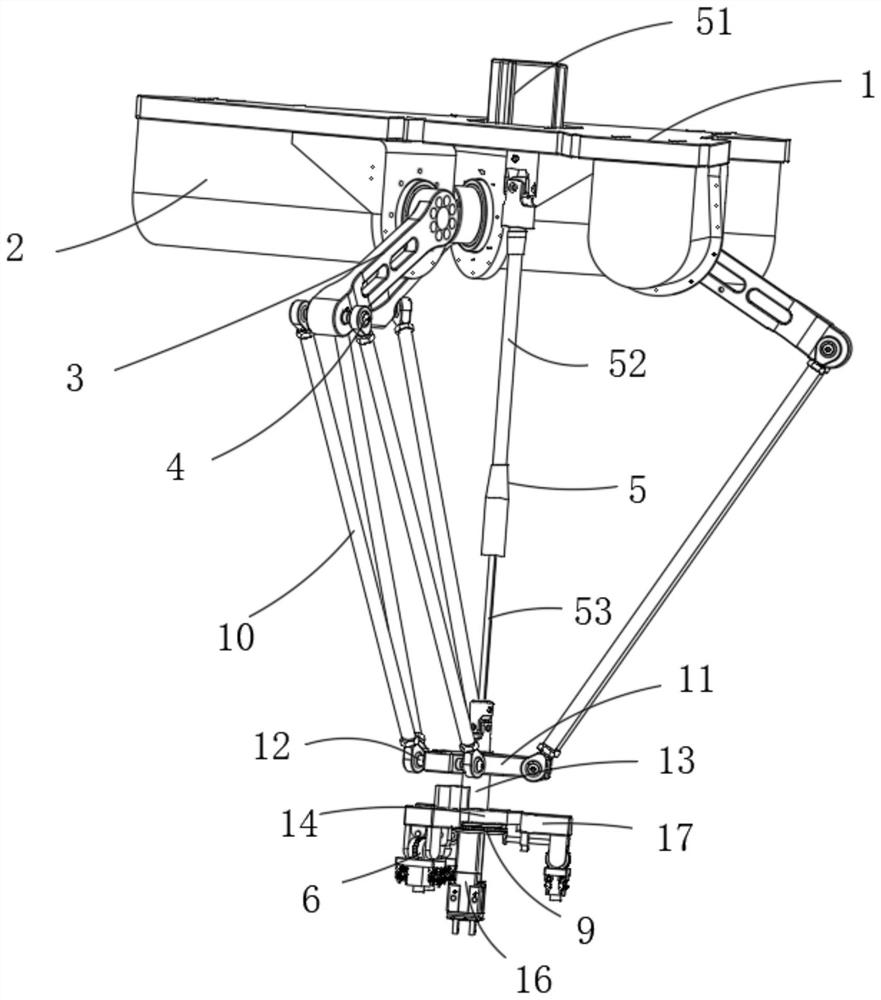

Parallel robot and circular motion trail interpolation method thereof

The invention provides a parallel robot which comprises a first mounting plate, first servo motors, swing arms, first fixing shafts, connecting rods, a fixing table and second fixing shafts; the first servo motors are fixed to the lower surface of the first mounting plate at equal intervals, the swing arms are fixed to the output ends of the first servo motors, and the first fixing shafts are symmetrically fixed to one ends of the swing arms; the first fixing shafts are rotationally connected with the connecting rods through a spherical bearing; and the fixing table is arranged below the first mounting plate, and the second fixing shafts are symmetrically fixed to the three corners of the fixing table. According to the invention, three CCD cameras can carry out omnibearing visual inspection on a workpiece, so that a robot can carry out visual inspection on the workpiece while carrying out feeding and discharging on the workpiece, the working efficiency is greatly improved, and a laser positioner can carry out accurate positioning and clamping on the position of the workpiece, so a driving clamp can accurately clamp the workpiece, the clamping precision is high, and the driving clamp is suitable for positioning and clamping of the special-shaped workpiece.

