Parallel robot and circular motion trail interpolation method thereof

A robot and parallel technology, applied in the direction of instruments, digital control, control/adjustment systems, etc., can solve the problems of reducing work efficiency, increasing processes, and easily damaged workpieces, and achieve the effect of improving work efficiency and high clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

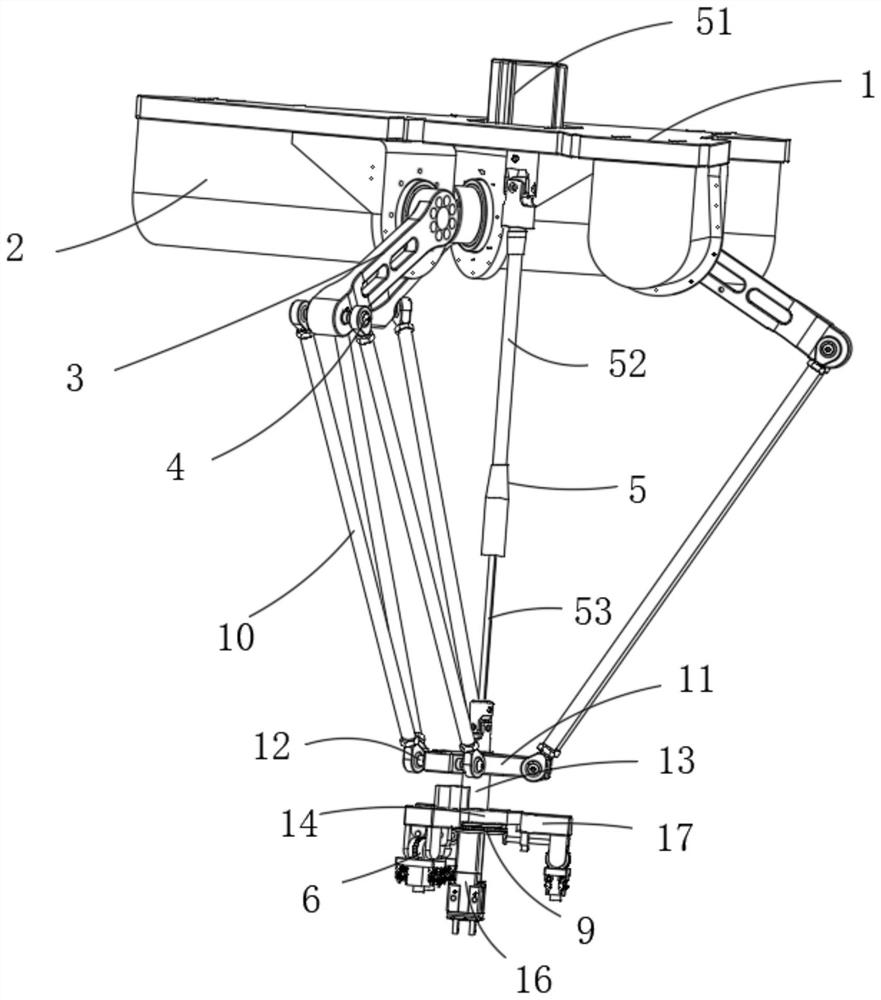

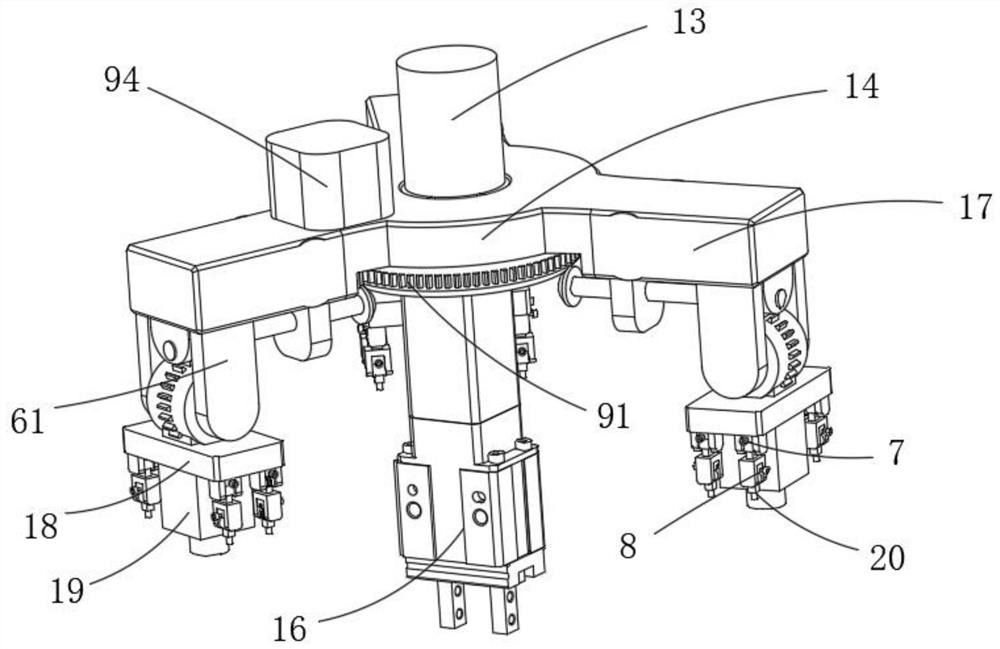

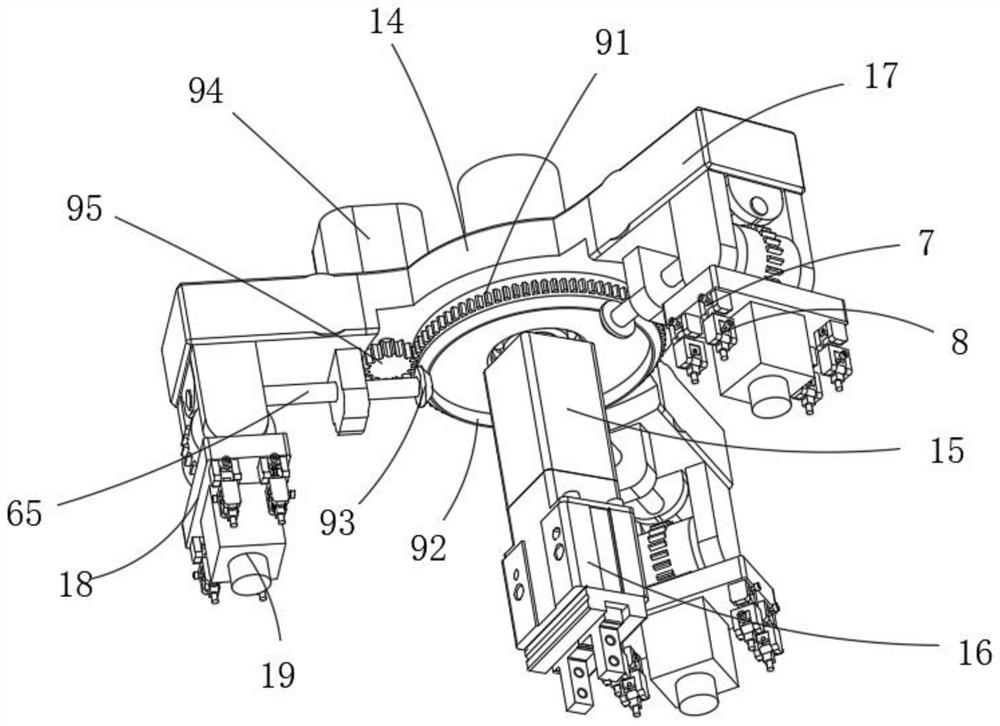

[0042] Please refer to Figure 1-10 ,in, figure 1 A schematic diagram of the overall structure provided for the present invention; figure 2 Schematic diagram of the connection block structure provided by the present invention; image 3 Structural schematic diagram of the driving mechanism provided for the present invention; Figure 4 One of the structural schematic diagrams of the first angle adjustment mechanism provided by the present invention; Figure 5 The second schematic diagram of the structure of the first angle adjustment mechanism provided by the present invention; Figure 6 Schematic diagram of the structure of the second angle adjustment mechanism provided by the present invention; Figure 7 Schematic diagram of the structure of the third angle adjustment mechanism provided by the present invention; Figure 8 Schematic diagram of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com