Device and method for image detection of total station bracket accuracy

A technology of image detection and total station, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of detection methods that cannot meet the needs, high cost, accuracy of measurement results, poor repeatability, etc., to improve workers Improvement of work motivation and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

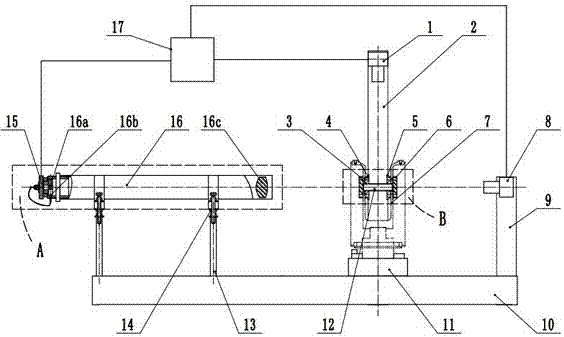

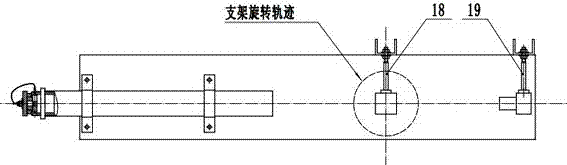

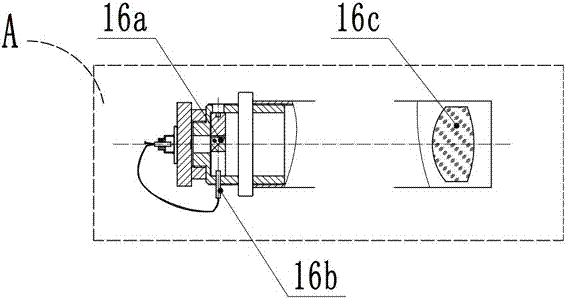

[0030] In order to enable those skilled in the art to understand the present invention more accurately and implement the present invention better, the reference numerals are described in detail below in conjunction with the accompanying drawings, and the names of components corresponding to the reference numerals in the accompanying drawings are as follows:

[0031] 1—top CCD camera, 2—support frame, 3—first plane mirror, 4—first cage, 5—second cage, 6—second plane mirror, 7—bracket, 8—side CCD Camera, 9—short support frame, 10—base, 11—base, 12—concentric gauge, 13—support column, 14—nut screw assembly, 15—light tube CCD camera, 16—light tube, 16a—right-angle prism, 16b—optical fiber, 16c—lens, 17—computer, 18—first connecting rod, 19—second connecting rod.

[0032] please see Figure 1 to Figure 4 , Figure 6, a device for image detection of total station support accuracy, comprising: a top CCD camera 1, a first plane mirror 3, a first holder 4, a second holder 5, a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com