Owner:广州市新豪精密科技有限公司

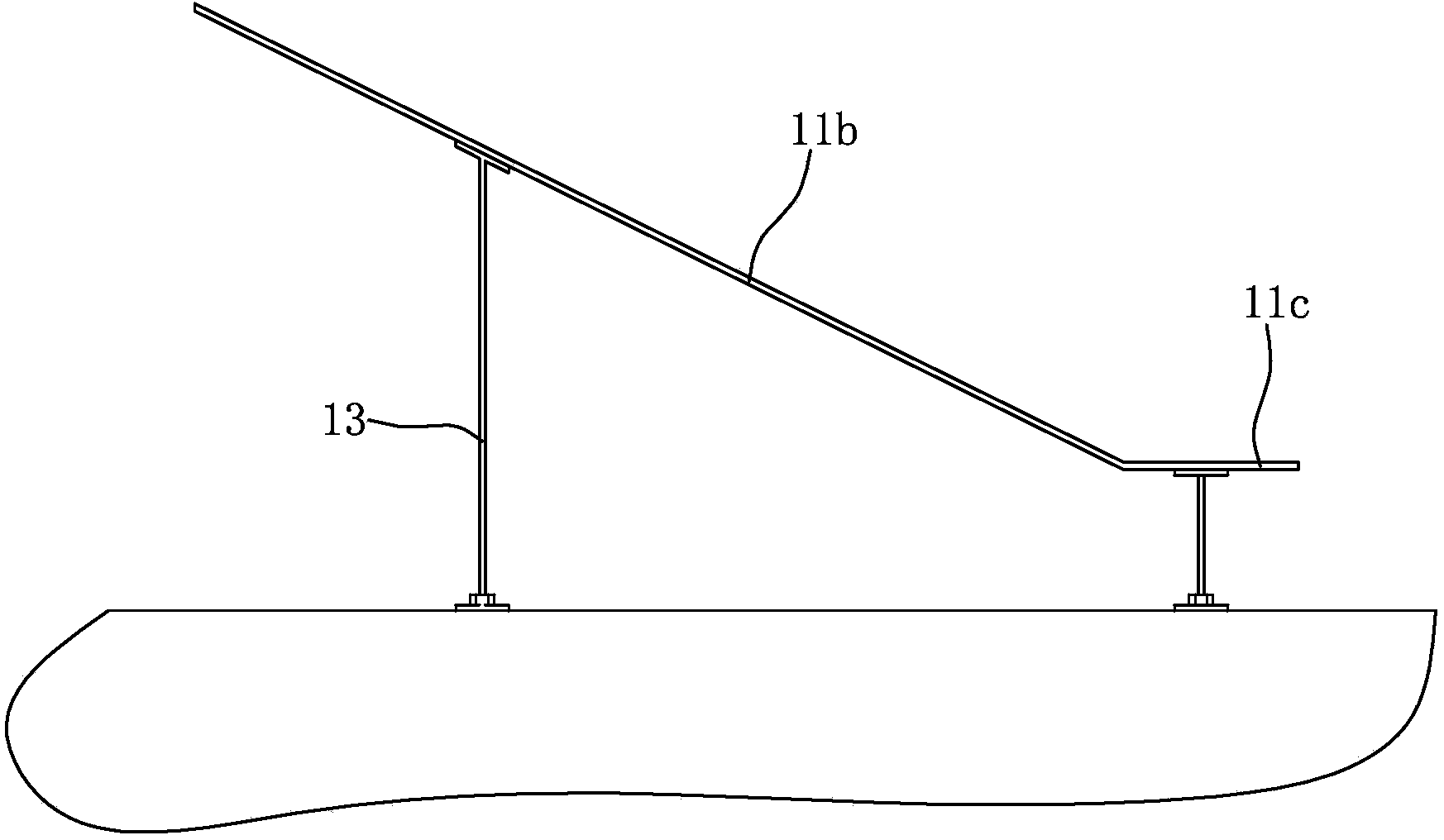

Machine vision detection system

InactiveCN104142344AWon't shakeImprove stabilityOptically investigating flaws/contaminationUsing optical meansMachine visionThree-CCD camera

The invention discloses a machine vision detection system. A vibrating disk (14) is installed at one end of the top of a machine table (5), a rotary indexing disk is arranged at the other end of the top of the machine table (5), guide rails (11) for conveying parts are arranged between the vibrating disk (14) and the rotary indexing disk, the guide rails (11) are obliquely arranged with the inlet ends high and the outlet ends low, both the outlet end of the fixed conveying rail (11a) and the outlet end of the adjustable conveying rail (11b) are bent upward to from horizontal segments (11c), and an air blowing device (15) is arranged on the lateral side of the outlet ends of the guide rails (11). Through the machine vision detection system, parts to be detected can be effectively prevented from disengaging, pictures of the parts can be taken by three CCD cameras from different angles, standard fasteners can be conveyed and detected automatically, the machine vision detection system can be used for detecting various standard fasteners, can adapt to different specifications of parts to be detected and is good in universality and high in automation degree, equipment investment is effectively reduced, and detection efficiency is greatly improved.

Owner:CHONGQING YINGQUAN STANDARD PARTS

Standard fastener visual detection mechanism

InactiveCN104142348AGuaranteed reliabilityEasy to processOptically investigating flaws/contaminationUsing optical meansCcd cameraComputer science

The invention discloses a standard fastener visual detection mechanism. An indexing rotary disc is arranged above a machine table (5). The indexing rotary disc is driven by a stepping motor (10) installed on the machine table (5) to rotate. A first CCD camera (6) is arranged above the edge of the indexing rotary disc. A second CCD camera (7) and a third CCD camera (8) are arranged near the indexing rotary disc. One half of the periphery of the indexing rotary disc is surrounded by a disengagement preventing baffle (9) which is in a circular arc shape, and the two ends of the disengagement preventing baffle (9) and the position close to the middle of the disengagement preventing baffle (9) are fixed to the machine table (5) through a support. The standard fastener visual detection mechanism is simple and compact in structure, small in size, low in cost, capable of effectively preventing parts to be detected from being disengaged and taking pictures of the parts from different angles with the three CCD cameras, capable of being used for detecting the various standard fasteners, suitable for different specifications of parts to be detected and good in universality, effectively reduces equipment investment and greatly improves detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

Spatial displacement and strain measurement device and method based on CCD camera

ActiveCN110595364ACompact structureThe calculation result is accurateUsing optical meansData acquisitionCcd camera

The invention discloses a spatial displacement and strain measurement device and method based on a CCD camera. The spatial displacement and strain measurement device comprises the CCD color camera, afirst spectroscope, a second spectroscope, a first reflector, a second reflector and a third reflector; the first reflector, the first spectroscope and the second spectroscope constitute a first lightpath, the second reflector and the first spectroscope constitute a second light path, and the third reflector, the second spectroscope and the first spectroscope constitute a third light path; the first light path, the second light path and the third light path all enter the CCD color camera; and the CCD color camera is used for conducting shooting through the first light path, the second light path and the third light path. The spatial displacement and strain measurement device is simple in structure, no synchronous trigger device is required for synchronous data acquisition, equivalently, shooting is conducted from three directions with three CCD cameras, thus the calculation result is more accurate, the limitation on the shape of the surface of a to-be-measured object is avoided, and application is flexible.

