Novel cloth detection device

A new type of fabric detection technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of delaying workers' work, not meeting the production needs of enterprises, and not being smooth enough to improve the production qualification rate, soft and non-dazzling light, and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

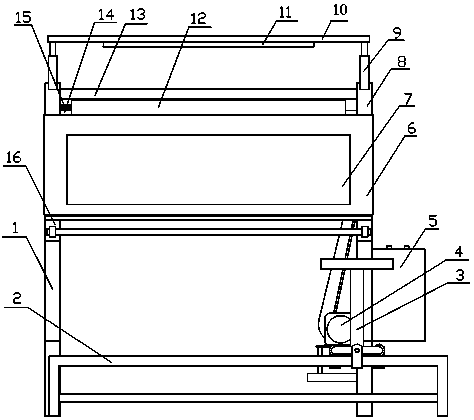

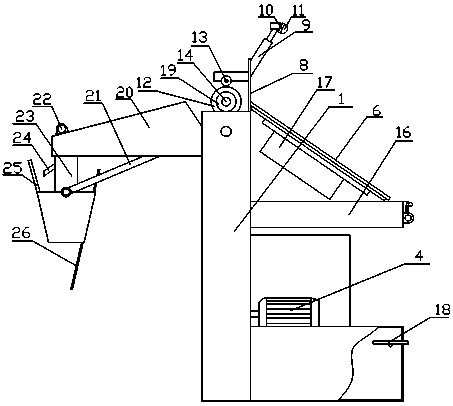

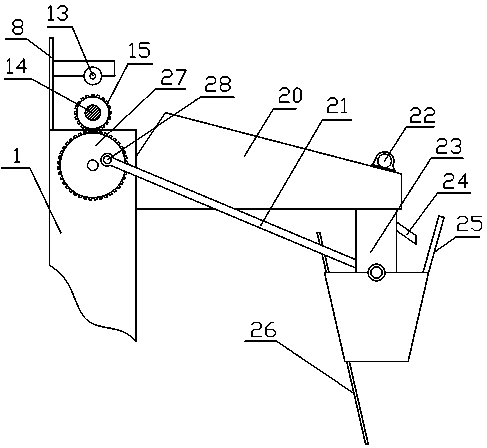

[0020] Such as figure 1 , 2 , 3, 4, and 5 show a new type of cloth inspection equipment, including a cloth inspection frame 1, a sliding seat 2, a mobile table 3, a cloth inspection plate 6, a rotating shaft 14, and a cloth outlet frame 23. The cloth inspection frame 1 means that two left and right sides are placed in parallel, and the support platform 16 is integrally extended from the middle position. The two cloth inspection racks 1 are supported and fixed by a number of fixed rods 22. A sliding seat 2 is placed in front of the cloth inspection rack 1, and the sliding seat 2 The mobile platform 3 is installed on the upper side, and the flip-type pedal 18 is installed between the bottoms of the two cloth inspection frames 1. Its height is equal to that of the sliding seat 2. There is a cloth inspection board 6 with a housing 17 on the top, a number of lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com