Standard fastener detection conveying and detection device

A technology for standard fasteners and detection devices, which is applied in the direction of measuring devices, optical devices, and optical testing for flaws/defects, etc. It can solve the problems of inability to detect thread pitches, fewer detection mechanisms, and narrow adaptation ranges, and achieve easy processing and production , easy adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

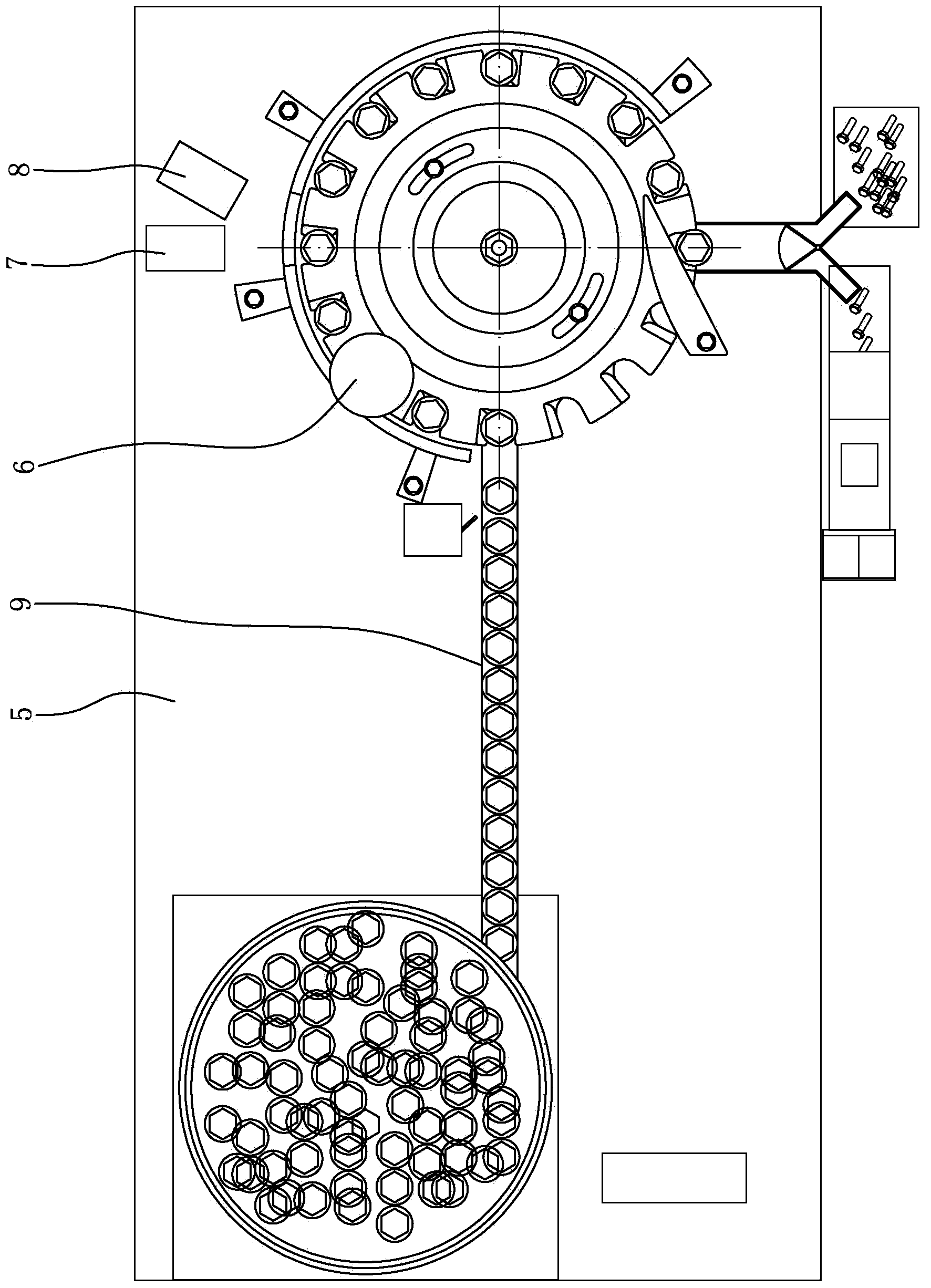

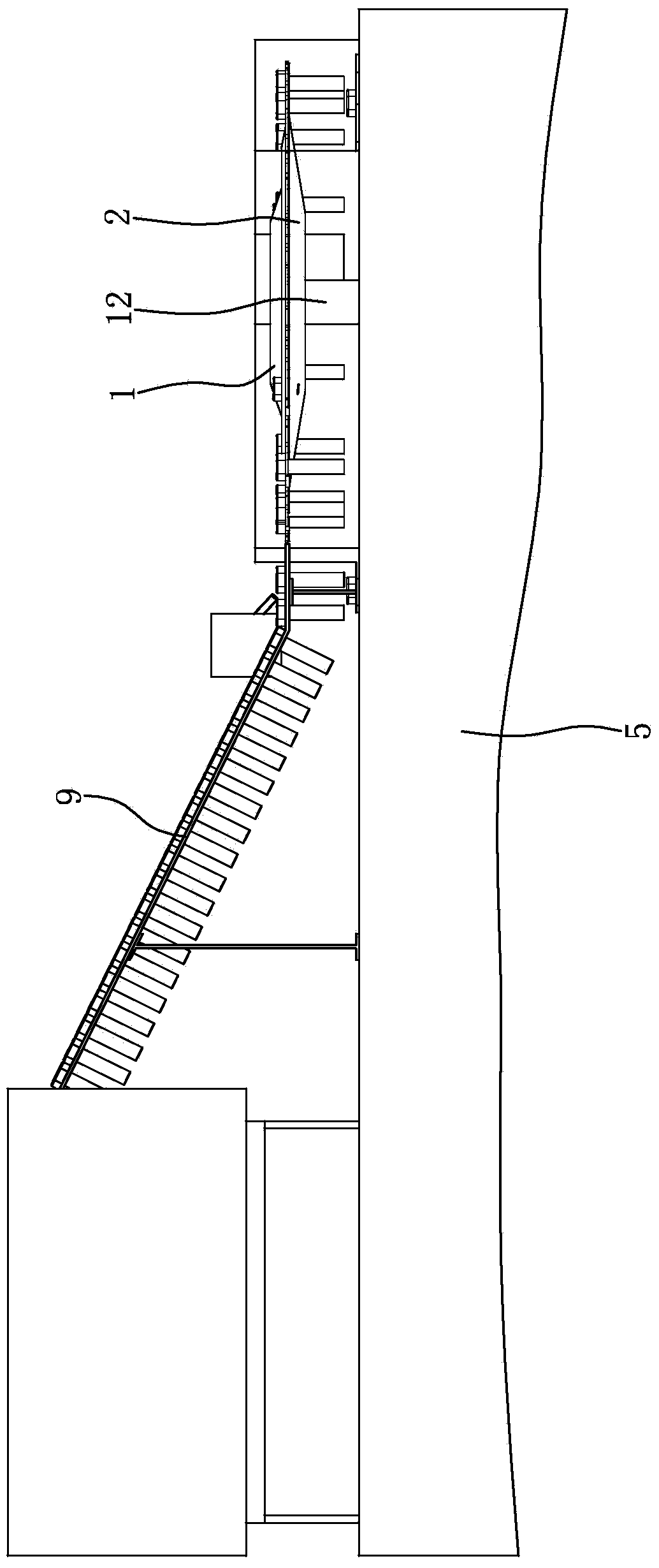

[0033] Such as figure 1 , figure 2 , Figure 5As shown, the indexing turntable is arranged on the machine platform 5 and consists of a moving plate 1 and a fixed plate 2 . The first CCD camera 6 is arranged above the edge of the indexing turntable, and the lens of the first CCD camera 6 faces downwards, and the second CCD camera 7 and the third CCD camera 8 are set beside the indexing turntable, and the second CCD The camera 7 is close to the third CCD camera 8, and there is an angle of about 30° between the second CCD camera 7 and the third CCD camera 8, and the lenses of the second CCD camera 7 and the third CCD camera 8 are all facing the indexing turntable. The first CCD camera 6 , the second CCD camera 7 and the third CCD camera 8 are respectively supported on the machine platform 5 by corresponding brackets.

[0034] Such as figure 1 , figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com