Owner:GUANGZHOU UNIVERSITY

A device and method for measuring spatial displacement and strain based on CCD camera

ActiveCN110595364BCompact structureThe calculation result is accurateUsing optical meansBeam splitterData acquisition

Owner:GUANGZHOU UNIVERSITY

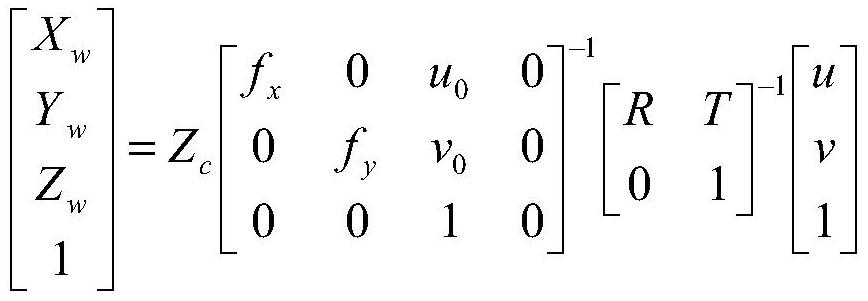

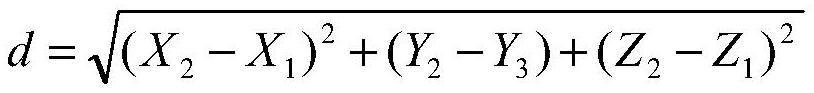

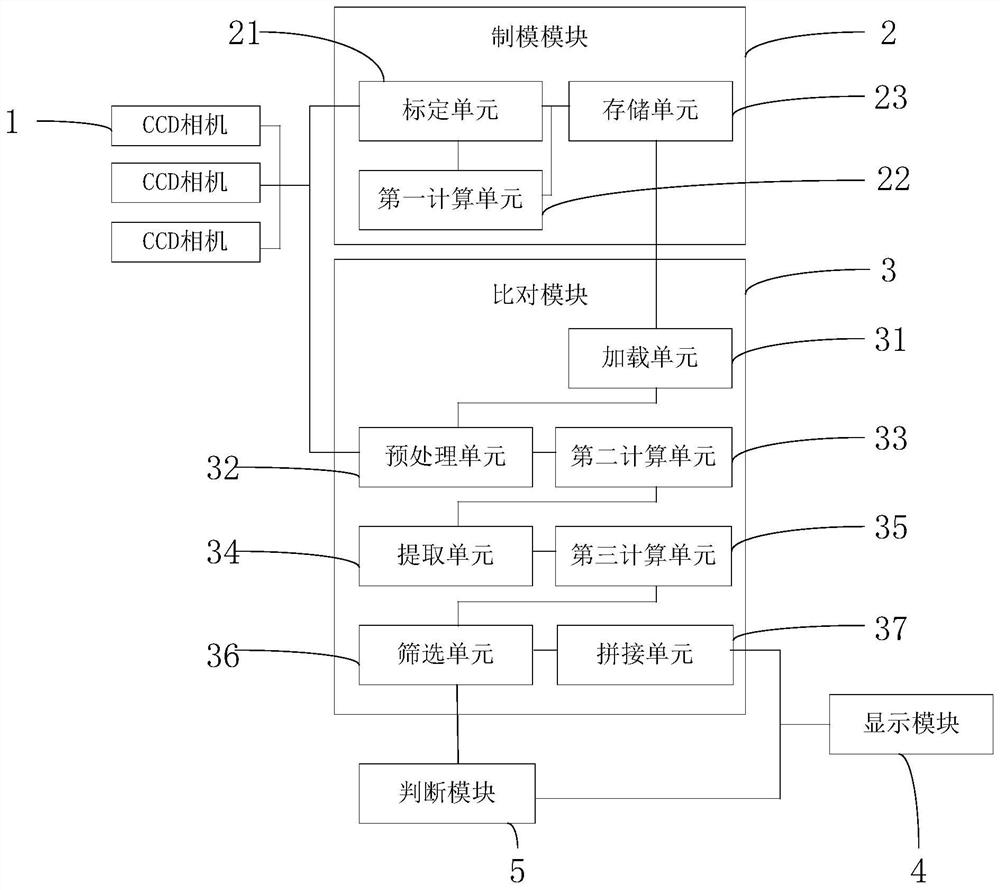

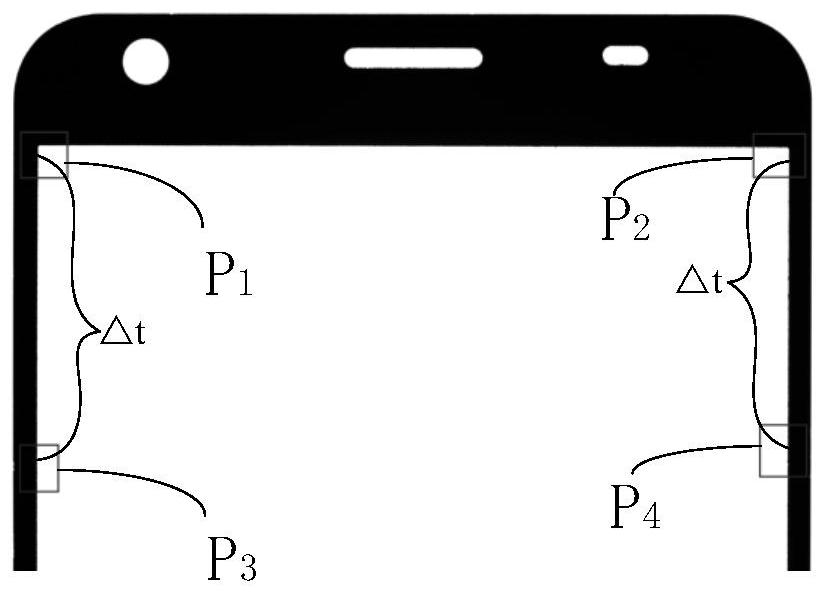

Detection system for rotary disc type glass cover plate screen printing and detection method thereof

ActiveCN113063731AHigh precisionHigh resolutionMaterial analysis by optical meansScreen printingGlass cover

The invention discloses a detection system for rotary disc type glass cover plate screen printing and a detection method thereof, and the system comprises a camera module which comprises three CCD cameras; a molding module which comprises a calibration unit, a first calculation unit and a storage unit, wherein the calibration unit is connected to the three CCD cameras, the first calculation unit and the storage unit, and the first calculation unit is connected to the storage unit; and a comparison module which comprises a loading unit, a preprocessing unit, a second calculation unit, an extraction unit, a third calculation unit and a screening unit, wherein the loading unit is connected to the storage unit, the preprocessing unit is connected to the three CCD cameras, the loading unit, the second calculation unit and the extraction unit, and the third calculation unit is connected to the extraction unit and the screening unit. According to the invention, the problem that a lot of misjudgments exist in the detection of small defects such as sand holes and the like in the traditional wireframe printing detection of the mobile phone glass cover plate is solved.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

A novel detection method and device for alcohol content

ActiveCN104977296BIncrease softnessSimplify the detection and analysis processMaterial analysis by observing effect on chemical indicatorSensor arrayColor changes

Owner:JIANGSU UNIV

A Parallel Robot and Its Circular Motion Trajectory Interpolation Method

The present invention provides a parallel robot, which includes a first mounting plate, a first servo motor, a swing arm, a first fixed shaft, a connecting rod, a fixed platform and a second fixed shaft, and the lower surface of the first mounting plate is equidistantly fixed with A first servo motor, the output end of the first servo motor is fixed with a swing arm, one end of the swing arm is symmetrically fixed with a first fixed shaft, and the first fixed shaft is rotatably connected to a connecting rod through a spherical bearing, and the first fixed shaft is connected to a connecting rod through a spherical bearing. A fixing platform is arranged under the installation plate, and the triangles of the fixing platform are all symmetrically fixed with second fixing shafts. The invention can carry out all-round visual detection on the workpiece through three CCD cameras, so that the robot can visually detect the workpiece while loading and unloading the workpiece, greatly improving the work efficiency, and the position of the workpiece can be checked by the laser positioner Perform precise positioning and clamping, so that the driving fixture can accurately clamp the workpiece, with high clamping accuracy, and is suitable for positioning and clamping of special-shaped workpieces.

Owner:广州市新豪精密科技有限公司

Standard fastener detection device based on machine vision

InactiveCN104142341AThe working process is simple and fastHigh degree of automationOptically investigating flaws/contaminationUsing optical meansMachine visionCcd camera

The invention discloses a standard fastener detection device based on machine vision. A rotary indexing disk is arranged above a machine table (5), a first CCD camera (6) is arranged above the edge of the rotary indexing disk, and a second CCD camera (7) and a third CCD camera (8) are arranged beside the rotary indexing disk; an anti-disengagement baffle (9) surrounds half of the periphery of the rotary indexing disk; a slide way (10) used for receiving parts is further arranged beside the rotary indexing disk, the slide way (10) is fixedly installed on the machine table (5), and a separation shifting fork (11) for shifting parts to the slide way (10) is arranged beside the inlet end of the slide way (10). According to the standard fastener detection device based on machine vision, the pictures of parts can be taken through the three CCD cameras from different angles, the standard fastener detection device based on machine vision can be used for detecting various standard fasteners, and while the standard fasteners are prevented from disengaging, the standard fastener detection device based on machine vision can adapt to different specifications of parts to be detected and has the advantages of being simple and compact in structure, small in size, low in cost, good in universality, high in detection efficiency and the like.

Owner:CHONGQING YINGQUAN STANDARD PARTS

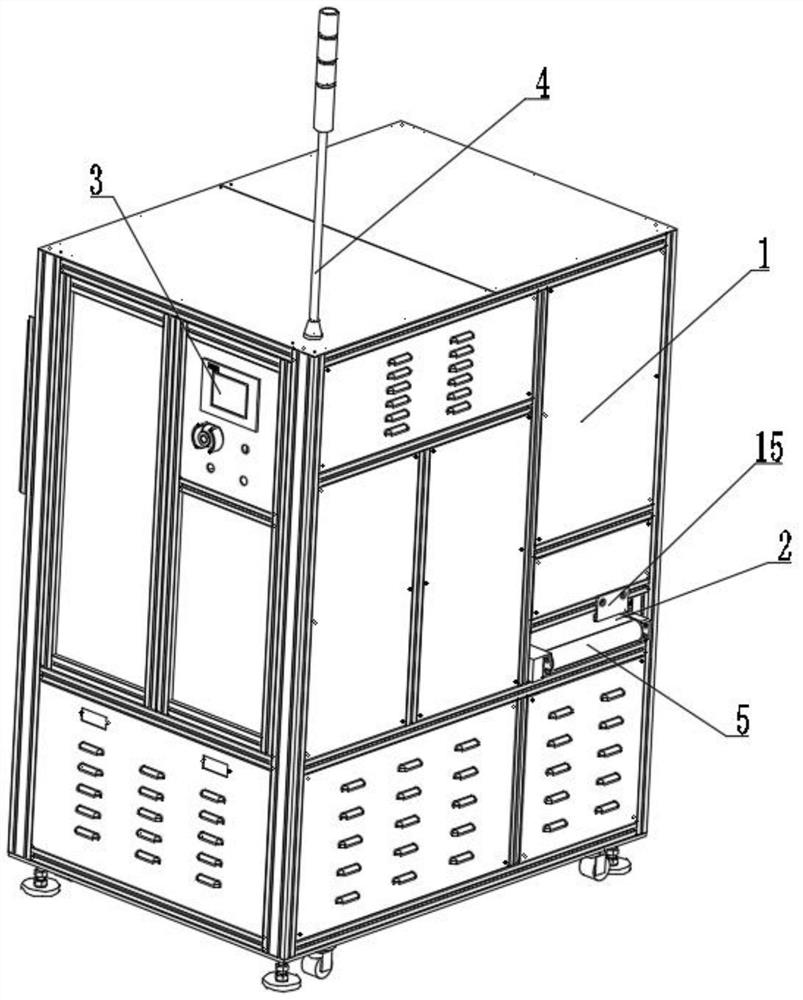

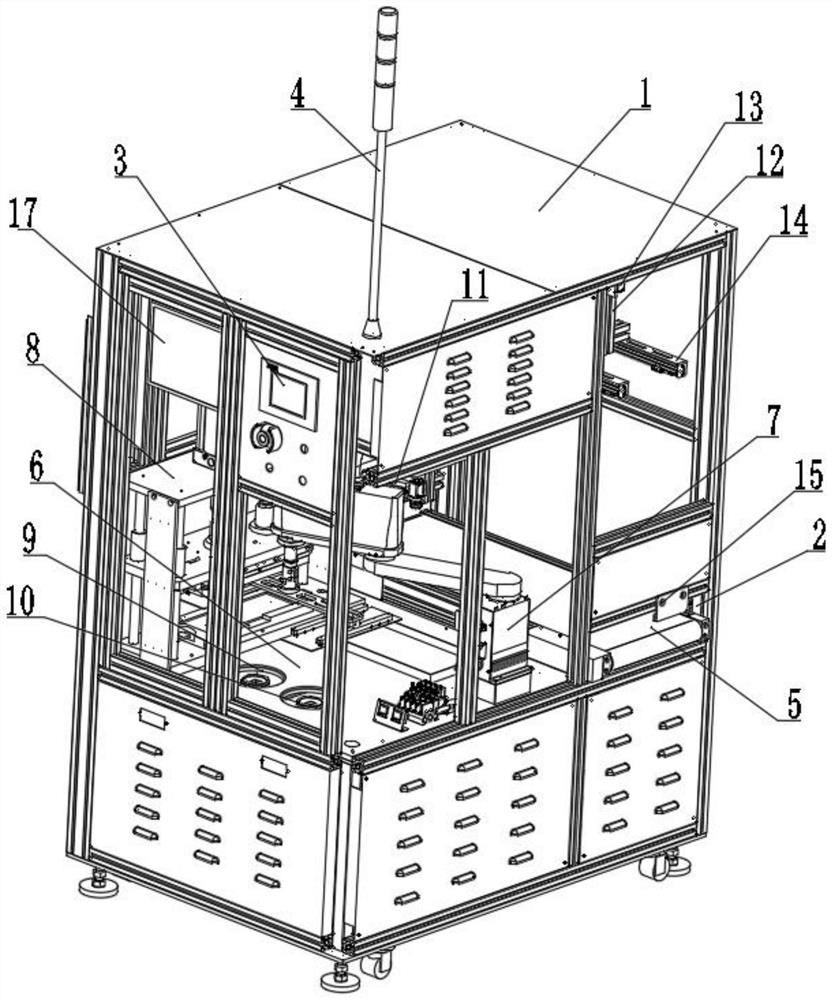

Automatic keyboard film pressing method

PendingCN113410082AImprove efficiencyRealize automatic pressing operationElectric switchesEngineeringCcd camera

The invention relates to the technical field of keyboard films, in particular to an automatic keyboard film pressing device and a using method thereof. The automatic keyboard film pressing device comprises a machine body, a three-color lamp is fixedly connected to the top of the machine body, a feeding port is formed in the front portion of the machine body, a feeding sensor is fixedly connected to the position, above the feeding port, of the machine body, and a conveying belt is arranged in the machine body; a fixed plate is fixedly connected to the interior of the machine body, a first CCD camera and a second CCD camera are fixedly connected to the fixing plate, a pressing device is arranged in the machine body, and a material taking device is fixedly installed in the machine body. According to the automatic keyboard film pressing device and the using method thereof, the keyboard film is shot, positioned and precisely positioned through the three CCD cameras, so the mechanical arm can directly and automatically take, calibrate, feed and transfer the keyboard film, the overall manual labor intensity is reduced, and the keyboard film can be accurately pressed through shooting calibration of the CCD cameras, so the conditions of inclination and inaccurate placement of angle positions in the pressing process are avoided.

Owner:苏州浚泰精密机械有限公司

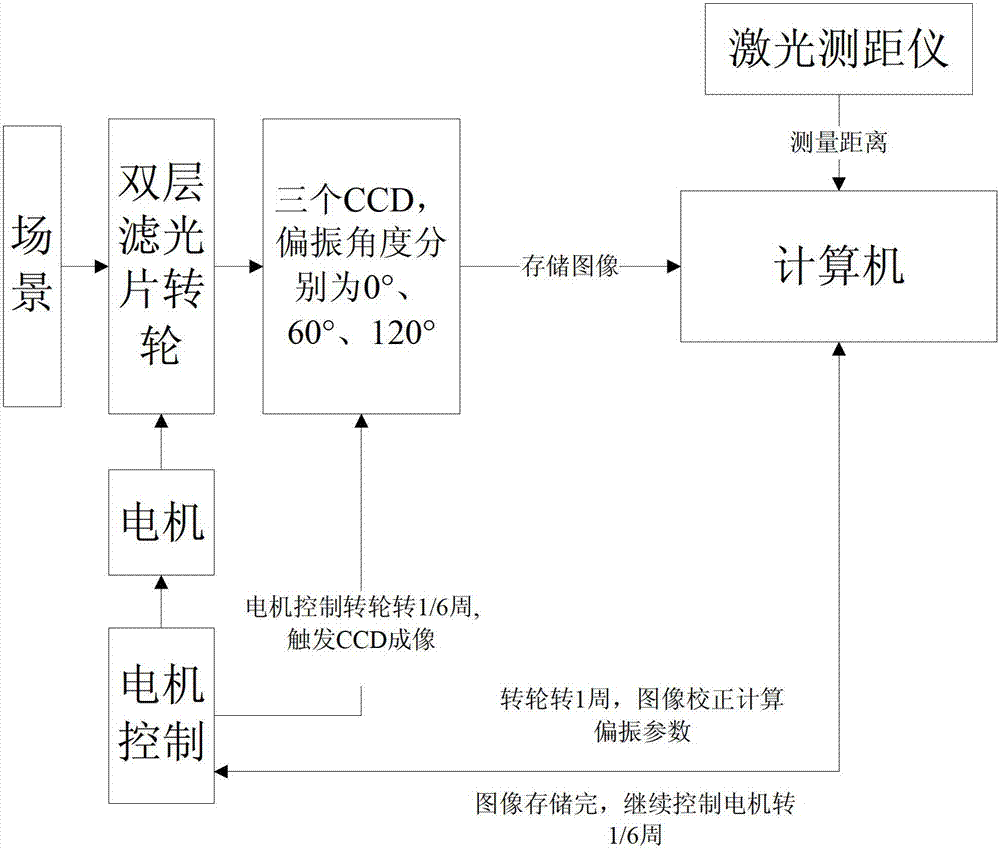

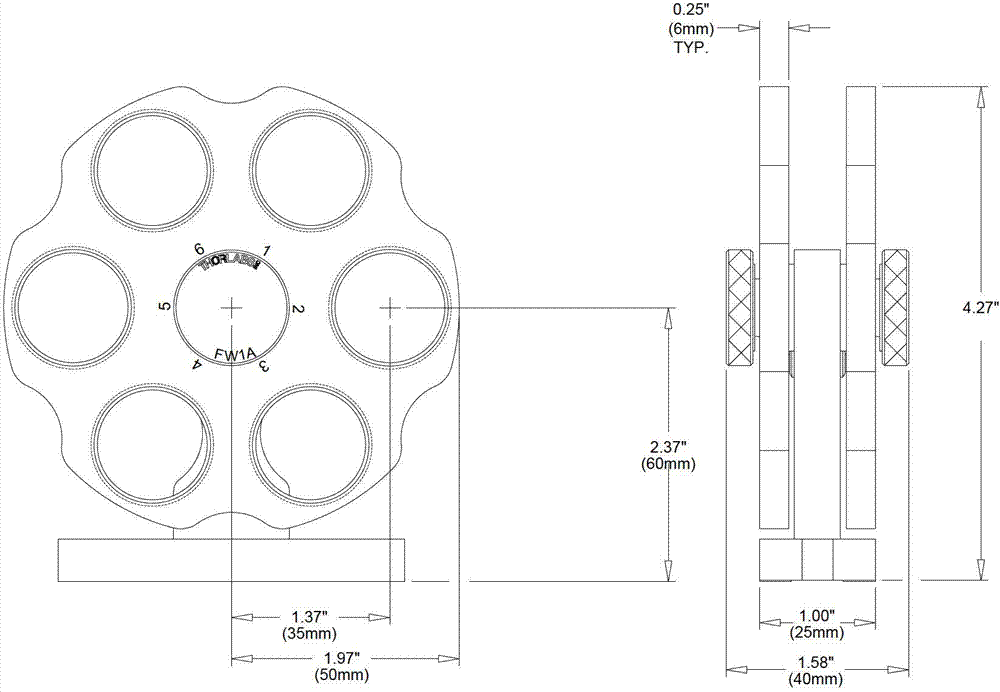

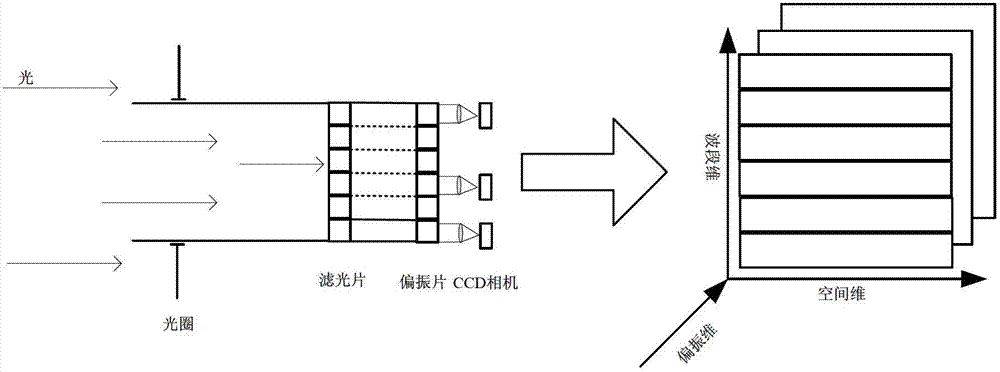

Small multiband polarization imaging system with automatic filter wheel

InactiveCN102809431BImprove detection abilityCompact structurePolarisation spectroscopyLight polarisation measurementCcd cameraOptical polarization

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A volume measurement method for irregular objects based on freeman chain code detection

The invention discloses an irregular object volume measurement method based on Freeman chain code detection. A system is calibrated so as to acquire a pixel equivalent of the system; three CCD cameras are used for respectively acquiring original images of a to-be-measured object in an over-looking direction, a left-looking direction and a right-looking direction, and maximal peripheral length image coordinate parameters of the to-be-measured object are acquired via the over-looking image; based on the over-looking maximal length pixel number, measurement ranges corresponding to the left-looking image and the right-looking image are divided, a shape from shading method is used for calculating the height of each pixel point of the left-looking image and the right-looking image, a Freeman chain code is used for carrying out boundary detection on the left-looking image and the right-looking image respectively, coordinates of the boundary point are calculated, a Green formula is used for calculating the area surrounded by the boundary, the volume of the first layer is obtained through product between the area and the minimal height value, and the volume of the entire object is finally acquired according to the position of secondary small height value pixel points. The invention provides an accurate non-contact volume measurement method, the measurement speed can be quickened, and the production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

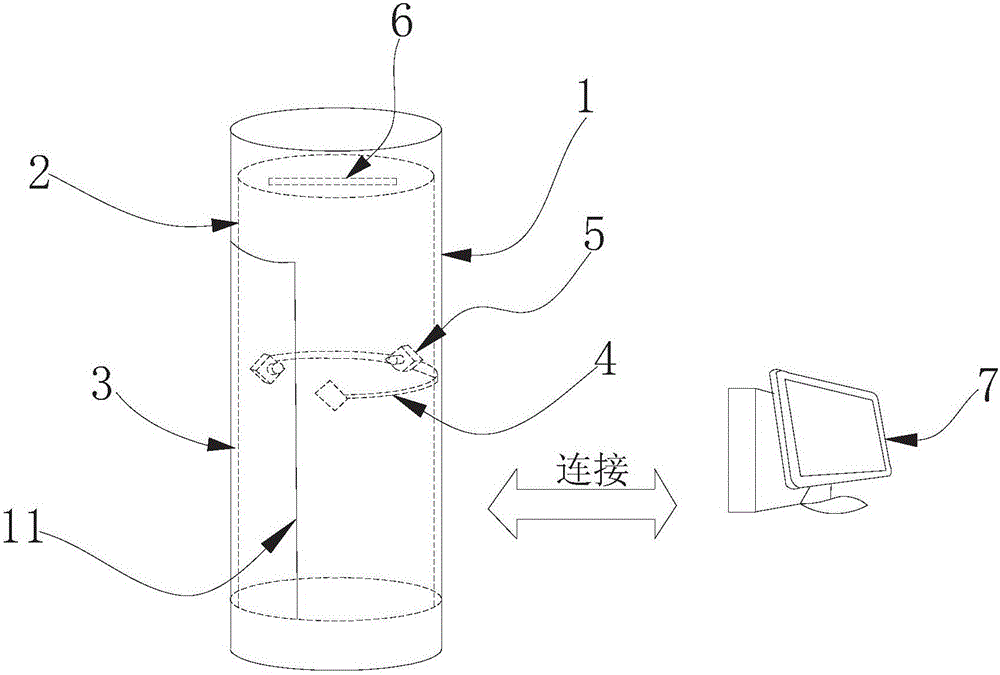

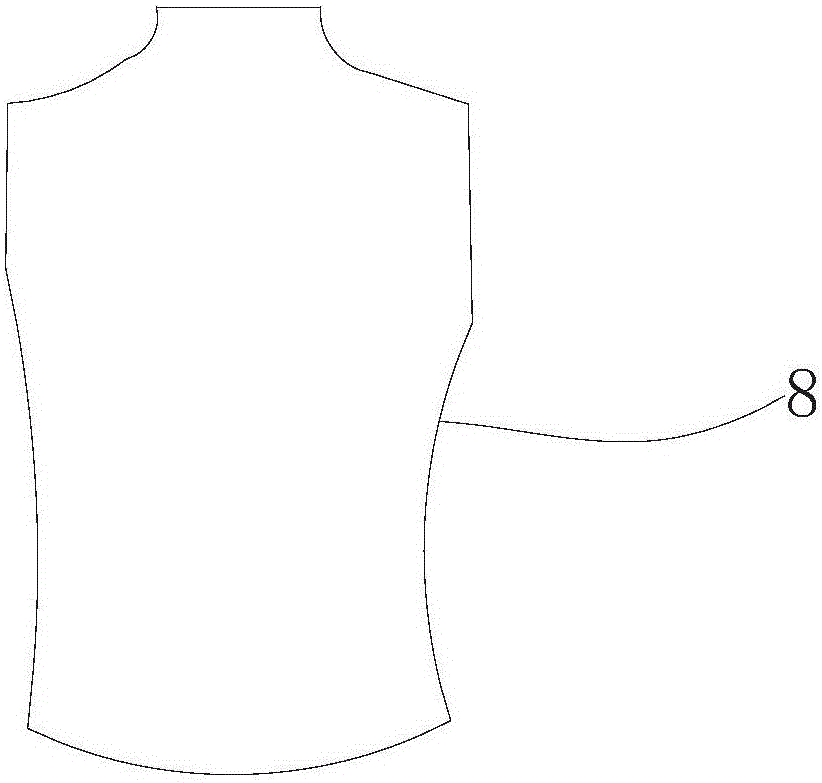

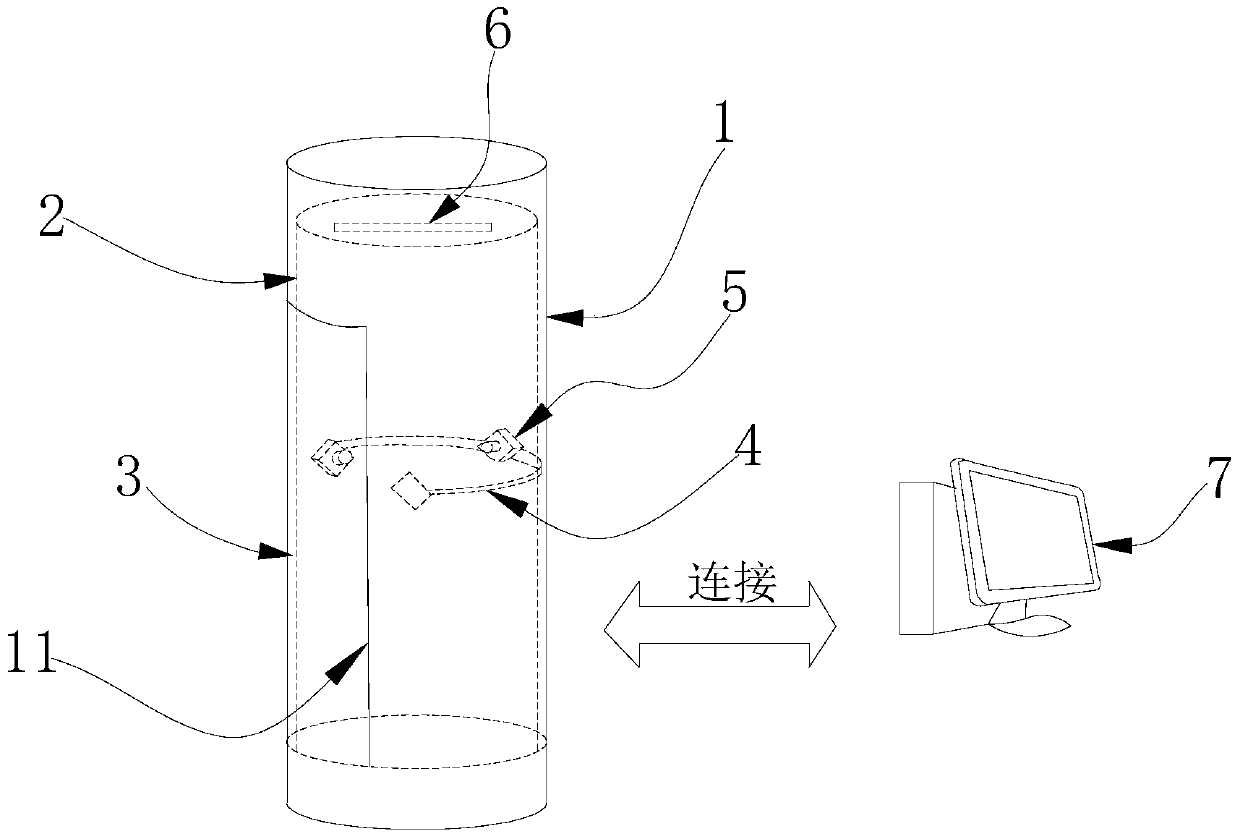

Medical nuclide imaging system and method based on photosensitive tights

InactiveCN105054955AIncrease elasticityReduce complexityRadiation diagnosticsLight equipmentFluorescence

The invention discloses a medical nuclide imaging system and a medical nuclide imaging method based on photosensitive tights. The imaging system comprises an imaging darkroom, three CCD cameras, a control system, a lifting system and the photosensitive tights, wherein the photosensitive tights are prepared by uniformly mixing acrylic fibers and Gd2S2O (gadolinium oxysulfide) rare earth material. During the imaging process, a to-be-tested person receives intravenous injection of corresponding radionuclide, then enters the imaging darkroom for imaging at the proper moment, after lighting equipment inside the imaging darkroom is turned on, the to-be-tested person stands in an imaging area, and the three CCD cameras photograph the to-be-tested person; then the to-be-tested person stands still, the lighting equipment inside the imaging darkroom is turned off, the three CCD cameras collect fluorescence signals converted by the photosensitive tights and on the body surface of the to-be-tested person, and finally a fluorescence signal image and a picture image are displayed in a mixing manner. With the adoption of the medical nuclide imaging system and the medical nuclide imaging method, optical imaging of the medical radionuclide is realized, and the medical nuclide imaging system and the medical nuclide imaging method have the characteristics of whole body imaging, real-time imaging, simplicity and convenience in operation, low cost, and the like.

Owner:XIDIAN UNIV +1

Standard fastener detection device

The invention discloses a standard fastener detection device. An indexing rotary disc is arranged above a machine table (5). The indexing rotary disc is driven by a stepping motor (9) installed on the machine table (5) to rotate. A first CCD camera (6) is arranged above the edge of the indexing rotary disc. A lens of the first CCD camera (6) is downward. A second CCD camera (7) and a third CCD camera (8) are arranged near the indexing rotary disc. The second CCD camera (7) is close to the third CCD camera (8). A lens of the second CCD camera (7) and a lens of the third CCD camera (8) face the indexing rotary disc. The standard fastener detection device is simple and compact in structure, small in size, low in cost, capable of taking pictures of standard fasteners from different angles with the three CCD cameras and being used for detecting the various standard fasteners, suitable for different specifications of parts to be detected and good in universality, effectively reduces equipment investment and greatly improves detection efficiency.

Owner:CHONGQING YINGQUAN STANDARD PARTS

A medical nuclide imaging system and imaging method based on photosensitive tights

InactiveCN105054955BIncrease elasticityReduce complexityRadiation diagnosticsLight equipmentFluorescence

The invention discloses a medical nuclide imaging system and a medical nuclide imaging method based on photosensitive tights. The imaging system comprises an imaging darkroom, three CCD cameras, a control system, a lifting system and the photosensitive tights, wherein the photosensitive tights are prepared by uniformly mixing acrylic fibers and Gd2S2O (gadolinium oxysulfide) rare earth material. During the imaging process, a to-be-tested person receives intravenous injection of corresponding radionuclide, then enters the imaging darkroom for imaging at the proper moment, after lighting equipment inside the imaging darkroom is turned on, the to-be-tested person stands in an imaging area, and the three CCD cameras photograph the to-be-tested person; then the to-be-tested person stands still, the lighting equipment inside the imaging darkroom is turned off, the three CCD cameras collect fluorescence signals converted by the photosensitive tights and on the body surface of the to-be-tested person, and finally a fluorescence signal image and a picture image are displayed in a mixing manner. With the adoption of the medical nuclide imaging system and the medical nuclide imaging method, optical imaging of the medical radionuclide is realized, and the medical nuclide imaging system and the medical nuclide imaging method have the characteristics of whole body imaging, real-time imaging, simplicity and convenience in operation, low cost, and the like.

Owner:XIDIAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com